Degradable starch-degradable chromium-containing leather pulp composite as well as preparation method and application thereof

A technology for degrading starch and complexes, applied in application, leather impregnation, small raw hide/large hide/leather/fur treatment, etc., can solve the problems of uneven starch modification, high production cost, poor oxidation selectivity, etc. Excellent effect, rapid reaction, moderate effect of temperature and pressure reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

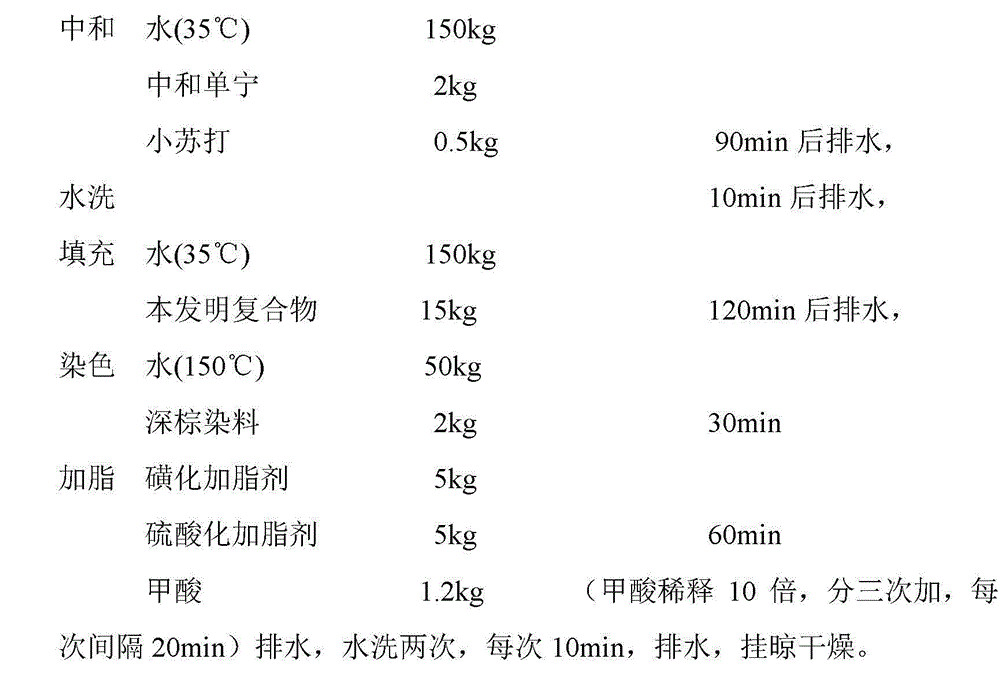

Examples

Embodiment 1

[0032] 1) Add 40 parts of starch, 10 parts of hydrochloric acid with a concentration of 12 mol / L, 10 parts of water, and 3 parts of cerium nitrate into the reaction kettle, mix well, and bake at 80°C for 60 minutes under the protection of nitrogen to obtain light Yellow paste starch degradation product;

[0033] 2) Put 30 parts of dander containing 1.5% chromium trioxide dry weight into the reaction kettle, add 45 parts of water and 2 parts of non-ionic surfactant, stir and degrease at 30°C for 60 minutes, drain water, and add water 30 parts, 10 parts of sodium peroxide, heated up to 90°C for oxidative degradation, and stirred for 90 min to obtain a water-soluble slurry product partially degraded from hexavalent chromium-containing collagen;

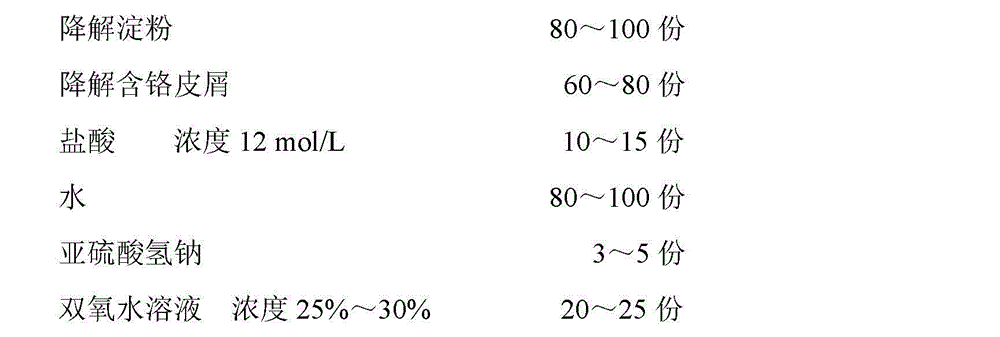

[0034] 3) Add 80 parts of the above-mentioned degraded starch, 60 parts of degraded chromium-containing dander, 10 parts of hydrochloric acid with a concentration of 12 mol / L, 80 parts of water, and 20 parts of hydrogen peroxide with a c...

