Double-buffering inflatable packaging bag and manufacturing method thereof

A double cushioning and packaging bag technology, applied in the field of inflatable packaging bags, can solve the problems of insufficient shockproof effect and other problems, achieve good protection effect, facilitate production and transportation, and have good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

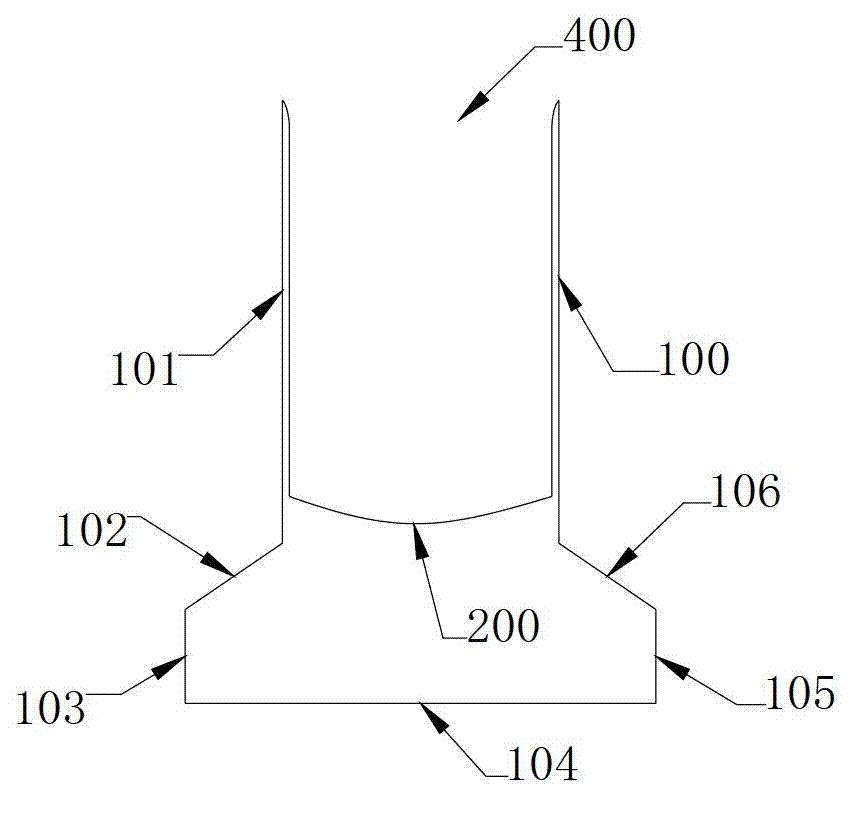

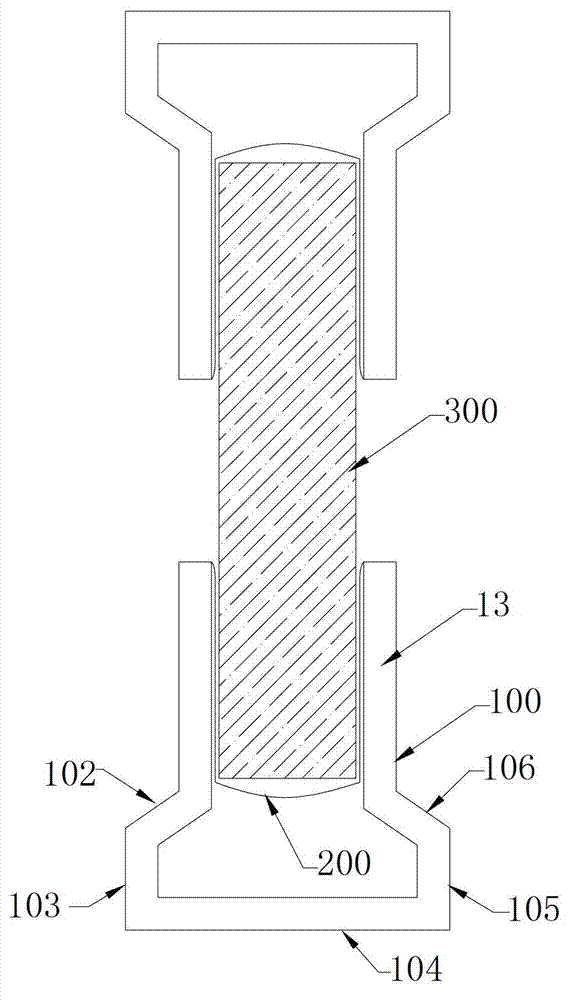

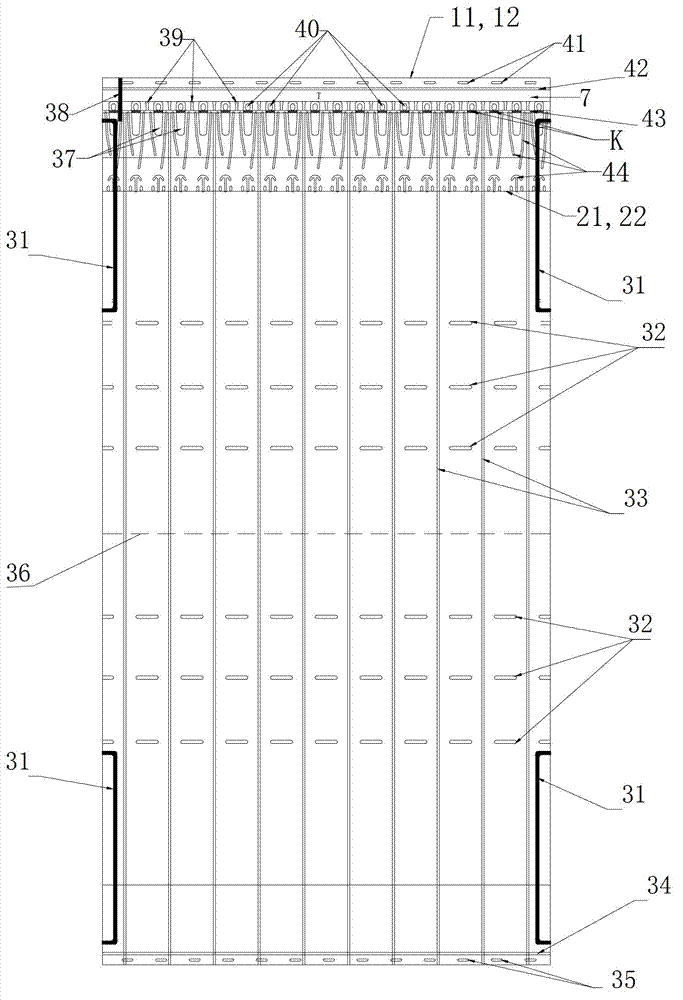

[0038] This embodiment is used as a best implementation mode, combining figure 1 and figure 2 As shown, the double cushioning inflatable packaging bag, the main part is an outer bag 100 formed by an inflatable plastic film, which is provided with an article accommodation cavity and one end is an article insertion port 400. The inflatable plastic film has multiple such as Figure 4 In the strip-shaped inflatable chamber 13 structure shown, each strip-shaped inflatable chamber 13 communicates with the main inflation channel 7 through a one-way check valve; an auxiliary film 200 is also lined inside the article accommodation chamber of the outer bag 100 to form an inner pocket structure, The edge of the auxiliary film 200 is connected with the edge of the article inlet 400 of the outer bag, and the bottom of the auxiliary film 200 has a certain distance from the bottom of the outer bag 100, so that the outer bag 100 is inflated as if figure 2 Its bottom is shown not in contact...

Embodiment 2

