Constant-pressure exhaust braking method and constant-pressure exhaust braking butterfly valve

A technology of exhaust brake and butterfly valve, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc. It can solve the problems of affecting the braking effect, unreasonable and perfect design, and poor product sealing performance, so as to achieve reliable and stable product quality , The product structure is reasonable and ingenious, and the braking effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

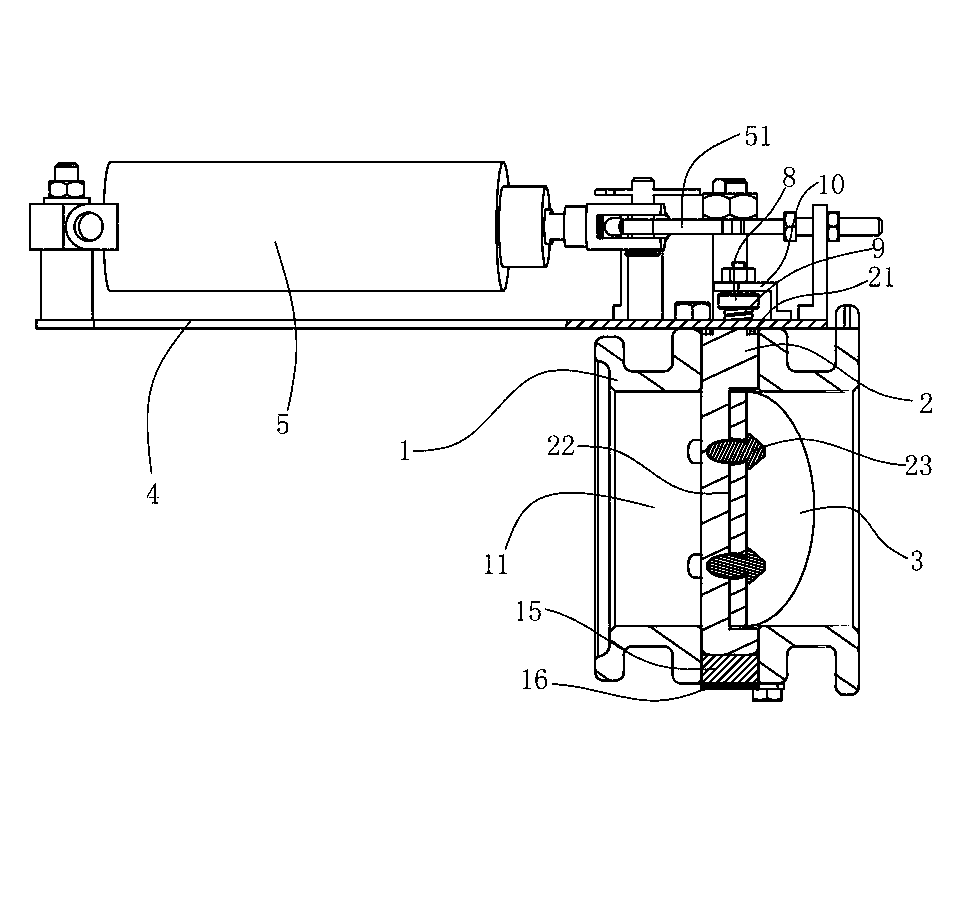

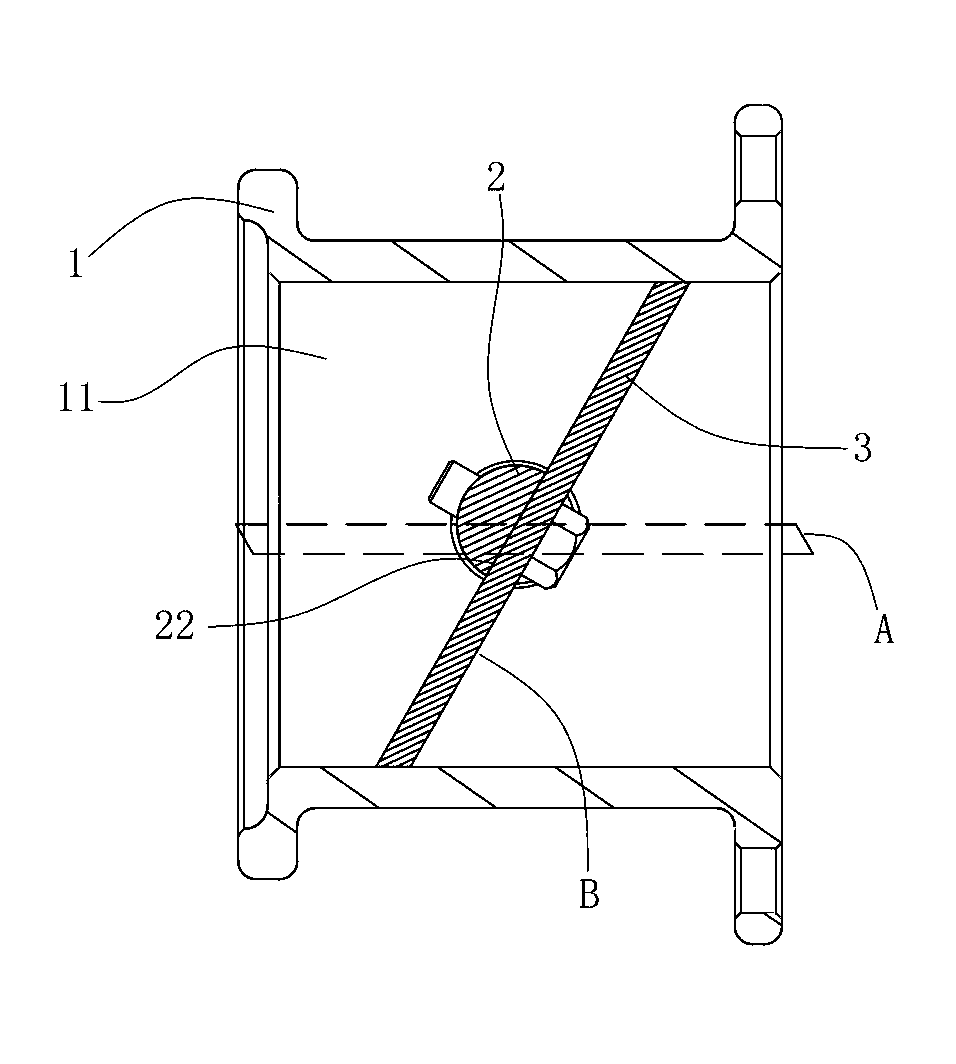

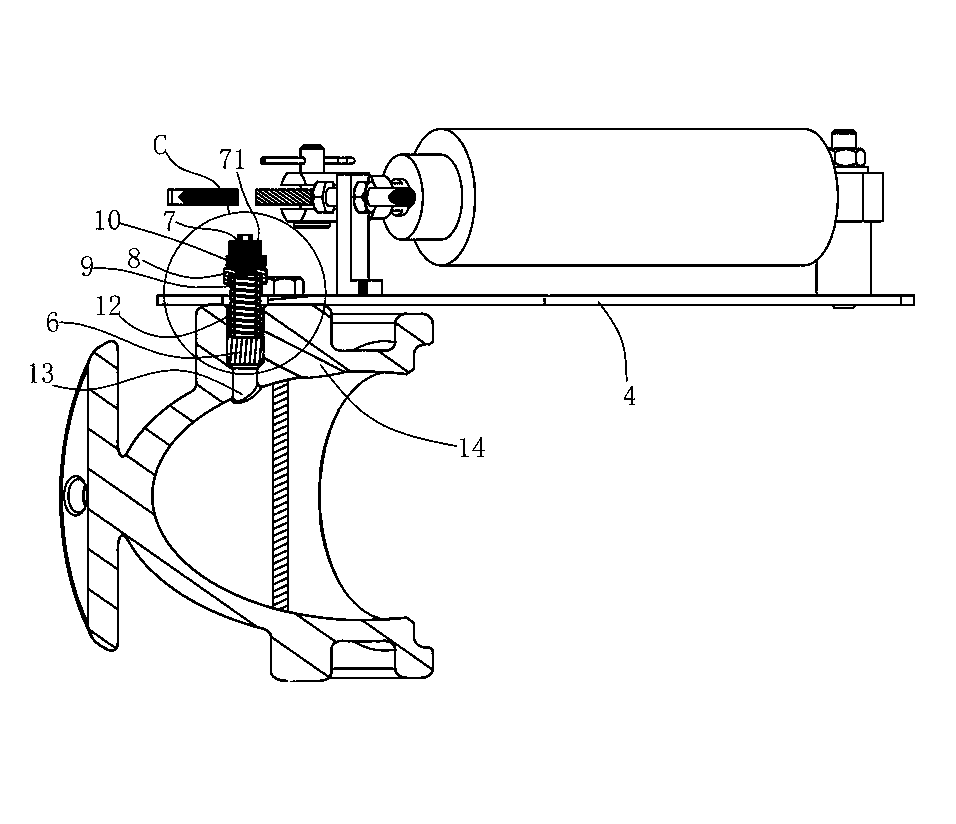

[0029] Example: see Figure 1 to Figure 4 , the present invention is a kind of constant pressure exhaust braking method, and it comprises the following steps:

[0030] (1) A valve body 1 is provided, the valve body 1 is provided with an exhaust passage 11, and a rotating shaft 2 is rotatably set through the valve body 1 on the valve body 1, and a rotating shaft 2 is fixed on the rotating shaft 2. The valve plate 3 with the exhaust passage 11 closed;

[0031] (2) A piston hole 12 is provided at the air inlet end of the valve body 1, an air inlet 13 with a diameter smaller than the piston hole 12 connects the exhaust channel 11 with the bottom of the piston hole 12, and an air outlet hole 14 connects the exhaust channel to the bottom of the piston hole 12. 11 communicates with the side wall of the piston hole 12. When the valve plate 3 closes the exhaust passage 11, the air inlet hole 13 and the air outlet hole 14 are respectively located on one side of the valve plate 3;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com