Sample making method for carbon fiber interlayer shearing strength test, and special die therefor

A carbon fiber layer and shear strength technology, applied in the field of special molds for sample preparation methods, can solve the problems of long process flow, complex process, uneven glue content in sample preparation, etc., to reduce costs, facilitate industrial processing, and have high toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

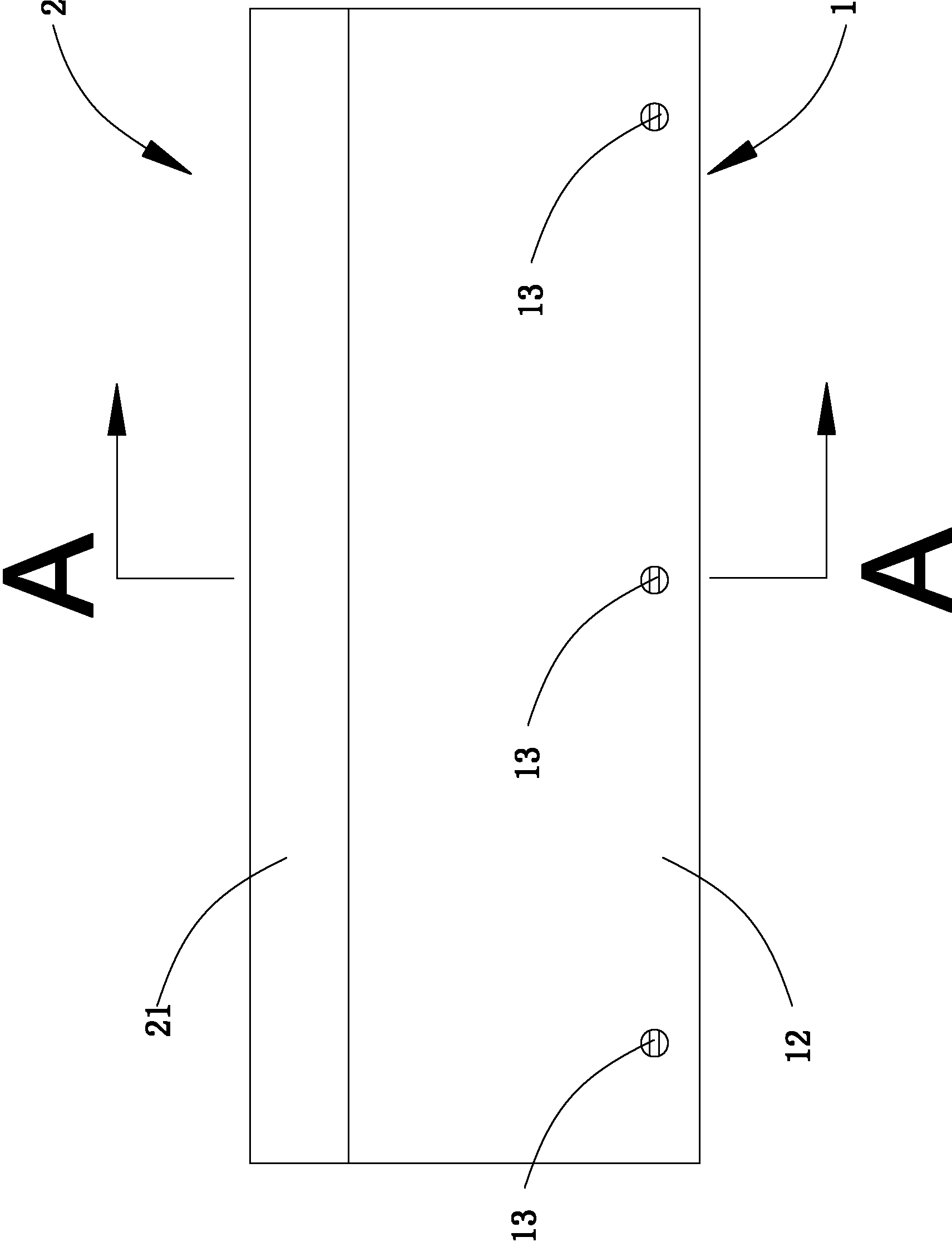

[0042] The sample preparation method of carbon fiber interlaminar shear strength test comprises the following steps:

[0043] Step a): Take 20 carbon fiber tows with a length of 40 cm and spread them on the release paper in turn;

[0044] Step b): Dip the prepared epoxy resin with a brush or a brush with a width of 2-8 cm to paint on both sides of the carbon fiber tow, so that both sides of the carbon fiber tow are evenly coated with epoxy resin;

