Composite pipe pile with inner ribs

A composite material and pipe pile technology, which is used in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of interface peeling between pipe piles and pier columns, and achieve the effects of less strength degradation, light weight and flexible design of pier columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

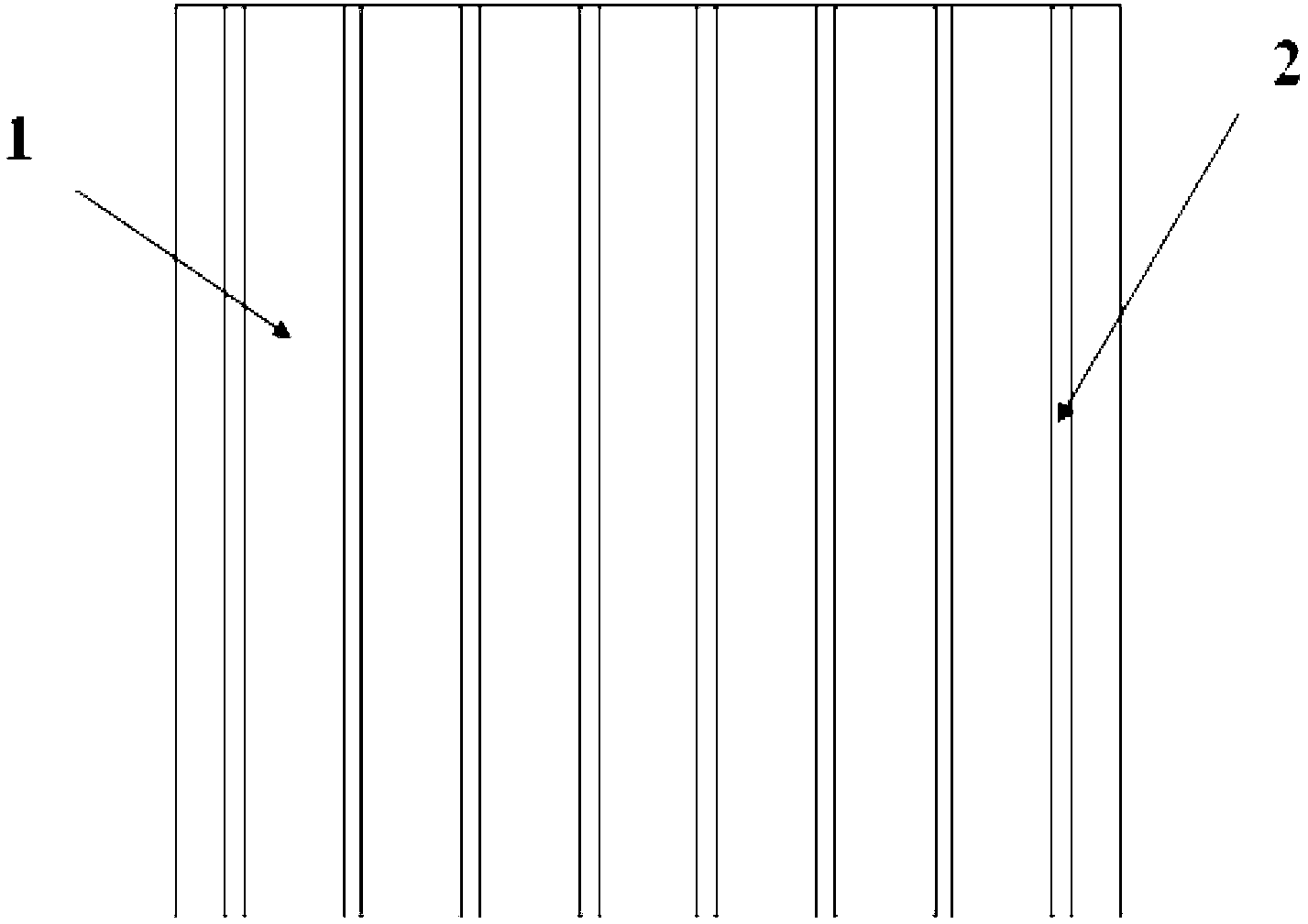

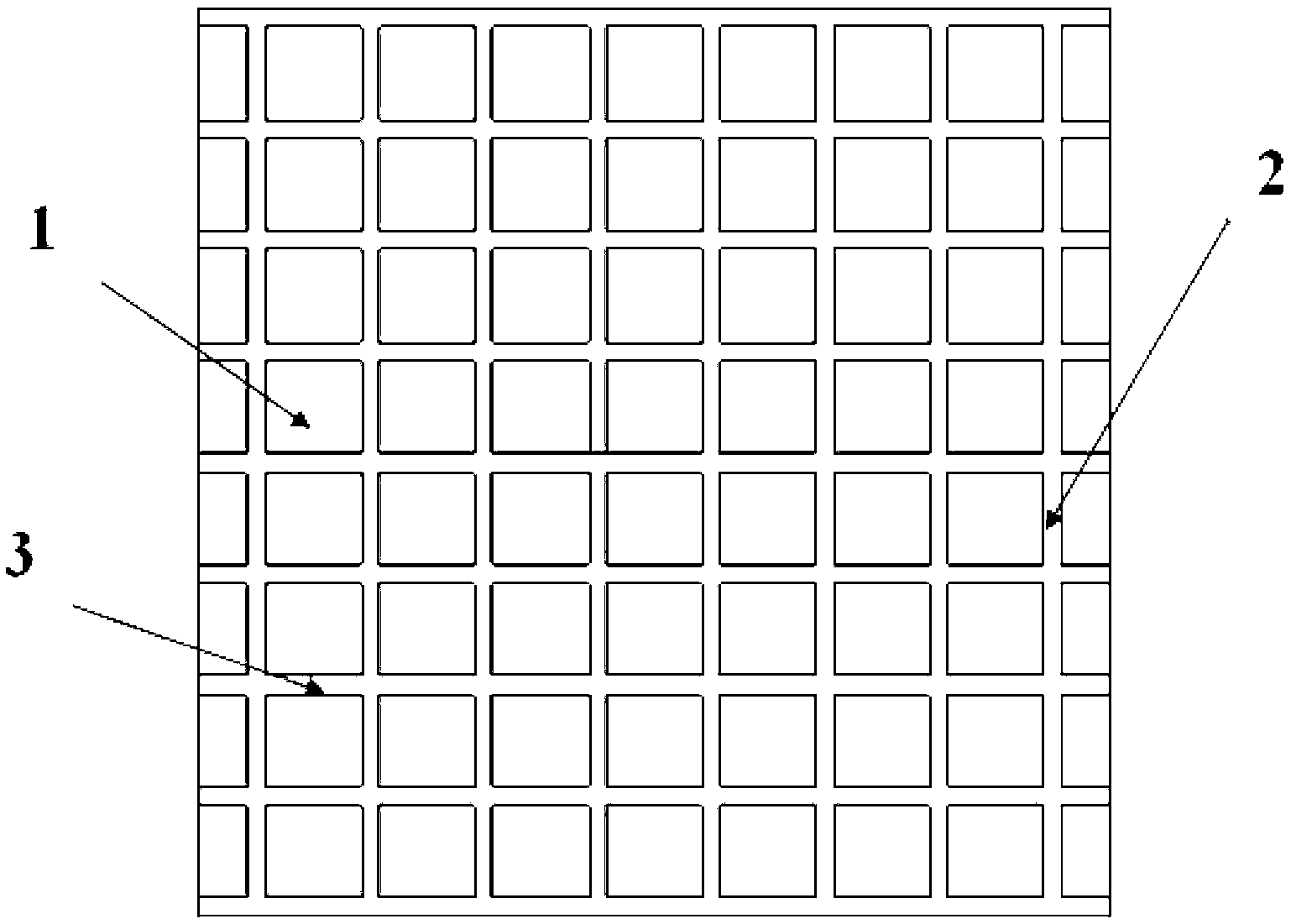

