Method for dynamically determining and optimizing parameter importance in manufacturing process of plasma display screen

A plasma display screen and manufacturing process technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., to achieve the effect of improving yield, saving time and resource costs, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

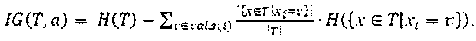

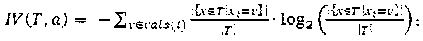

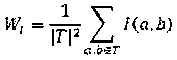

[0015] A method for dynamically determining and optimizing the importance of parameters in a plasma display manufacturing process, comprising the following steps:

[0016] Step 1. According to the date of the production data of the whole process provided by the user, a database of production data of the whole process production process is constructed;

[0017] Step 2. Perform serial processing on the data content of all processes in the whole process, and divide them according to the level or bad type of plasma screens, and divide the plasma screens belonging to a specific level or specific bad type into one group, and other plasma screens into one group. group, and then align the parameters in the production process corresponding to the plasma screens between the groups to form the whole process data;

[0018] Step 3, carry out missing value processing and normalization processing to the whole process data formed in step 2:

[0019] Described missing value processing refers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com