Vacuum heat collecting element with hot fin decompression air drying protector

A vacuum heat collector and protector technology, which is applied to solar collectors, solar collectors, and heating devices using working fluids, which can solve the problem of reduced ability to restore the original state, poor pertinence, and bimetal thermal exchange. It can reduce problems such as poor consistency of driving parts, and achieve the effects of reducing outgassing, improving reliability and reducing heat dissipation power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

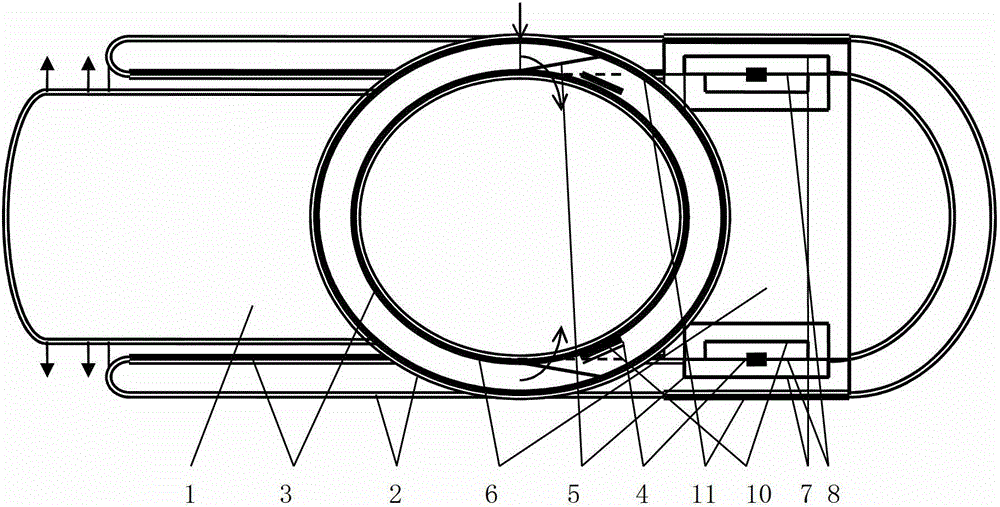

[0031] figure 1 and figure 2 An embodiment of the present invention is collectively given.

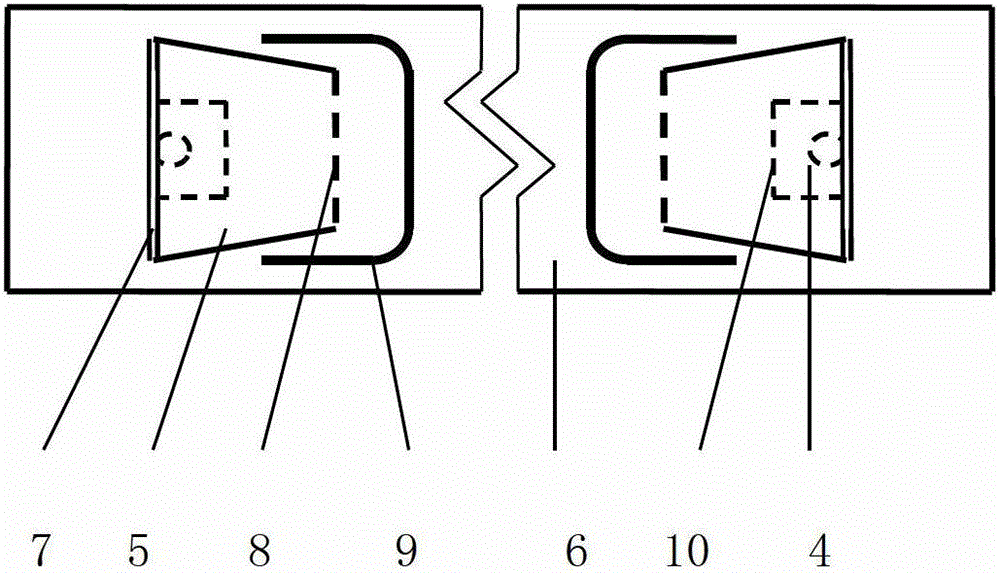

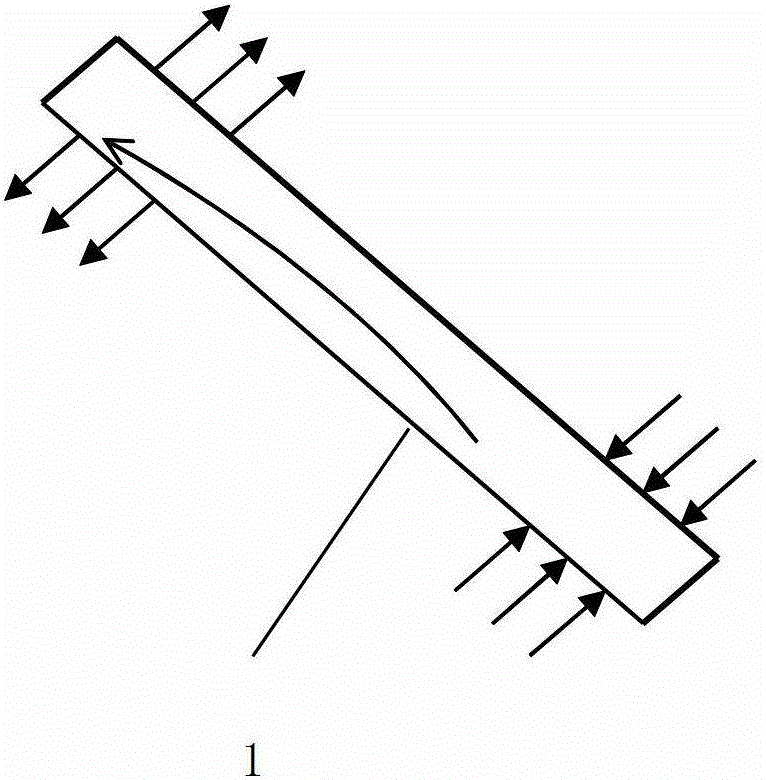

[0032] figure 1 and figure 2 Among them, in the vacuum insulation layer between the end of the cover glass tube and the end of the inner glass tube of an all-glass vacuum heat collecting tube, two thermosensitive permanent magnetic steel 4, soft iron heat fin 5 and connecting card are arranged. The controllable heat transfer channel composed of springs forms a vacuum heat collecting element with a heat fin decompression air drying protector. The soft iron hot fin 5 forms by punching flanging on the heat sink 6, and its movable side 7 is shorter than the fixed side 8. The heat sink 6 is also made with a right-angled connecting clip spring assembly groove 9 to facilitate assembly. The heat sink 6 is rolled into a cylindrical shape with a thin iron plate to wrap the tail end of the inner glass tube 3 with low thermal resistance. The thermosensitive permanent magnet steel 4 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com