Display device and manufacturing method thereof

A technology for a display device and a manufacturing method, which is applied to equipment for manufacturing conductive/semi-conductive layers, static indicators, optics, etc., can solve the problems of single color, long response time, color filter light loss, etc., and achieves increased application Scene, high contrast, brightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

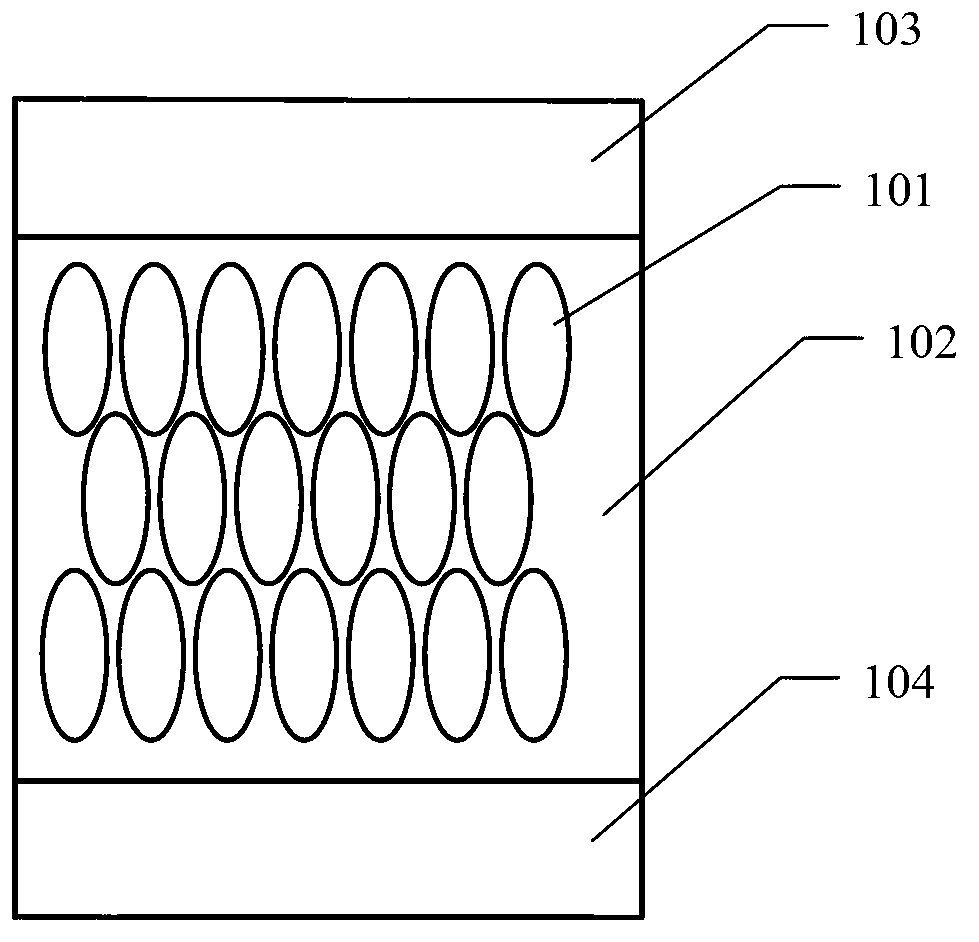

