A conductive cathode structure on the side of an aluminum electrolytic cell for reducing the horizontal current of aluminum liquid

A horizontal current, aluminum electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve the problems of cell life safety and hidden dangers of cell life, unsatisfactory effect, stress and conductivity changes, etc., to reduce cell voltage and facilitate low pole distance production , The effect of electric field optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

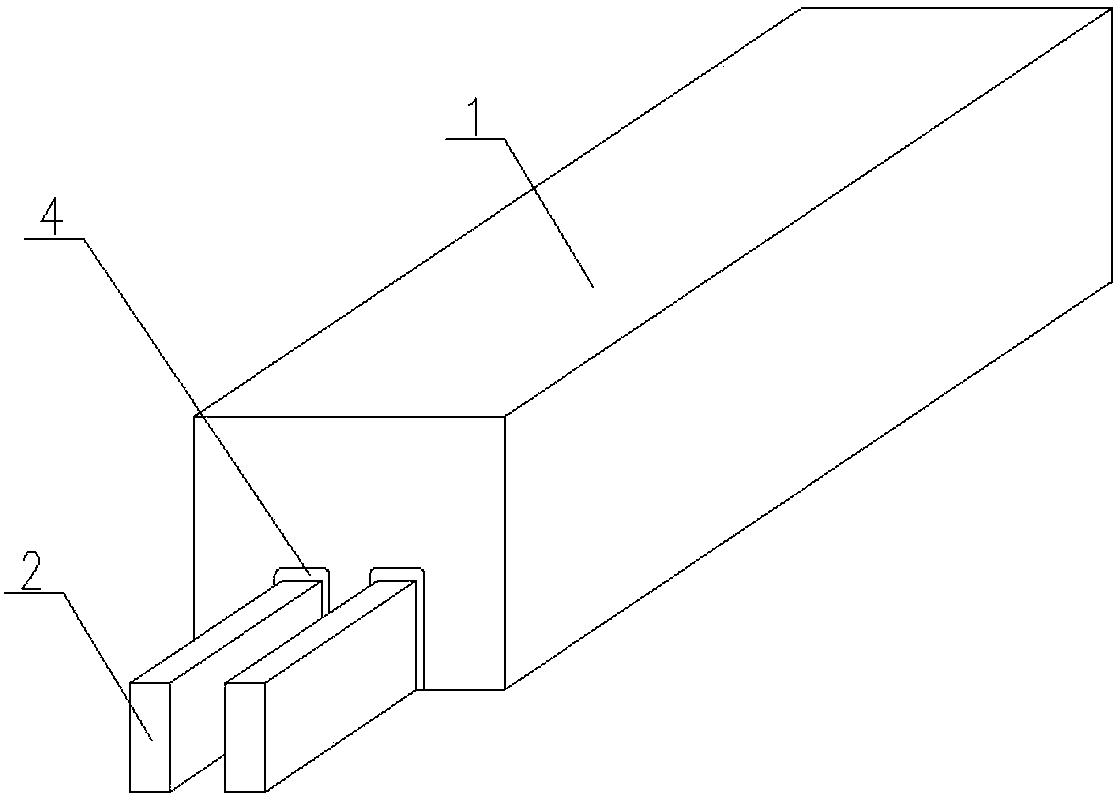

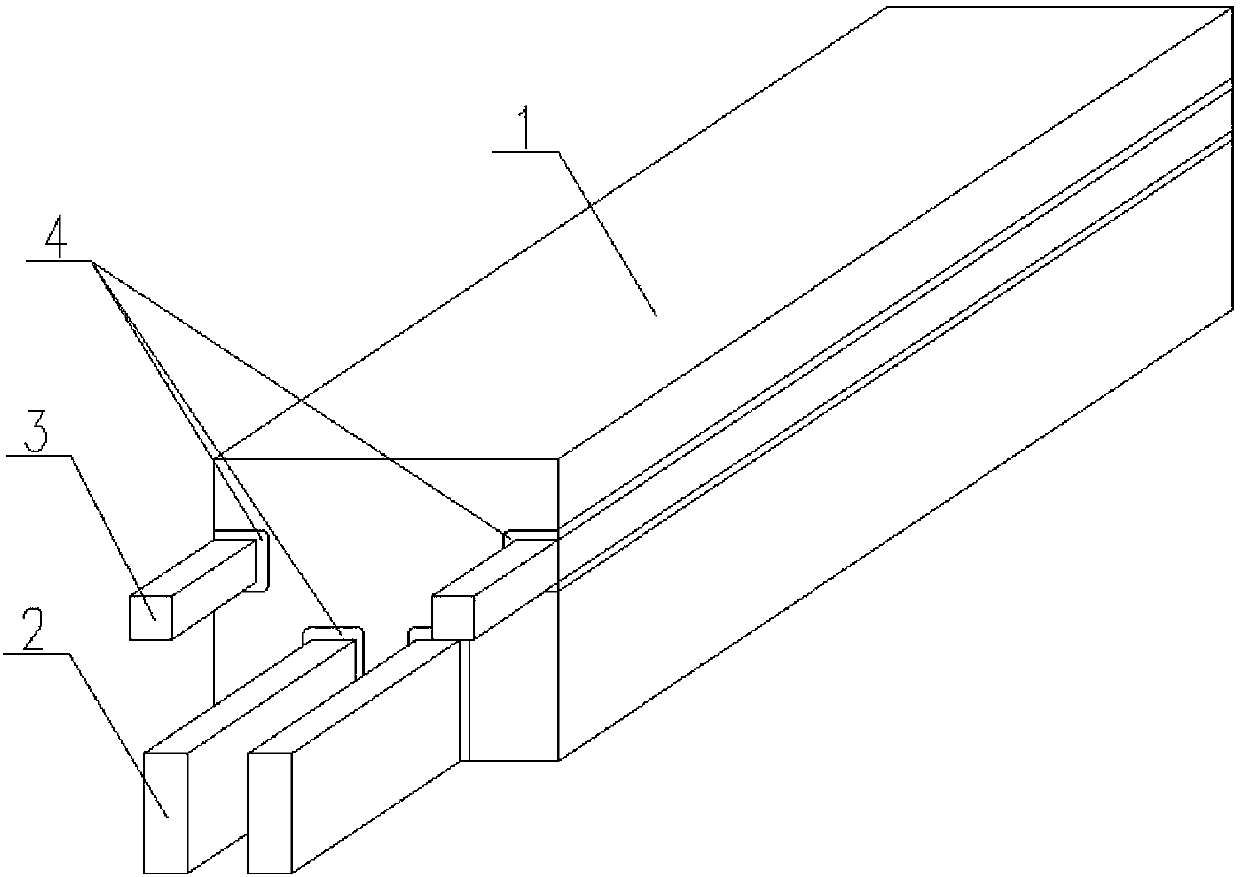

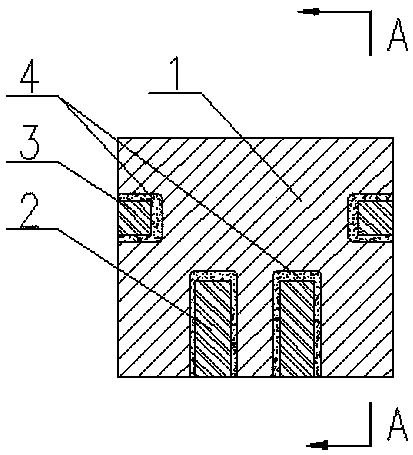

[0037] like figure 2 , image 3 and Figure 4Shown is the schematic diagram of the semi-cathode structure of the aluminum electrolytic cell using the long and horizontally arranged side cathode steel rods of the present invention, which is composed of a cathode carbon block 1, a bottom cathode steel rod 2, a side cathode steel rod 3 and a steel rod carbon block. The paste consists of 4. In this embodiment, the total length of the cathode carbon block 1 is 3000-4000 mm, the width is 400-800 mm, and the height is 400-700 mm; the cathode carbon block 1 has two parallel dovetail grooves of equal cross-section at the bottom, and a corresponding dovetail groove is embedded in each dovetail groove. The bottom cathode steel rod 2 with full length or non-universal length of equal cross-section, the bottom cathode steel rod 2 is 50mm-90mm wide and 50mm-200mm high, and its material, processing and installation methods are the same as those of traditional cathode steel rods; cathode ca...

Embodiment 2