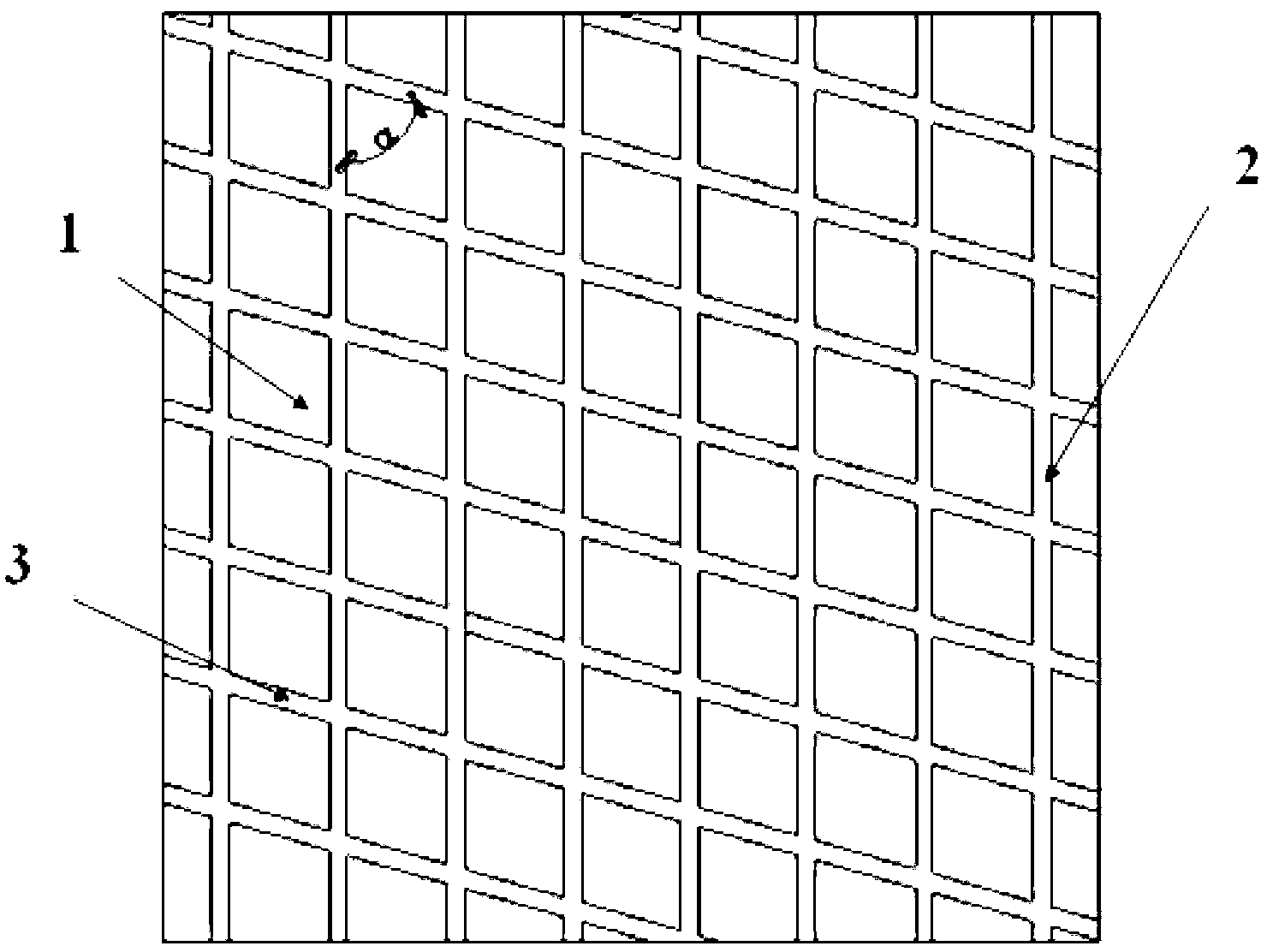

[0034] Such as Figure 1-8 As shown, the present invention forms a rectangular plate 1 with criss-cross ribs on one side through a vacuum introduction process. The width of the rectangular plate 1 is equal to the circumference of the inner wall of the composite material tube to be formed, the length is the same as that of the composite material tube, and the wall thickness of the rectangular plate 1 is No more than 2mm, the longitudinal ribs 2 are generally 4n equally spaced (n=1, 2, 3...), the width is not less than 1cm, the height is not less than 8mm, the distance between the transverse ribs is 10cm-20cm, the width is not less than 3cm, and the height Not less than 3mm;

[0035] The material of the rectangular plate 1 with criss-cross ribs can be a single carbon fiber, glass fiber, basalt fiber or aramid fiber cloth with a vertical and hori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com