Steel-concrete composite structure damage measurement system

A combined structure and measurement system technology, which is applied in the direction of measuring devices, material analysis using acoustic wave emission technology, material analysis using sound waves/ultrasonic waves/infrasonic waves, etc. Poor electromagnetic interference ability and other problems, to achieve the effect of improving reliability, good stability and accuracy, and avoiding electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

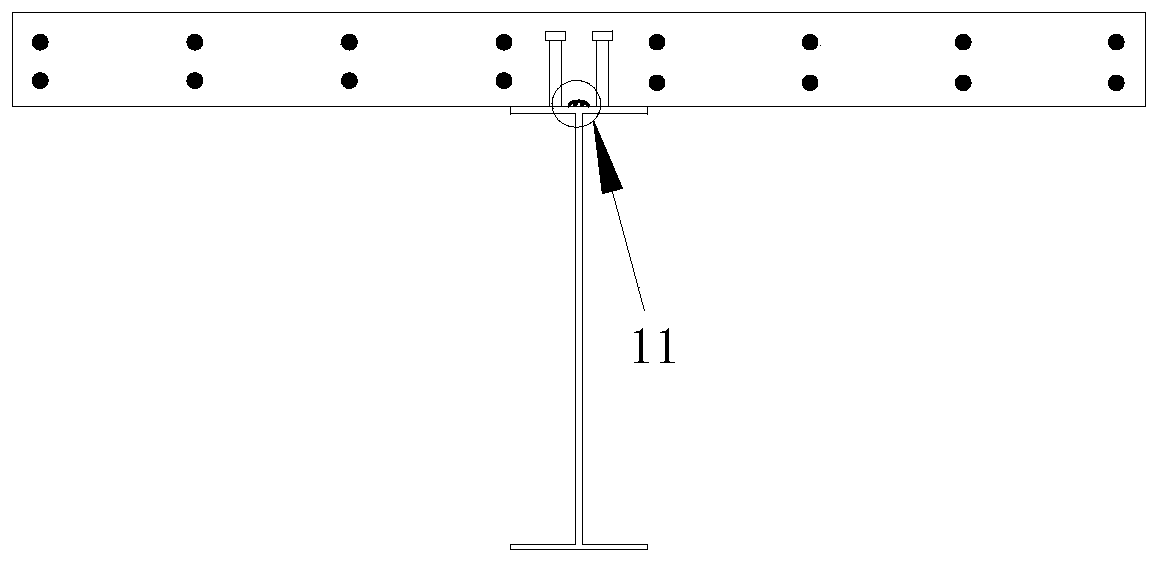

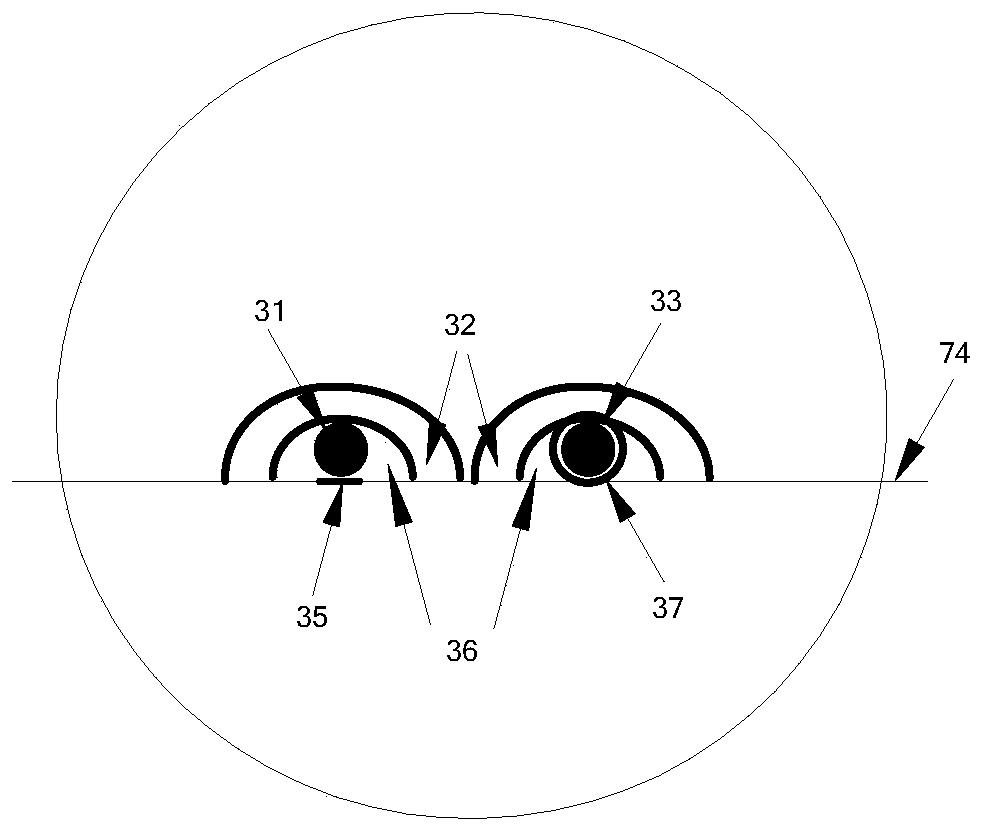

[0055] combined with Figure 1-12 Provide a detailed and complete description of the technical solution.

[0056] The present invention proposes a fiber grating sensing and measuring device applicable to steel girder strain monitoring at