Large-sized quick opening-and-closing gate-ball combined valve

A gate valve and ball valve technology, which is applied in the field of large-diameter and fast-opening and closing gate valves and ball valves, can solve the problems of no soft seal, low working pressure of the valve, uneven sealing force of the valve core, etc., so as to achieve easy replacement and work High pressure and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

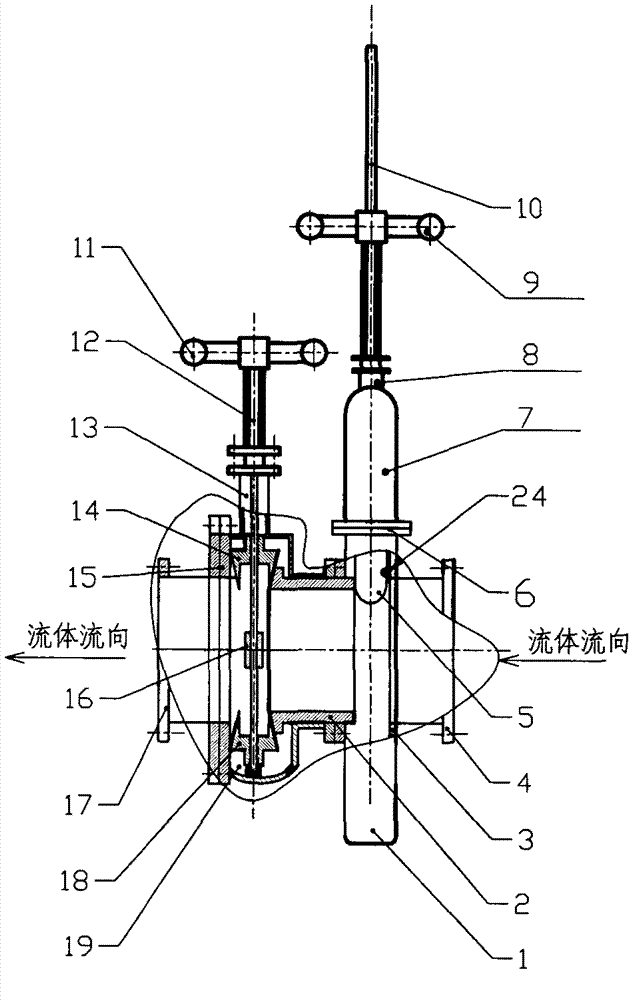

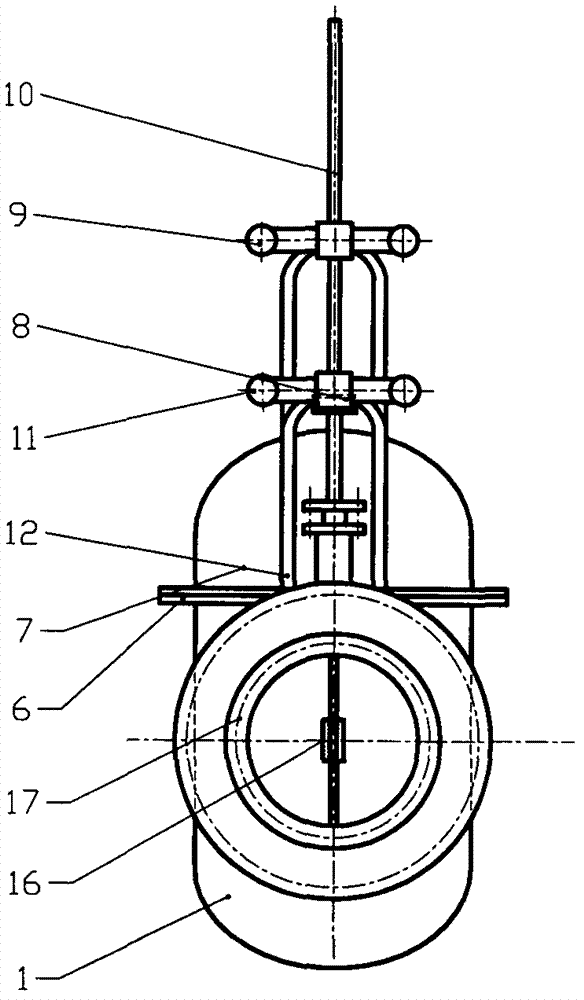

[0021] Embodiment 1 Large-diameter lifting gate valve

[0022] figure 1 It is a front section view of a large diameter lift gate valve, figure 2 yes figure 1 side view. The valve is composed of two parts: the spool chamber and the wedge-shaped slider chamber. The spool chamber is composed of the spool chamber casing (lower part) 1, the spool chamber casing (upper part) 7, the valve seat 3, the inlet flange 4, the gate plate 5, the middle flange 6, the opening and closing upper seal 8, the opening and closing hand Wheel 9, opening and closing valve stem 10 is formed. The wedge-shaped slider chamber is composed of a sealing handwheel 11, a sealing valve stem 12, a sealing upper seal 13, a wedge-shaped slider (upper) 14 and a wedge-shaped slider (lower) 18, a floating pressure ring 2, a fixed pressure ring 15, Coupling sleeve 16, outlet flange 17, wedge-shaped slider chamber shell 19 is made up of.