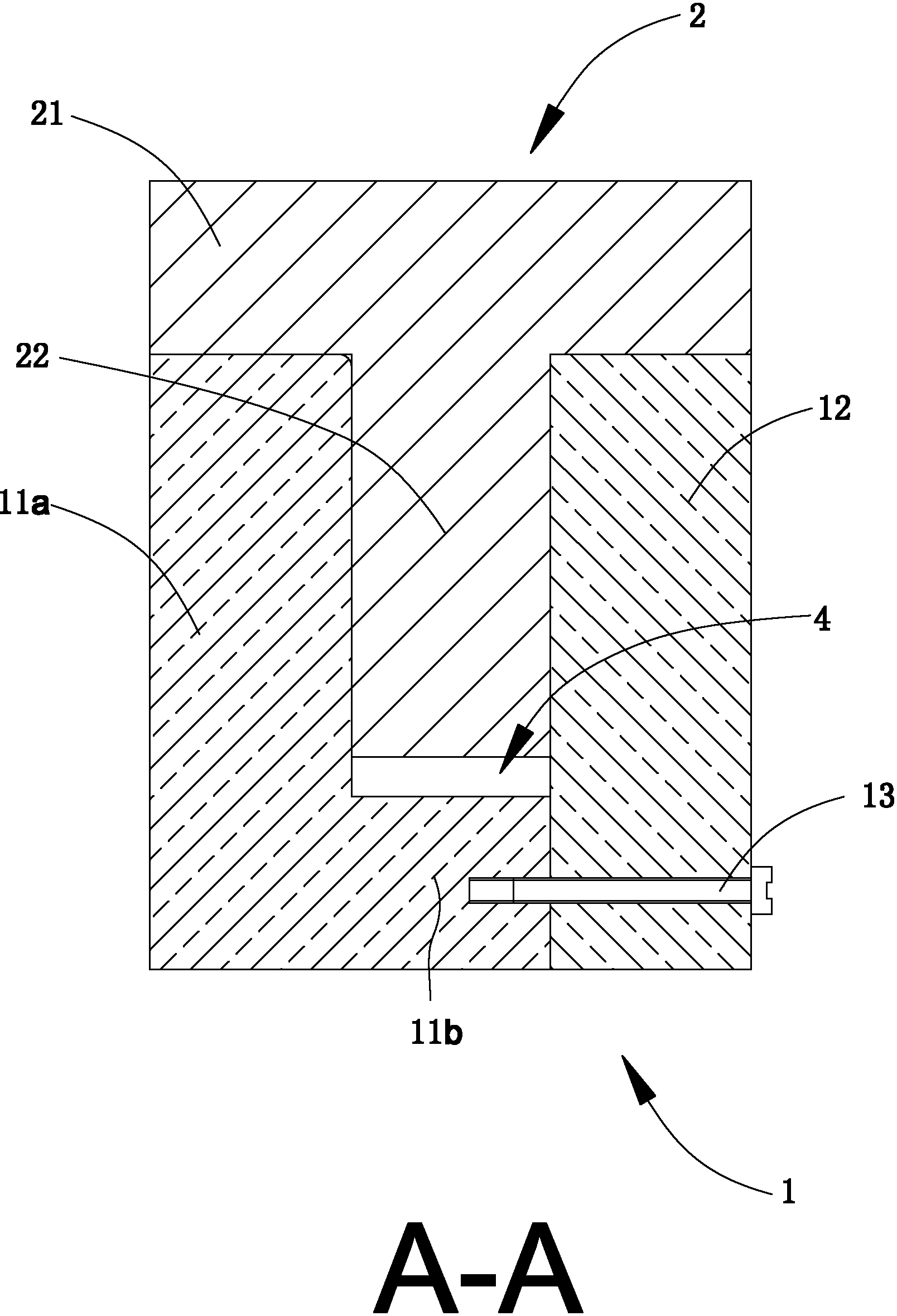

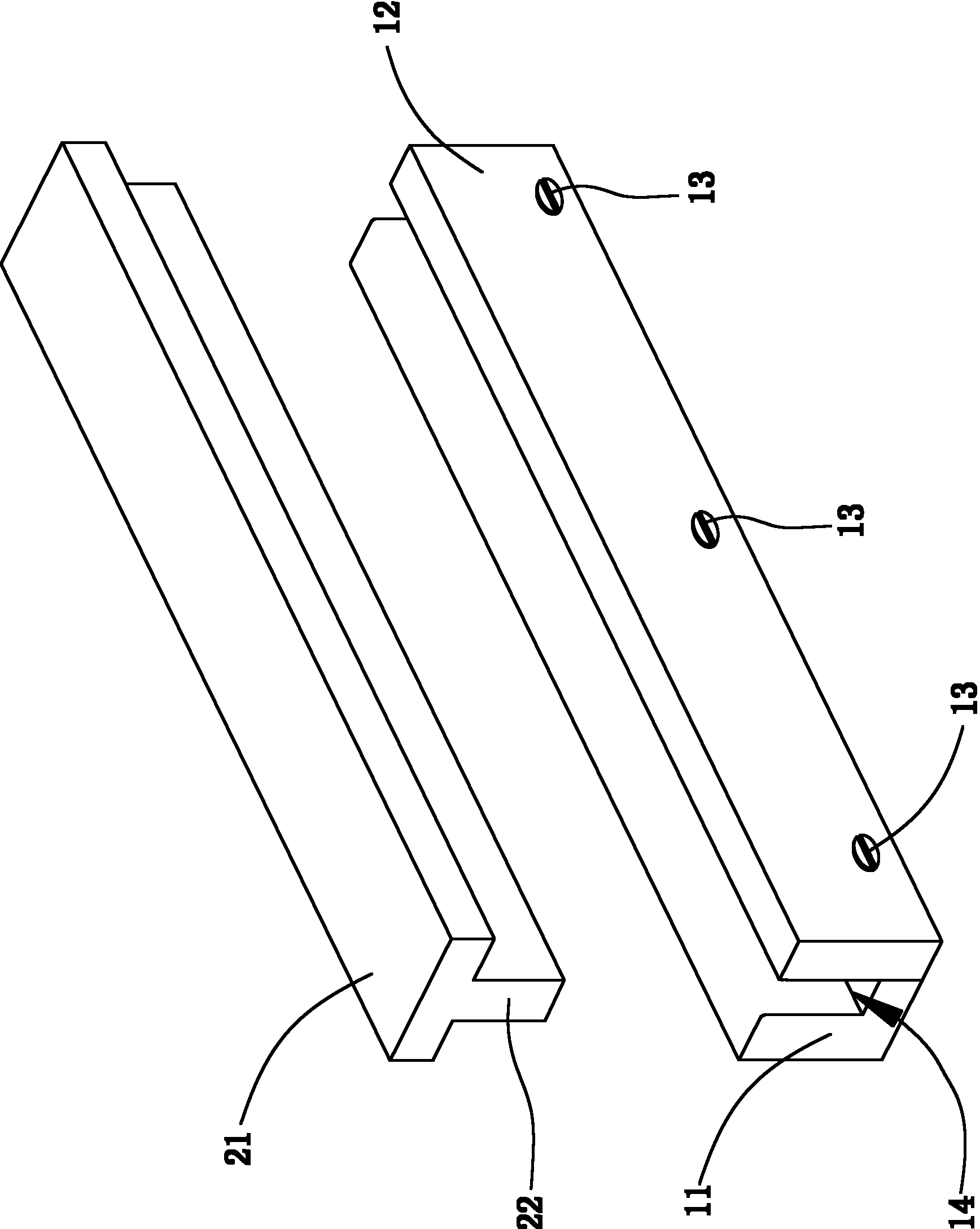

[0045]Step c): first spray the release agent on the groove 14 and the boss 22 of the mold, then put the carbon fiber tow coated with epoxy resin into the groove 14 of the mold with a length of 16cm in turn, and paint the epoxy resin The two ends of the carbon fiber tow of the resin protrude from both sides of the base 1, each carbon fiber tow is manually straightened in turn, and the piston 2 of the mold is matched with the base 1 to squeeze the carbon fiber tow and epoxy resin in the groove 14, Squeeze out the air and excess epoxy...

Embodiment 2

[0050] The sample preparation method of carbon fiber interlaminar shear strength test comprises the following steps:

[0051] Step a): Take 25 carbon fiber tows with a length of 50 cm and spread them on the release paper in turn;

[0052] Step b): Dip the prepared epoxy resin with a brush or a brush with a width of 2-8 cm to paint on both sides of the carbon fiber tow, so that both sides of the carbon fiber tow are evenly coated with epoxy resin;

[0053] Step c): first spray the release agent on the groove 14 and the boss 22 of the mold, then put the carbon fiber tow coated with epoxy resin into the groove 14 of the mold with a length of 20cm, and paint the epoxy resin The two ends of the carbon fiber tow of the resin protrude from both sides of the base 1, each carbon fiber tow is manually straightened in turn, and the piston 2 of the mold is matched with the base 1 to squeeze the carbon fiber tow and epoxy resin in the groove 14, Squeeze out the air and excess epoxy resin ...

Embodiment 3

[0058] The sample preparation method of carbon fiber interlaminar shear strength test comprises the following steps:

[0059] Step a): Take 30 carbon fiber tows with a length of 60 cm and spread them on the release paper in turn;

[0060] Step b): Dip the prepared epoxy resin with a brush or a brush with a width of 2-8 cm to paint on both sides of the carbon fiber tow, so that both sides of the carbon fiber tow are evenly coated with epoxy resin;

[0061] Step c): first spray the mold release agent on the groove 14 and the boss 22 of the mold, then put the carbon fiber tow coated with epoxy resin into the groove 14 of the mold with a length of 24cm, and paint the epoxy resin The two ends of the carbon fiber tow of the resin protrude from both sides of the base 1, each carbon fiber tow is manually straightened in turn, and the piston 2 of the mold is matched with the base 1 to squeeze the carbon fiber tow and epoxy resin in the groove 14, Squeeze out the air and excess epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com