Raw coal treatment method and equipment

A processing method and processing equipment technology, which is applied in the direction of combustion method, combustion equipment, lighting and heating equipment, etc., can solve the problems of low dehydration rate of lignite and strong reabsorption of water, and achieve the goal of reducing energy consumption and improving comprehensive utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

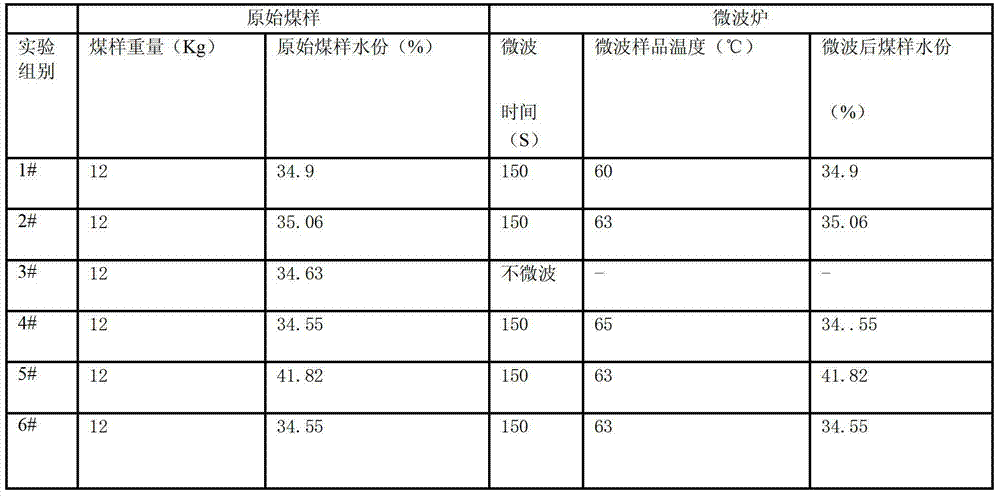

[0042] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

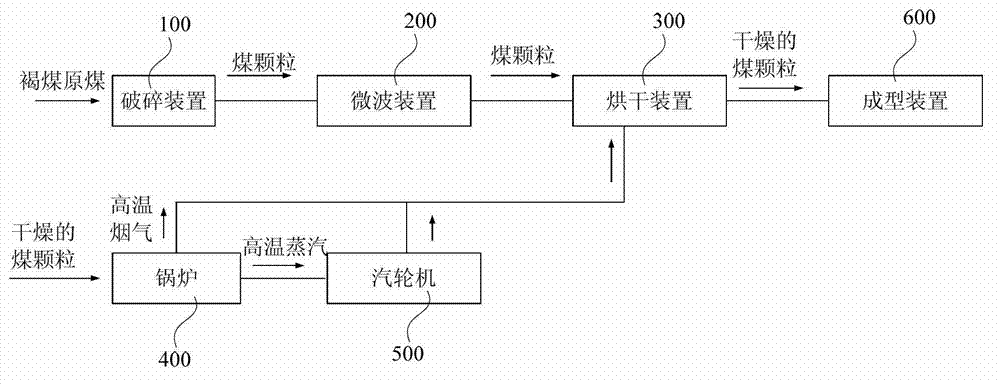

[0043] Aiming at the problems of low dehydration rate and strong water absorption capacity of lignite in the currently used lignite drying and upgrading technology, the present invention provides a raw coal processing method. The raw coal is first modified by microwave and then dried. The device achieves the effect of drying and dehydration. The dehydration rate is high, and long-term storage will not return moisture and absorb water. For lignite treatment, the calorific value of the raw coal after drying can be increased by at least 1000kcal / kg, and the calorific value has been greatly improved, making low calorific value lignite Become a high calorific value power fuel.

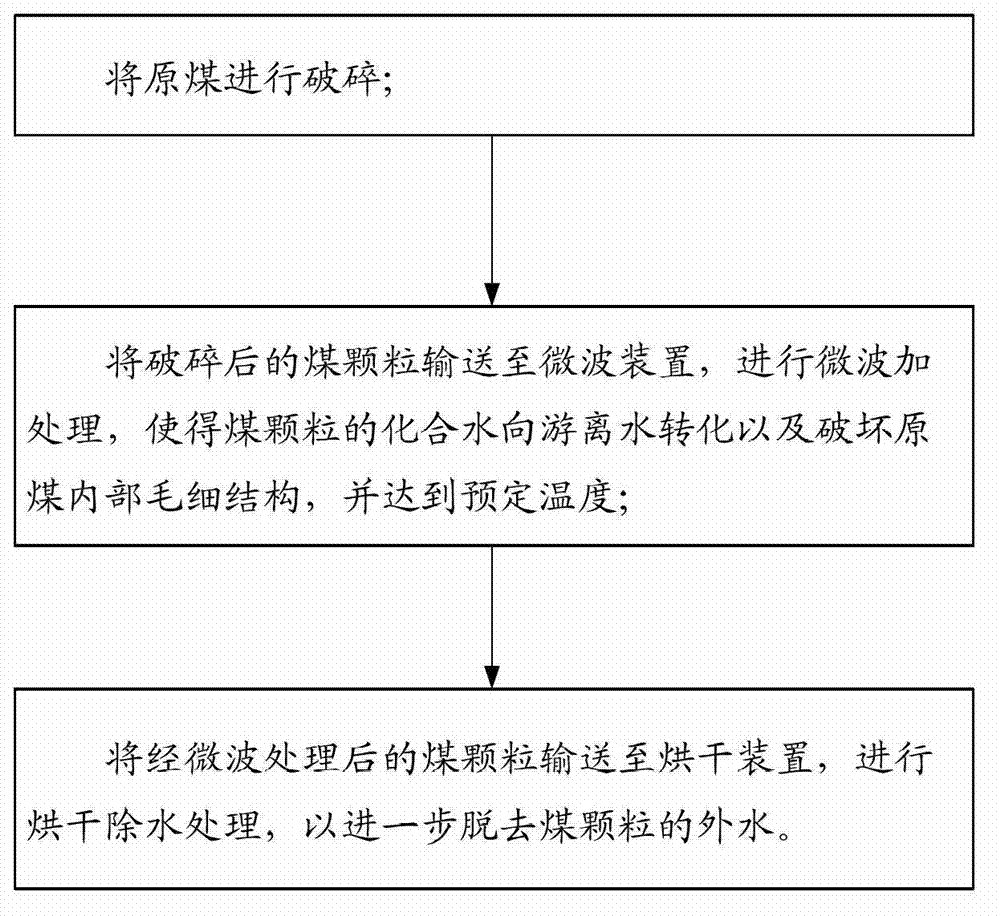

[0044] The method provided by the present invention i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com