Remote control and integration online monitoring intelligent cantilever excavator

A cantilever roadheader, remote control technology, applied in cutting machinery, slitting machinery, earth-moving drilling and other directions, can solve the problems of high labor intensity, smashing injuries, obstructed front line of sight, etc., and achieves good adaptability to working conditions, High reliability and high driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

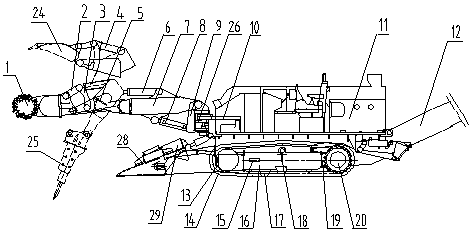

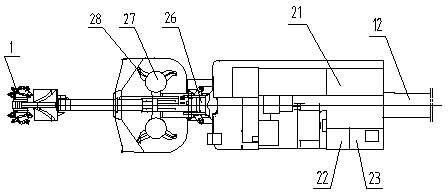

[0015] exist figure 1 and figure 2 Among them, the remote control and integrated online monitoring intelligent cantilever roadheader includes a working mechanism, a traveling mechanism, a transport mechanism, a hydraulic system 21 and an electrical system 11, and the hydraulic system 21 includes a hydraulic motor, a manual reversing valve, a manual pilot Valve, plunger variable pump, coupling, water-cooled radiator, constant temperature oil tank, a load-sensitive hydraulic control multi-way reversing main valve is set in the hydraulic system; the working mechanism includes a cutting head 1 or a bucket 24 or a crushing Hammer 25, chain frame I2, chain frame II3, excavation oil cylinder 4, arm 5, arm oil cylinder 6, arm 7, arm oil cylinder 8, arm seat 9 and rotary oil cylinder, chain frame and cutting head or bucket The quick-change device is used between the breakers or the breakers for quick-change connections. The cutting head, bucket or breaker is connected to the chain fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com