Raw areca nut screening line

A technology for raw fruit and betel nut, applied in the field of betel nut fruit sorting devices, can solve the problems that the betel nut products cannot be guaranteed to have the same quality, the surface of the raw betel nut fruit has many dust and debris, and the working environment is harsh, and the consistency of the quality grade of the betel nut can be achieved. Good, improve the efficiency and quality of screening, reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

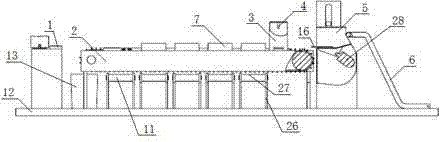

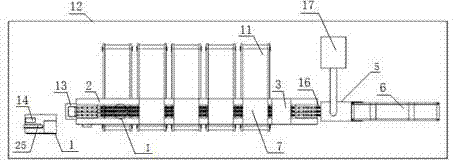

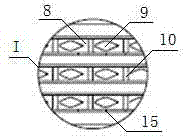

[0018] The raw betel nut screening line of the present invention includes a base 12 and a lifting mechanism 6 arranged on the base 12 , a feeding mechanism 5 , a transmission mechanism, an industrial computer 1 and a material receiving line 11 . The feeding mechanism 5 is composed of a V-shaped transmission trough 16, a vibrator 28 and a dust collector 17 arranged on the support frame. The conveying mechanism is composed of a conveying belt 8 arranged on the conveying support 2 , a detection system 3 , a screening mechanism 7 and a release gate 15 . The conveyor belt 8 is provided with a transverse stopper 10, and the front and rear two transverse stoppers 10 form a square frame with the separating belt on the transmission support 2. The screening mechanism 7 is an electric driving mechanism, which is composed of an electronic driver 18 and a driving piston 19 arranged in the casing 20 . The lifting mechanism 6, the feeding mechanism 5, and the transmission mechanism are conn...

Embodiment 2

[0023] The screening mechanism 7 of the second embodiment is a pneumatic drive mechanism, which is composed of a housing 20, a pipe joint 22 arranged on the housing 20, and a driving hole 21. The pipe joint 22 is provided with a solenoid valve 24, and the pipe joint 22 is connected to a compressed air source. Link, the solenoid valve 24 is connected with the industrial computer 1 by a data bus. All the other are the same as the first embodiment.

[0024] The working process of the second embodiment is the same as that of the first embodiment. When the betel nut 9 reaches the material receiving line 11 of the specified level, the industrial computer 1 sends an instruction to open the release door 15, and the electric door of the electromagnetic valve 24 is opened, and the compressed air enters the air cavity 23 , the betel nut 9 is blown through the drive hole 21 on the housing 20 and falls onto the splicing belt 27 of the splicing line 11 of the specified level, and the betel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com