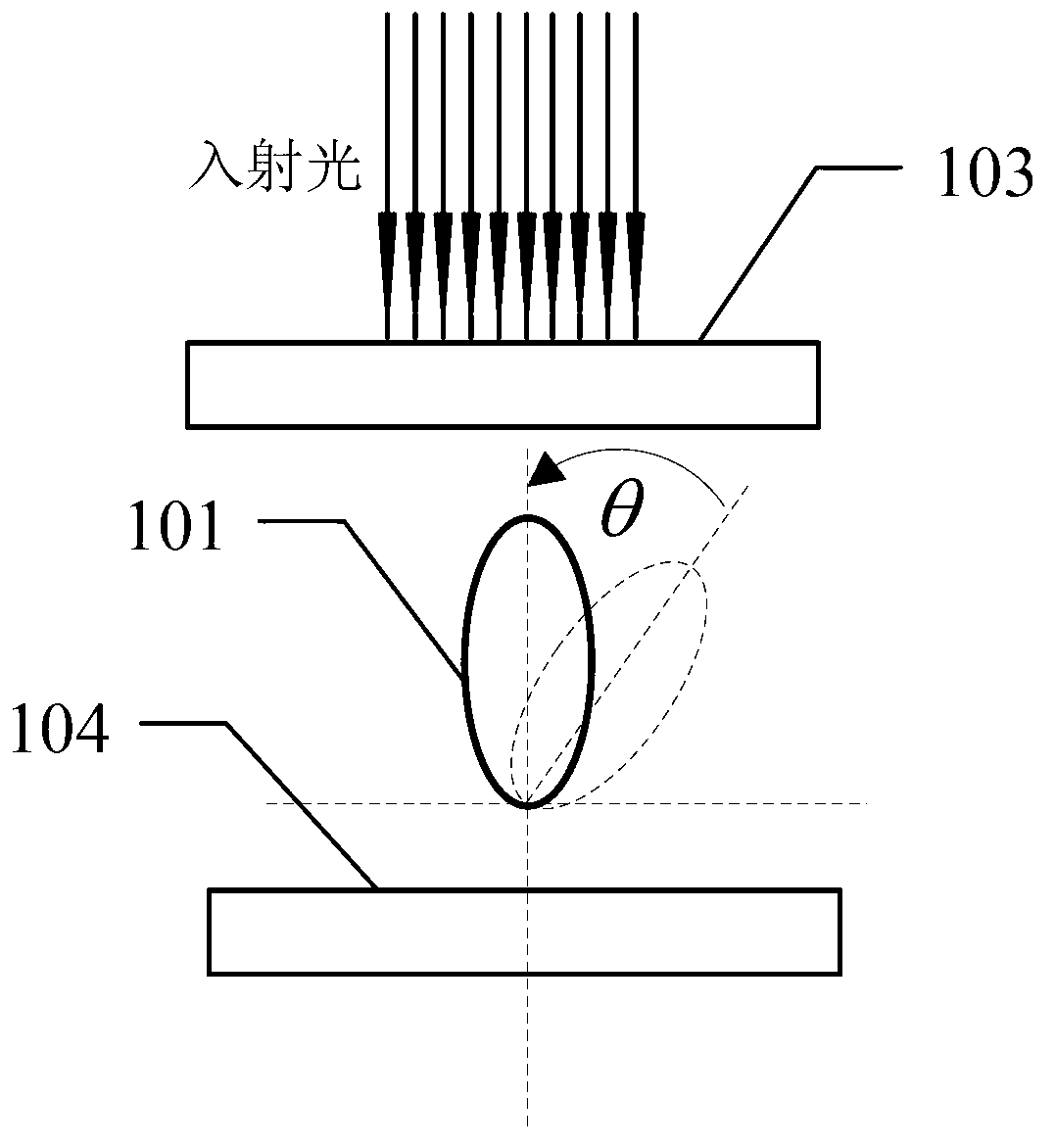

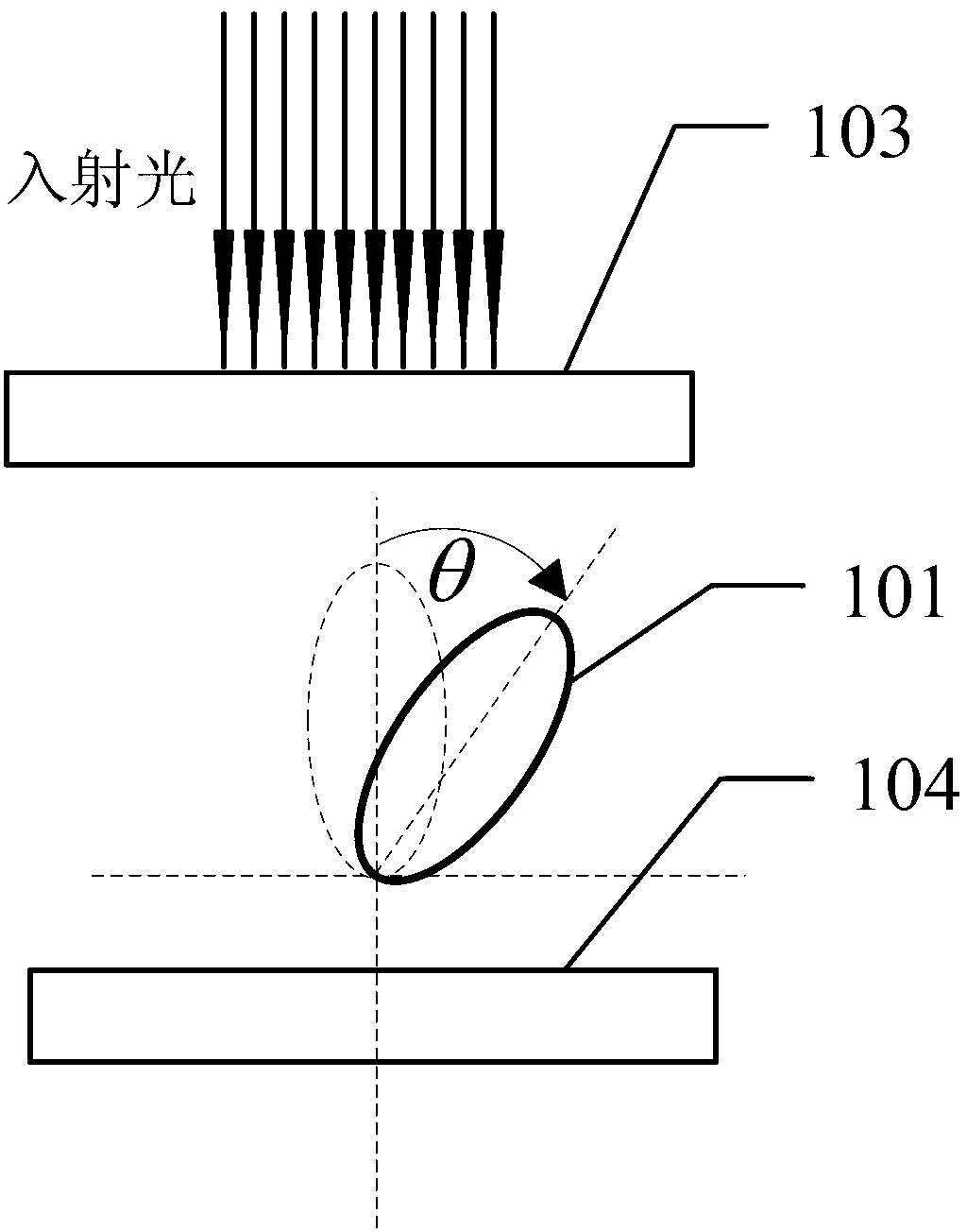

[0047] figure 1 is a schematic structural view of the display device described in the embodiment of the present invention, as shown in figure 1 , a display device provided by an embodiment of the present invention, comprising: an upper substrate 103, a lower substrate 104, and a solvent 102 between them, and also includes: The ellipsoid 101 and the ellipsoid 101 has electromagnetic properties;

[0048] The ellipsoid 101 is a nano-scale or sub-micron-scale micro ellipsoid, and the cross-section of the axis of the ellipsoid is elliptical; the reflected light wavelength of the photonic crystal varies with the distance between the upper substrate 103 and the lower substrate 104 The intensity of the applied electric field or the applied magnetic field changes; the solvent 102 acts to lubricate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com