[0040] like Figure 5 , Image 6 and Figure 7 Shown is a cross-sectional view of the semi-cathode structure of an aluminum electrolytic cell using a long and inclined side cathode steel rod of the present invention, consisting of a cathode carbon block 1, a bottom cathode steel rod 2, a side cathode steel rod 3 and a steel rod carbon The paste consists of 4. In this embodiment, the total length of the cathode carbon block 1 is 3000mm-4000mm, the width is 400mm-800mm, and the height is 400mm-700mm; two dovetail grooves of equal cross-section are opened at the bottom of the cathode, and a dovetail groove of equal cross-section is embedded in each of the dovetail grooves. The bottom cathode steel rod 2 of full length or non-full length, the bottom cathode steel rod 2 is 50mm~90mm wide and 50mm~200mm high, and its material, processing and installation method are the same as those of the traditional cathode steel rod; the two sides of the cathode carbon block 1 There is an incl...

Embodiment 3

[0042] like Figure 8 , Figure 9 and Figure 10 Shown is a three-dimensional schematic diagram and a cross-sectional view of the semi-cathode structure of an aluminum electrolytic cell using a single steel bar at the bottom, a long side portion and horizontally arranged side cathode steel bars of equal cross-section according to the present invention. The side cathode steel rod 3 and the steel rod carbon paste 4 are composed. In this embodiment, the total length of the cathode carbon block 1 is 3000mm to 4000mm, the width is 400mm to 800mm, and the height is 400mm to 700mm; the bottom of the cathode carbon block 1 has a dovetail groove of equal section, and a dovetail groove of equal section is embedded in the dovetail groove. The bottom cathode steel rod 2 of full length or non-full length, the bottom cathode steel rod 2 is 50mm~90mm wide and 50mm~200mm high, and its material, processing and installation method are the same as those of the traditional cathode steel rod; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com