Preparation method of fenbendazole

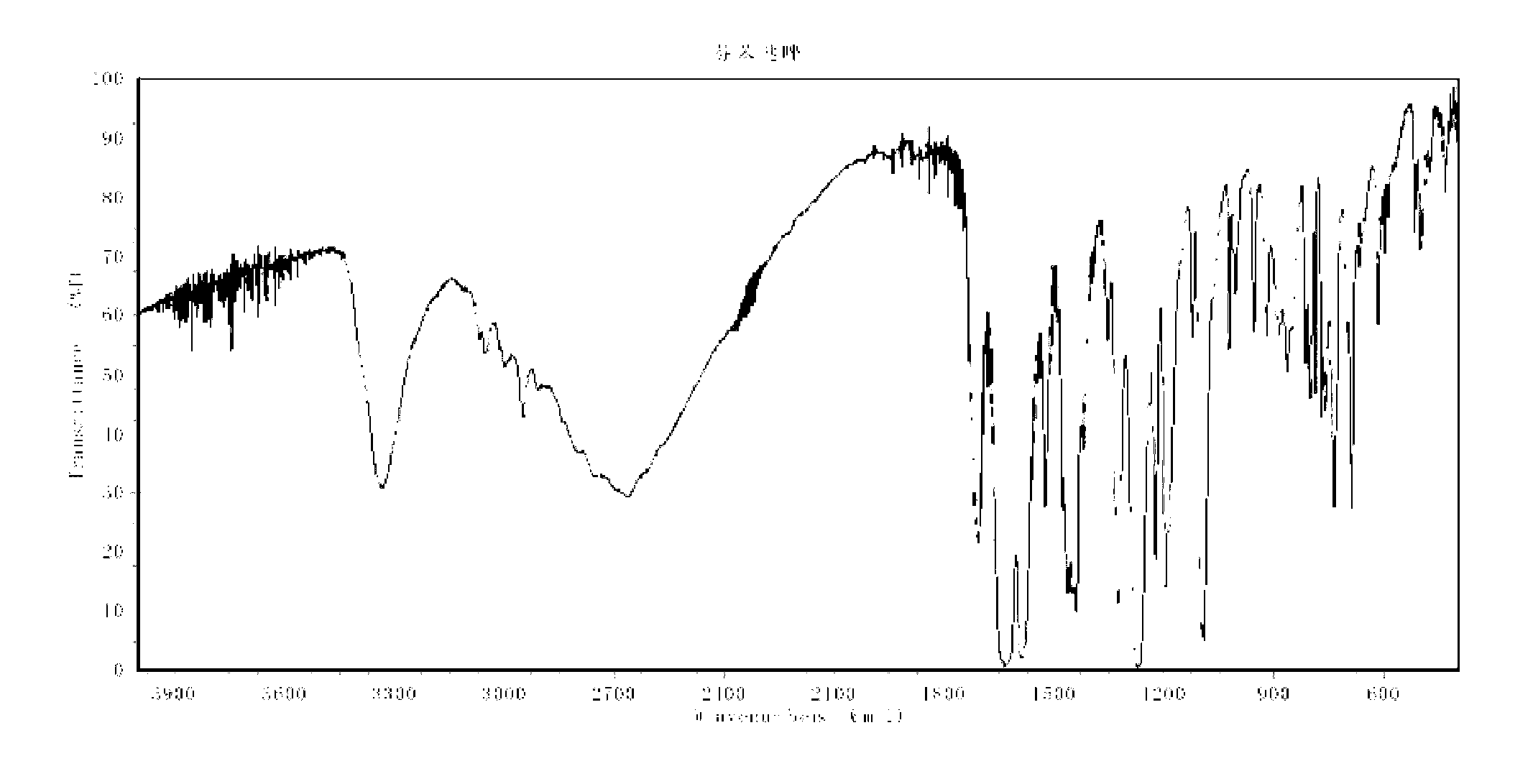

A technology of fenbendazole and a new method, which is applied in the field of preparation of fenbendazole, can solve the problems of low condensation yield, and achieve the effects of high quality, less pollution, and a new synthetic process that is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