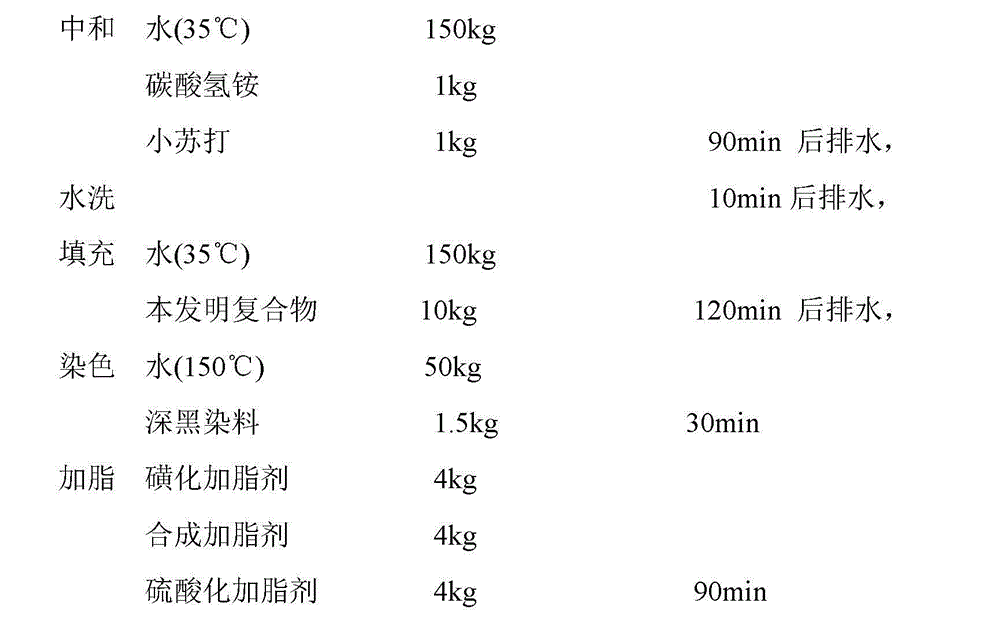

Embodiment 2

[0038] 1) Add 60 parts of starch, 15 parts of hydrochloric acid with a concentration of 12 mol / L, 15 parts of water, and 5 parts of lanthanum nitrate into the reaction kettle. After mixing evenly, bake at 90°C for 90 minutes under the protection of nitrogen to obtain light Yellow paste starch degradation product;

[0039] 2) Put 40 parts of skin flakes containing 2.5% chromium trioxide dry weight into the reaction kettle, add 60 parts of water, 4 parts of non-ionic surfactant, stir and degrease at a temperature of 50°C for 90 minutes, drain water, and add water 40 parts, 15 parts of sodium peroxide, heated up to 110°C for oxidative degradation, and stirred for 120 min to obtain a water-soluble slurry-like product containing part of hexavalent chromium degraded skin collagen;

[0040] 3) Add 100 parts of the above-mentioned degraded starch, 80 parts of degraded chromium-containing dander, 15 parts of hydrochloric acid with a concentration of 12 mol / L, 100 parts of water, and 25...

Embodiment 3

[0044] 1) Add 50 parts of starch, 12 parts of hydrochloric acid with a concentration of 12 mol / L, 12 parts of water, and 4 parts of yttrium nitrate into the reaction kettle. Yellow paste starch degradation product;

[0045] 2) Put 35 parts of dander containing 2.5% chromium trioxide dry weight into the reaction kettle, add 50 parts of water and 3 parts of non-ionic surfactant, stir and degrease at 40°C for 80 minutes, drain water, and add water 35 parts, 12 parts of sodium peroxide, heated up to 100°C for oxidative degradation, stirred for 100 min, and obtained a water-soluble slurry product containing part of hexavalent chromium degraded by skin collagen;

[0046]3) Put 90 parts of the above-mentioned degraded starch, 70 parts of degraded chromium-containing dander, 12 parts of hydrochloric acid with a concentration of 12 mol / L, 90 parts of water, and 22 parts of hydrogen peroxide with a concentration of 28%, and put them into a reactor with a stirrer, at a temperature of 90 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com