[0023] Wedge-shaped slide blocks 14 and 18 slide up and down against the ...

Embodiment 2

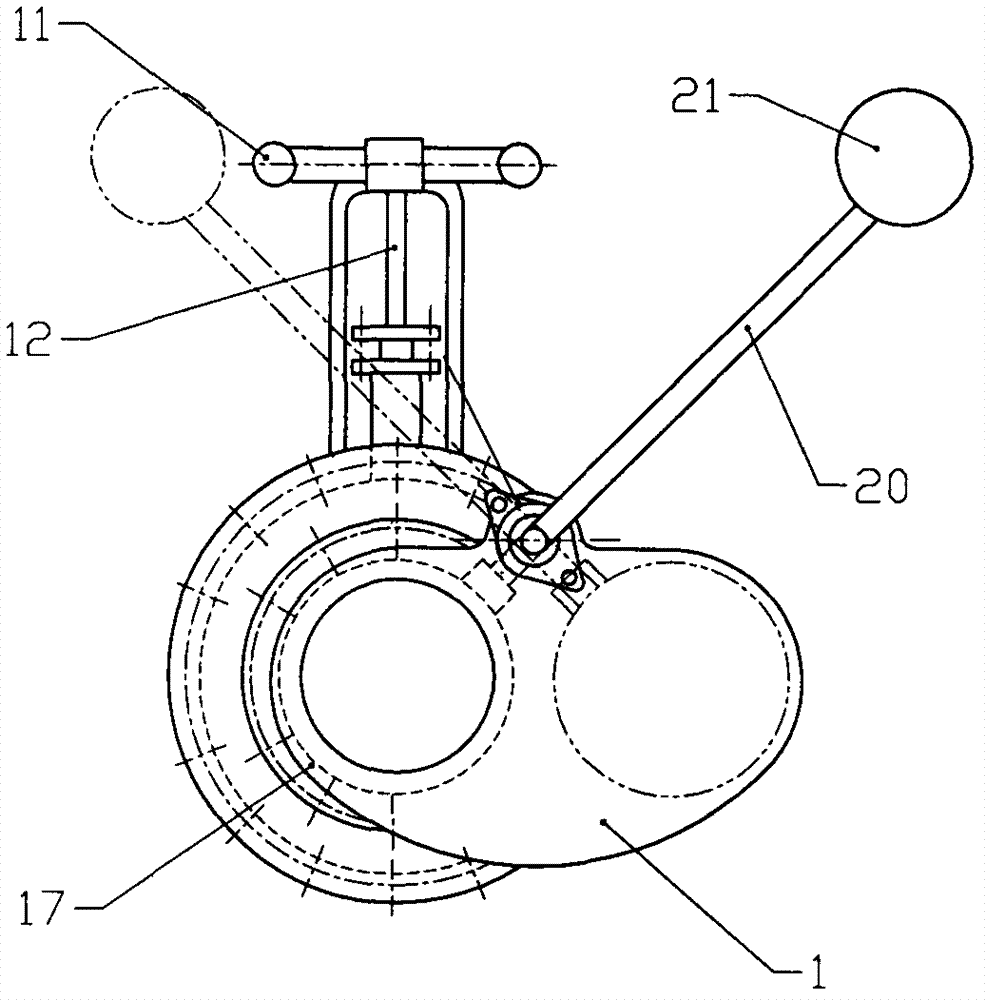

[0027] Embodiment 2 Large diameter swing gate valve

[0028] image 3 is the front view of the large diameter swing gate valve in the closed position, Figure 4 yes image 3 side view. The structure of the wedge slider chamber and figure 1The same, and the shell of the spool chamber is in the shape of a waist, in which the gate can swing left and right. The opening and closing valve stem and the pendulum shaft (not shown in the figure) that drive the gate plate 5 to swing are connected through the opening and closing upper seal 8 and the pendulum handle 20, and are equipped with a counterweight 21 for labor saving and self-locking. Figure 4 The pendulum handle of the middle drawing solid line and the flashboard 5 corresponding to the counterweight are in the closed position, while the dotted line is in the open position.

[0029] Opening of the valve: Turn the sealing hand wheel 11, and through the sealing valve stem 12, the wedge-shaped sliders slide opposite to each ot...

Embodiment 3

[0031] Embodiment 3 large diameter ball valve

[0032] Figure 5 It is the front cross-sectional view of the large-diameter ball valve when it is open. Figure 6 It is the front section view of the large diameter ball valve when it is closed. The structure of the wedge slider chamber and figure 1 The same, and the valve core 22 is spherical, which is different from ordinary ball valves. The valve seat 3 is not a spherical surface but a conical surface, which is more convenient for processing. Same as ordinary ball valves, the top end of the opening and closing valve stem 10 is milled into a square, driven to rotate by a handle (not shown in the figure), and the dynamic sealing is guaranteed by the opening and closing upper seal 8, and the lower end is provided with an anti-blowing structure. Different from ordinary ball valves, when the ball valve is in the closed position, the top of the spherical valve core 22 is provided with a chute, and the spherical valve core 22 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com