Polyurethane-based integrated stretchable supercapacitor and construction method thereof

A technology for supercapacitors and construction methods, which is applied in the field of polyurethane-based integrated stretchable supercapacitors and their construction, and can solve the problem of weak interface between electrodes and electrolytes, restrictions on large-scale applications of electrochemical performance, and unsatisfactory energy density, etc. problem, to achieve the effect of solving the interface bonding problem, excellent resistance to deformation, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

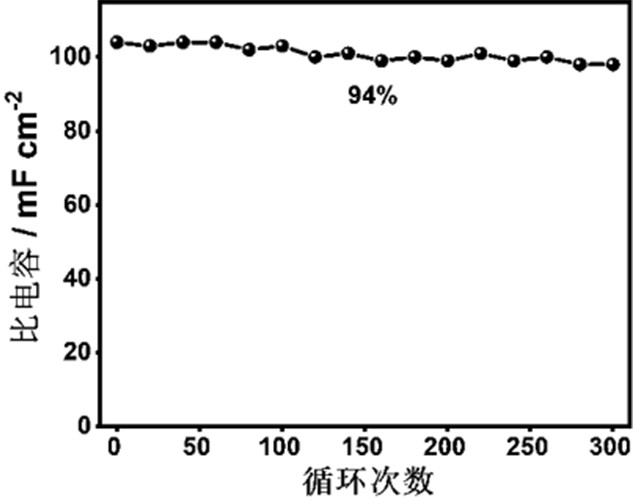

Examples

preparation example Construction

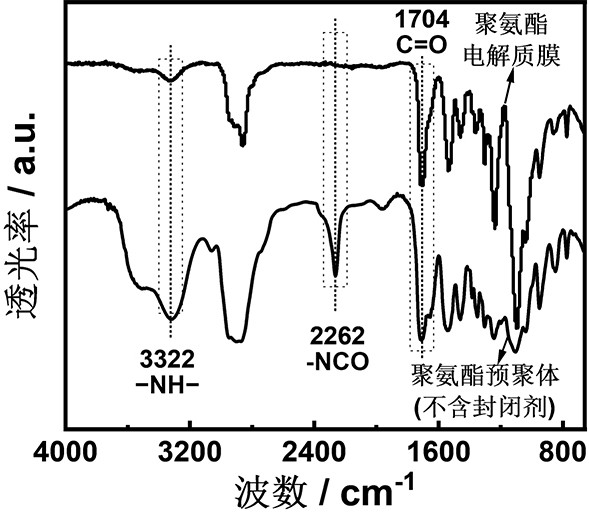

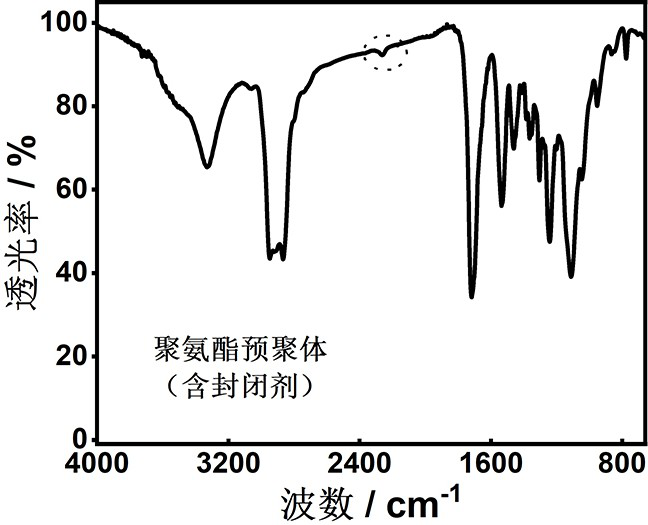

[0039] The preparation of stretchable electrodes based on polyurethane features includes the following steps.

[0040] (1) Add 10.0 g of polyoxyethylene diol with a molecular weight of 1000 into a four-neck round bottom flask, heat to 110°C in an oil bath, and vacuumize for 2 hours to remove water. After cooling down to 90°C, add 5.08 g (0.02 mol) isophorone diisocyanate and 0.78 g (0.003 mol) N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonate sodium chain extender in sequence , control the molar ratio of hydroxyl groups to isocyanate groups in the system to be 1:1.5, rinse the beaker with an appropriate amount of N,N-dimethylacetamide solvent and pour it into it, and pre-polymerize at 90°C for 6 hours in an argon atmosphere to obtain Prepolymer A solution.

[0041] (2) Add conductive carbon black and silver nanowires with a mass ratio of 10:3 as conductive fillers into N,N-dimethylacetamide solvent, and obtain uniform carbon black / silver nanowires after ultrasonic treatment and ...

Embodiment 2

[0054] The preparation of stretchable electrodes based on polyurethane features includes the following steps.

[0055] (1) Add 20.0 g of polyethylene oxide diol with a molecular weight of 2000 into a four-neck round bottom flask, heat to 110°C in an oil bath, and vacuumize for 2 hours to remove water. After cooling down to 90°C, 5.24 g (0.02 mol) of 4,4'-dicyclohexylmethane diisocyanate and 1.46 g (0.005 mol) of dimethyl isophthalate-5-sodium sulfonate chain extender were sequentially added to control The molar ratio of hydroxyl groups to isocyanate groups is 1:1.3, and the beaker is rinsed with an appropriate amount of N,N-dimethylformamide solvent and poured into it, and prepolymerized at 80°C for 6 hours in an argon atmosphere to obtain prepolymer A solution.

[0056] (2) Add conductive carbon black and silver nanowires with a mass ratio of 10:2 as conductive fillers into N,N-dimethylformamide solvent, and obtain uniform carbon black / silver nanowires after ultrasonic treat...

Embodiment 3

[0065] The preparation of stretchable electrodes based on polyurethane features includes the following steps.

[0066] (1) Add 15.0 g of polyoxyethylene diol with a molecular weight of 1500 into a four-neck round bottom flask, heat to 110°C in an oil bath, and vacuumize for 2 hours to remove water. After cooling down to 90°C, add 4.21 g (0.025 mol) hexamethylene diisocyanate and 0.52 g (0.002 mol) N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonate sodium chain extender in sequence , control the molar ratio of hydroxyl groups to isocyanate groups to be 1:2, and rinse the beaker with an appropriate amount of N,N-dimethylacetamide solvent and pour it into it, pre-polymerize at 90°C for 6 hours in an argon atmosphere, and obtain the pre- Polymer A solution.

[0067] (2) Add conductive carbon black and carbon nanotubes with a mass ratio of 10:3 as conductive fillers into N,N-dimethylacetamide solvent, and obtain uniform carbon black / carbon nanotubes after ultrasonic treatment and mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com