Inductive coupling type high-frequency electrodeless lamp simulation device and method

A technology of inductive coupling and simulation devices, which is applied in the direction of instruments, simulators, control/regulation systems, etc., can solve the problems of high development cost, large difference in working status of electrodeless lamps, and inability to adjust parameters online, so as to achieve reliable technical guarantee, The effect of shortening the development cycle and improving the quality of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

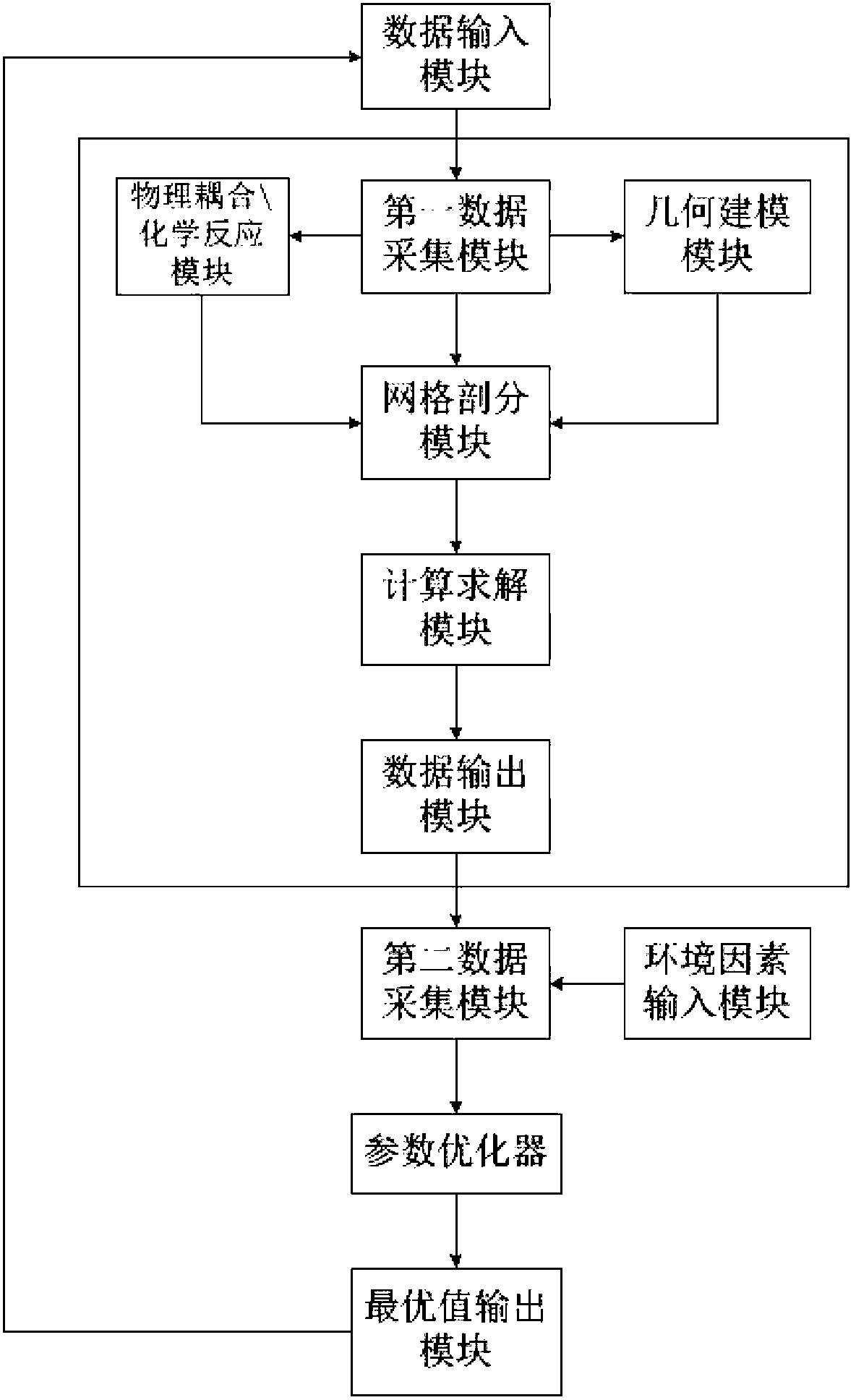

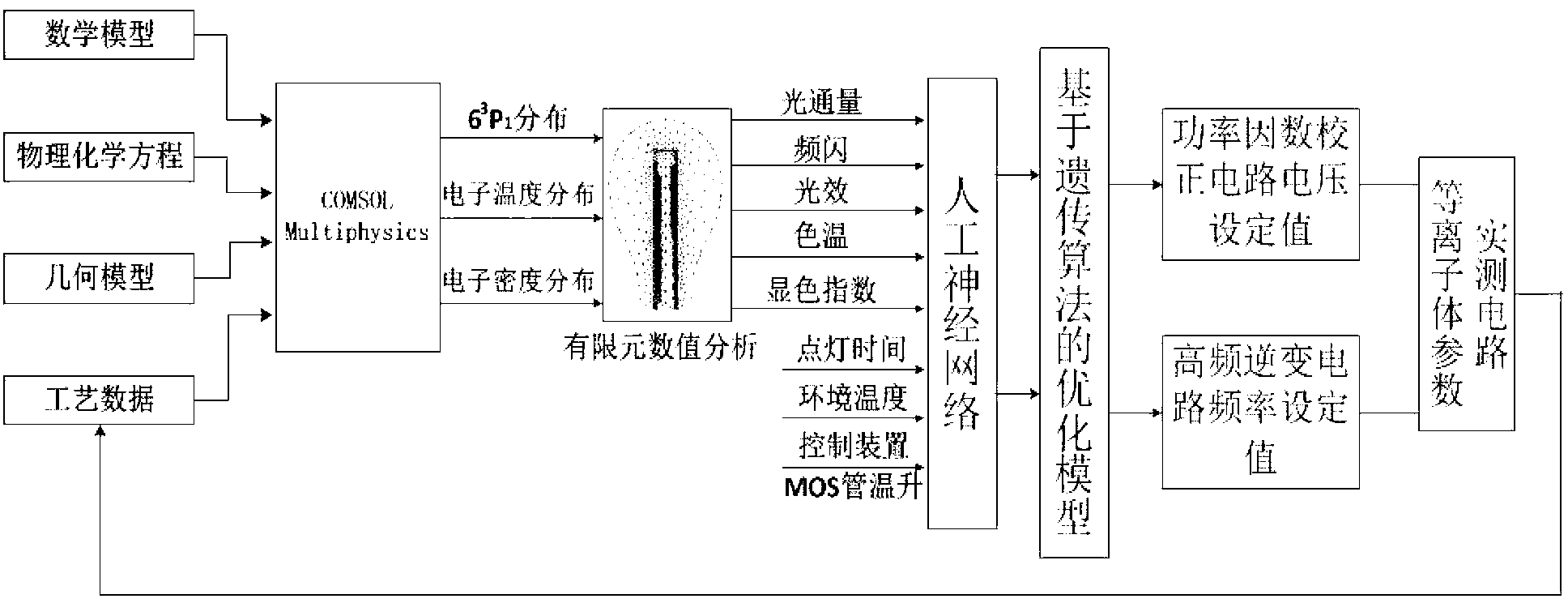

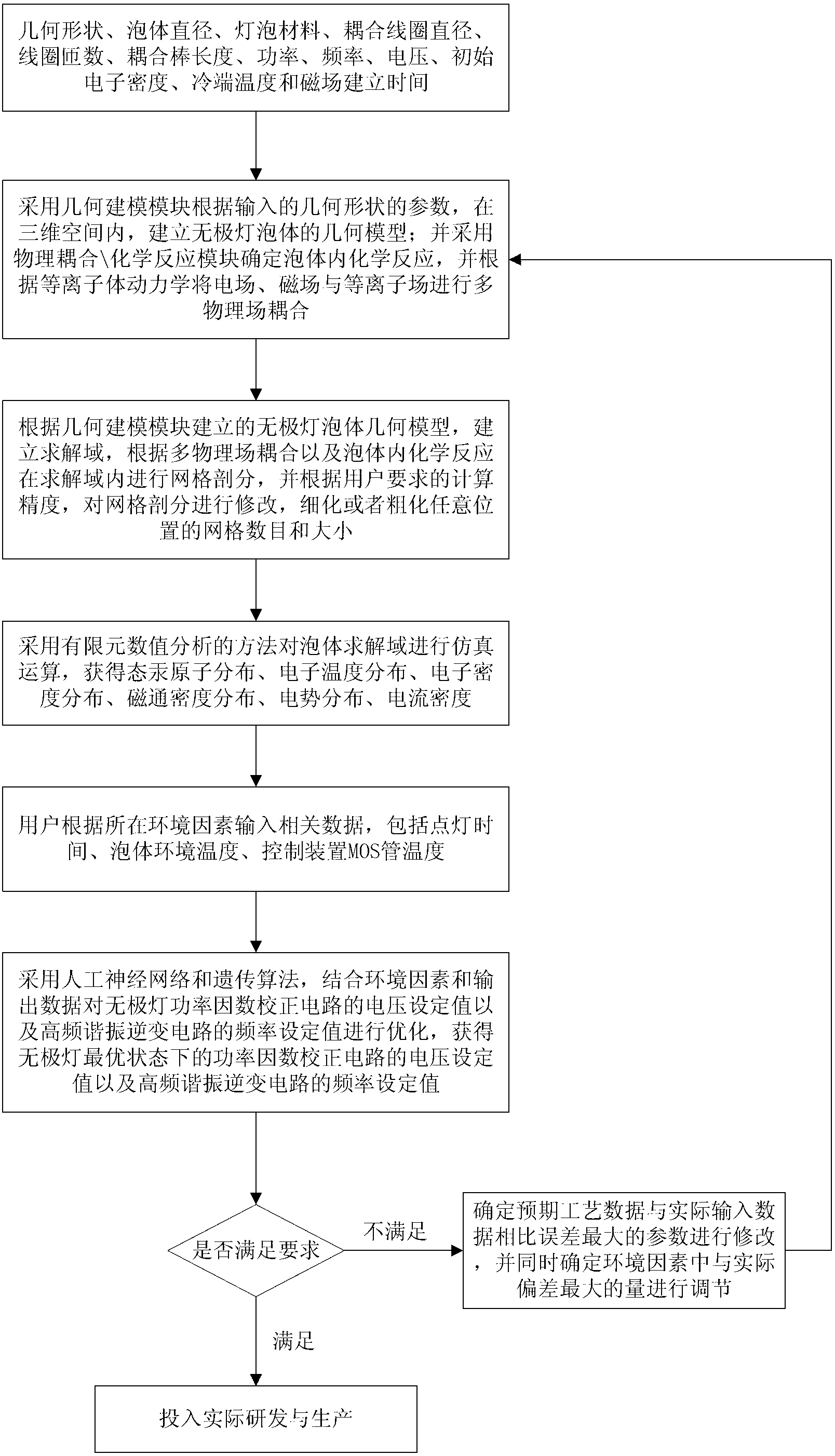

[0041] An inductive coupling type high frequency induction lamp simulation device, such as figure 1 As shown, including data input module, first data acquisition module, geometric modeling module, physical coupling\chemical reaction module, meshing module, calculation solution module, data output module, environmental factor input module, and second data acquisition module , Parameter optimizer and optimal value output module, which is used to set the geometric shape of the electrodeless lamp (olive, pear, ring, spherical), bulb diameter, bulb material, coupling coil diameter, coil turns, coupling rod Length, power, frequency, voltage, initial electron density, cold junction temperature and magnetic field establishment time, and judge the computer grammar rules of the above parameters. If the parameters conform to the grammatical rules, the parameters wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com