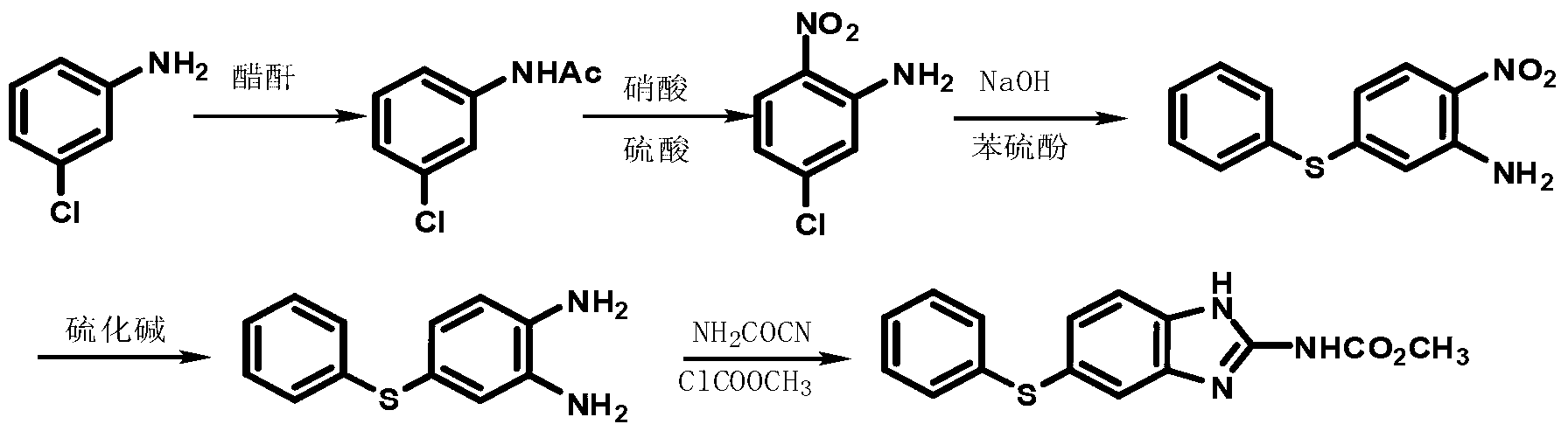

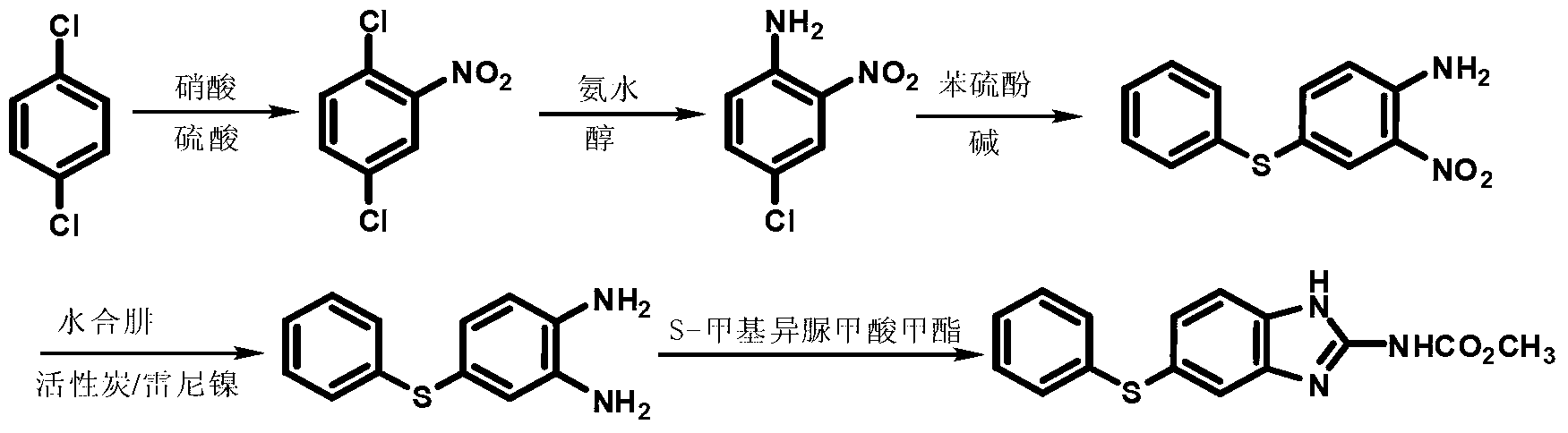

Method used

Image

Examples

Embodiment 1

[0033] Step 12, the preparation of 4-dichloronitrobenzene

[0034] In a 500ml four-necked flask with a thermometer and a stirring device, start stirring, add 100.0g m-dichlorobenzene, 0.5 times the weight ratio of concentrated sulfuric acid, drop nitric acid in a molar amount that is 1.05 times m-dichlorobenzene, and control the dropping temperature at 10-15°C, after the dropwise addition is completed, keep the temperature at 10-15°C for 3 hours, follow the reaction by HPLC, remove the lower waste acid layer, add 100g of 15% sodium carbonate aqueous solution, stir and wash, and separate the lower layer to obtain 2,4- Dichloronitrobenzene 127.0g was directly used in the next step reaction. This step yield is 97.2%, and content is 98.1%.

[0035] Preparation of step 22-chloro-4-phenylthionitrobenzene

[0036] In a 500ml four-necked flask with a thermometer and a stirring device, start stirring, add 90.8g of 2,4-dichloronitrobenzene, 1.02 times the molar amount of thiophenol, a...

Embodiment 2

[0045] Step 12, the preparation of 4-dichloronitrobenzene

[0046] In a 500ml four-neck flask equipped with a thermometer and a stirring device, start stirring, add 100.0g m-dichlorobenzene, 0.9 times the weight ratio of concentrated sulfuric acid, and the molar amount is 1.1 times m-dichlorobenzene nitric acid, and keep warm at 5-10°C After 3 hours, HPLC traced the reaction to be complete. The lower waste acid layer was separated, and 100 g of 5% sodium hydroxide aqueous solution was added to stir and wash. The lower layer was separated to obtain 125.0 g of 2,4-dichloronitrobenzene, which was directly used in the next reaction. This step yield is 95.7%, and content is 98.7%.

[0047] Preparation of step 22-chloro-4-phenylthionitrobenzene

[0048] In a 500ml four-necked flask with a thermometer and a stirring device, start stirring, add 90.8g of 2,4-dichloronitrobenzene, 1.5 times the molar amount of thiophenol, and 3 times the amount of 2,4-dichloronitronitrobenzene Toluene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com