Three-degree-of-freedom hybrid drive winding type flexible cable parallel mechanism

A hybrid drive, winding technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that the flexible cable cannot be wound and the working space is fixed, and achieve the effect of improving flexibility, increasing bearing capacity, and high bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings.

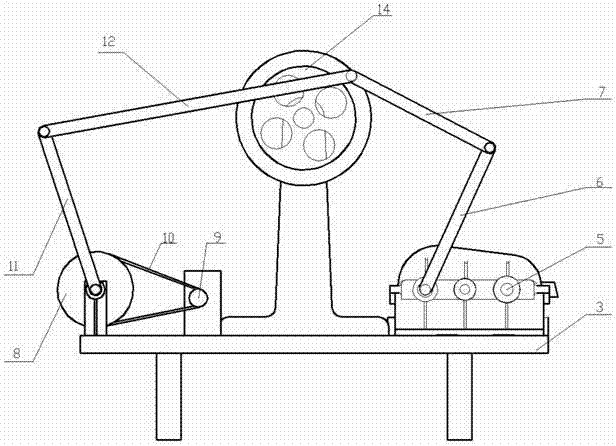

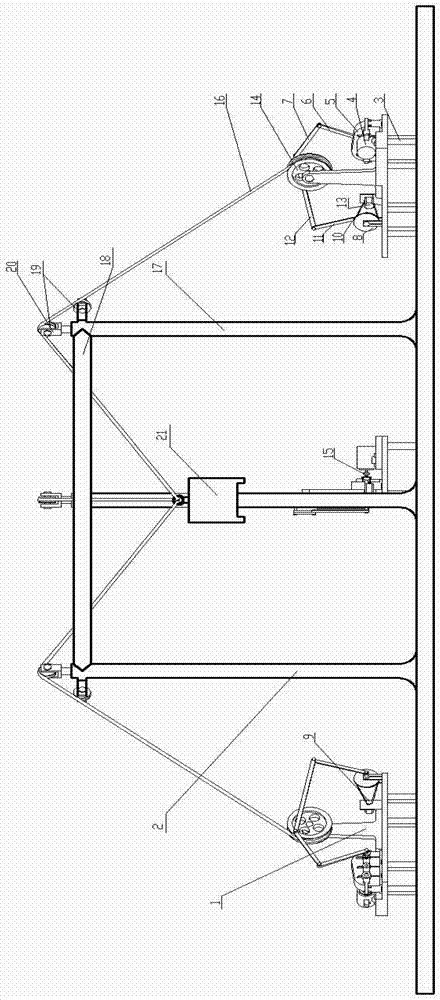

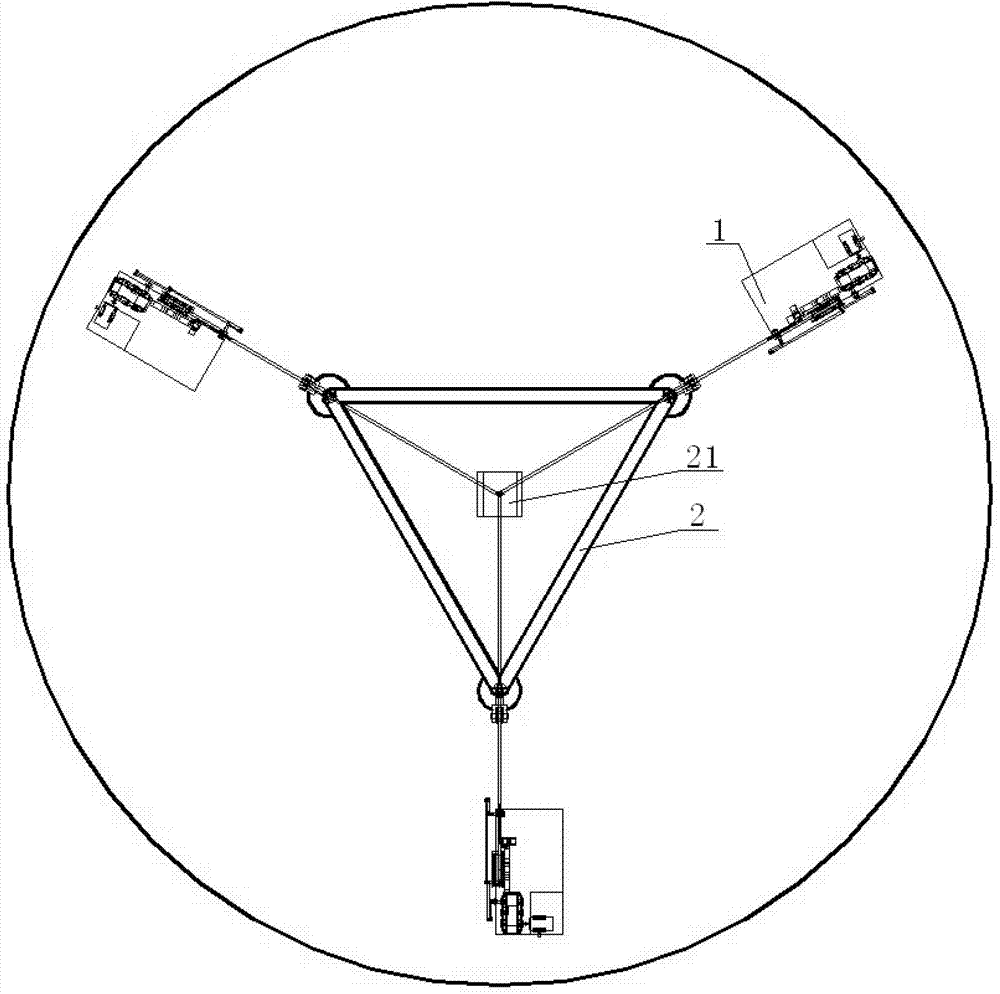

[0023] Such as figure 1 , figure 2 Shown is a three-degree-of-freedom hybrid drive winding type flexible cable parallel mechanism, including three groups of mixed drive five-link winding structure units distributed in a fringe shape 1, a pylon support in a regular triangular prism structure 2, three flexible cables 16 和重物21; The flexible cord 16 is a wire cord.

[0024] The pylon bracket 2 includes three pylon prisms 17 and a pylon beam 18 whose two ends are respectively fixed to two adjacent pylon prisms 17, and a pulley bracket 20 is installed on the upper end of the pylon prism 17 and the pulley bracket 20 can rotate relative to the pylon prism 17; two pulleys 19 are installed on the pulley bracket 20, and there is an angle between the two pulleys 19; the pylon bracket 2 is installed on three sets of hybrid drive five-links The inner side of the winding structure unit 1, and each gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com