[0057] The difference from Example 1 is that no side openings are reserved on the two side edges of the outer bag near the bottom of the bag, and all of them are heat-sealed twice to form an outer bag closed on three sides, such as Figure 6 As shown, what this embodiment forms is that there is a suspended lining auxiliary film 200 inside the outer layer bag 100, and the upper part is an article insertion port 400. The structure is simple, and the impact energy for the bottom of the bag is from the bottom along the outer layer bag 100 to Items are delivered in the direction of the mouth, and then the goods are delivered through the lining auxiliary film 200. Although the cushioning effect is slightly lower than that of embodiment 1, it is still much better than the protective effect of directly packaging the goods with only the outer bag 100. The air columns formed by the inflatable chamber 13 are arranged vertically to improve the vertical pressure bearing capacity.

Embodiment 3

[0059] Such as Figure 7 , the air chamber 13 of the outer bag 100, that is, the direction of the air column, is set horizontally. This way is used in commodities such as Figure 7 When placed in the manner shown, the rigidity of the side wall of the bag is slightly lower at the same specifications of the inflatable chamber and the inflation pressure, and it is easy to bend under the pressure of the product, and the impact resistance is reduced, and the protection effect on the impact of the bottom is lower than that of the bag. figure 2 and Figure 6 However, it is still much better than the method without using the auxiliary film 200 in the air. The item insertion port 400 is used for inserting items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com