the interface of railway steel-concrete bridges, which can accurately measure the strain of steel girders at the interface of railway steel-concrete composite bridges, and effectively evaluate the health status of bridges , Prevent potential safety hazards in advance and avoid major safety accidents.

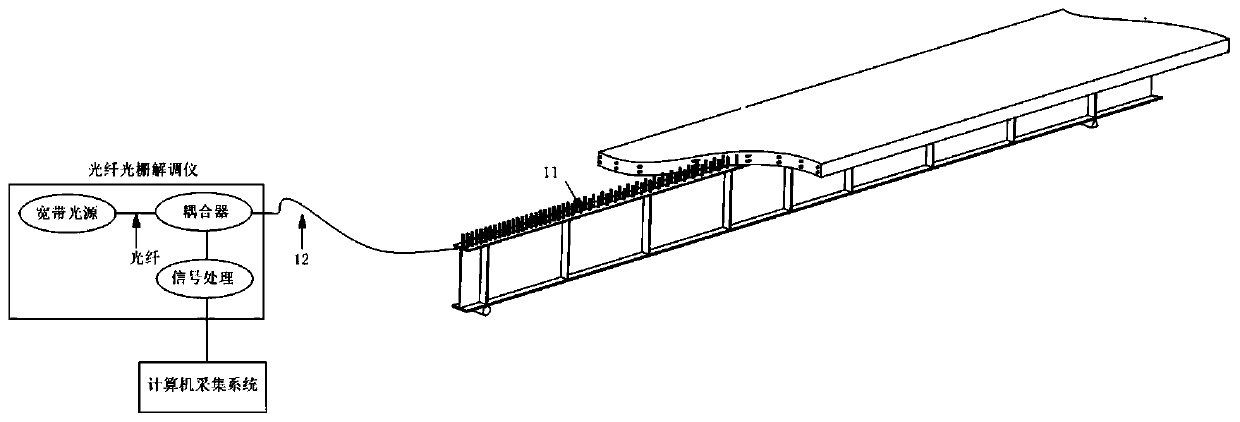

[0057] figure 1 A schematic diagram of the fiber grating measuring device is given, in which the fiber grating measuring element is pasted on the surface of the steel beam at the interface of the steel-concrete composite bridge, connected to the fiber grating demodulator through an optical fiber, and the demodulator processes the emitted light wavelength The information is transmitted to the computing information collection system for analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com