Electronic product production line rhythm control system

A technology of electronic products and control systems, applied in the field of control, can solve problems such as rising product failure rate, chaotic production rhythm, and workstations not working properly, so as to improve the qualified rate and avoid accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The accompanying drawings disclose the specific structure of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

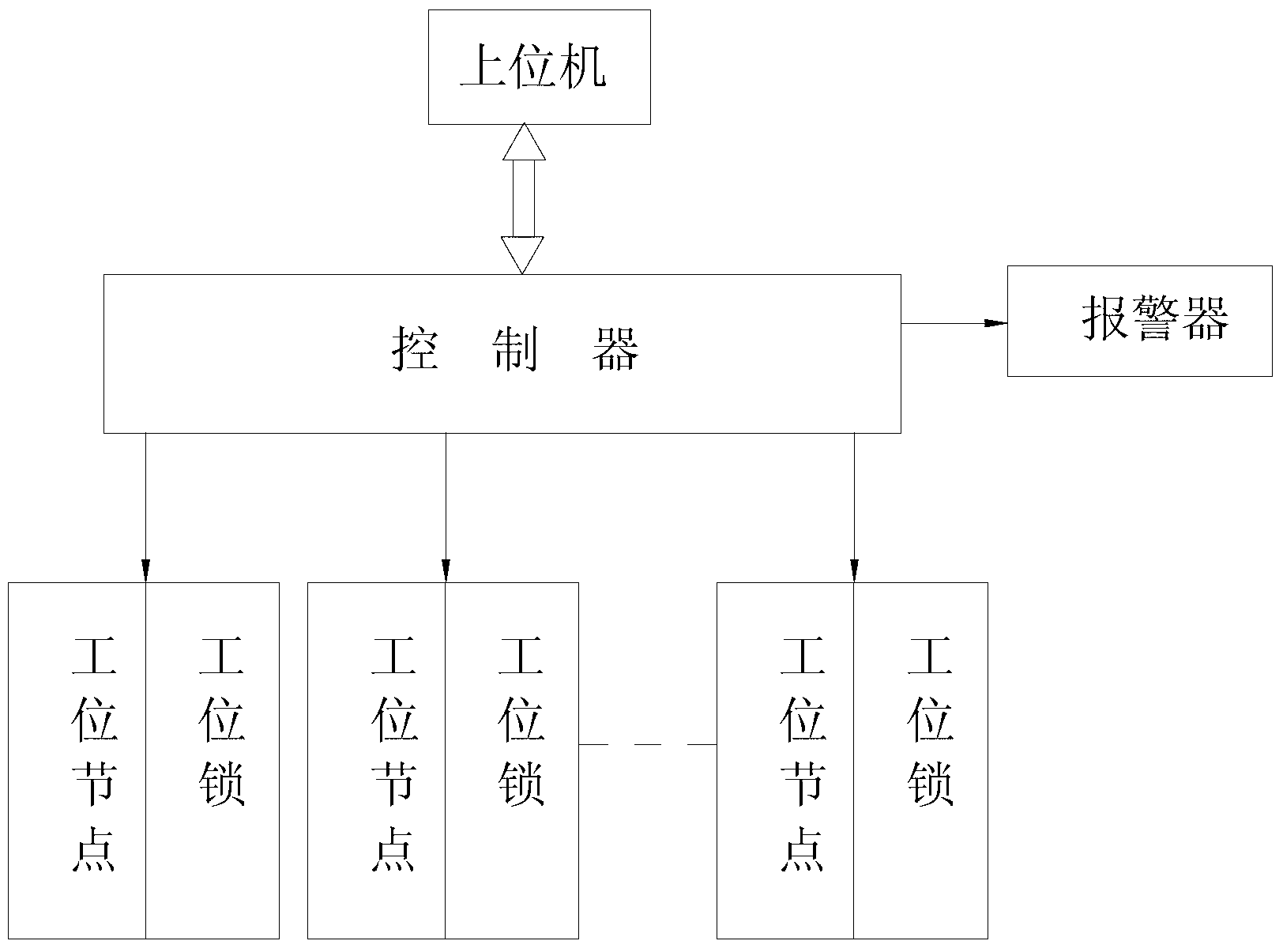

[0015] Such as figure 1 As shown, the electronic product production line rhythm control system includes an upper computer PC, a serial port server, a controller, a station node and a station lock. The upper computer PC is connected to the controller through the serial port server, and the controller is connected to the station node. The bit node is connected to the station lock;

[0016] The controller sends the production rhythm to the station node, and the station lock is in a locked state within the rhythm time. If the station node completes the station work within the rhythm time, the station lock is opened and sends a completed station to the controller. Work signal; if the station node does not complete the station work within the rhythm time, the station l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com