Camera mixing calibration method based on quadratic curve and straight lines

A technology of quadratic curves and calibration methods, applied in image analysis, image data processing, instruments, etc., can solve the problems of uncommon templates, troublesome and difficult extraction of straight lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further explained below in conjunction with the accompanying drawings.

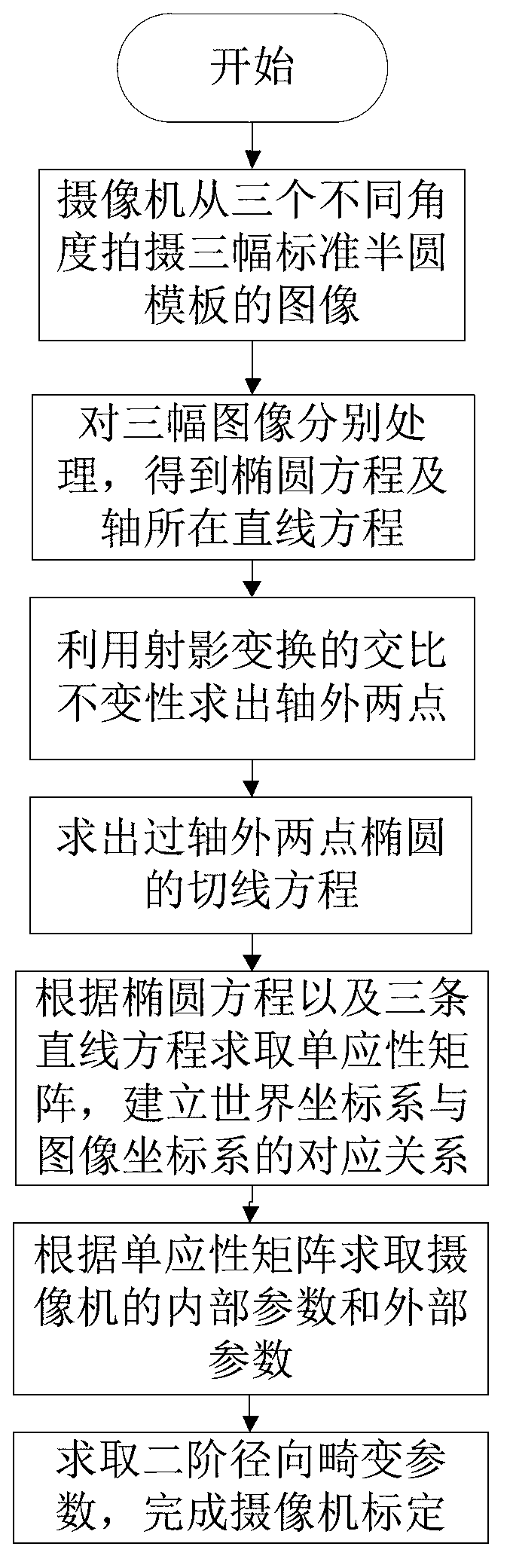

[0082] Such as figure 1 As shown, the specific steps of applying the present invention to realize camera calibration are as follows:

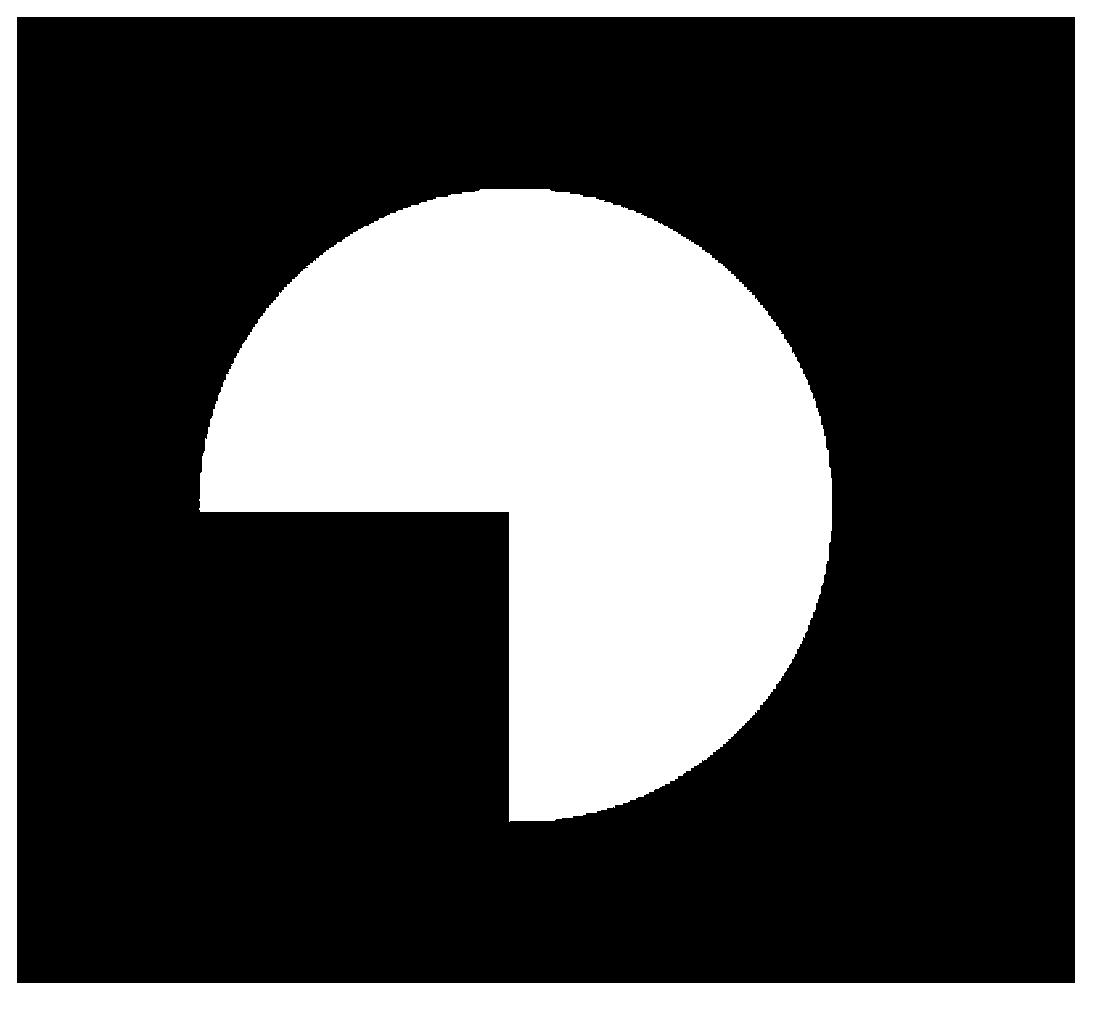

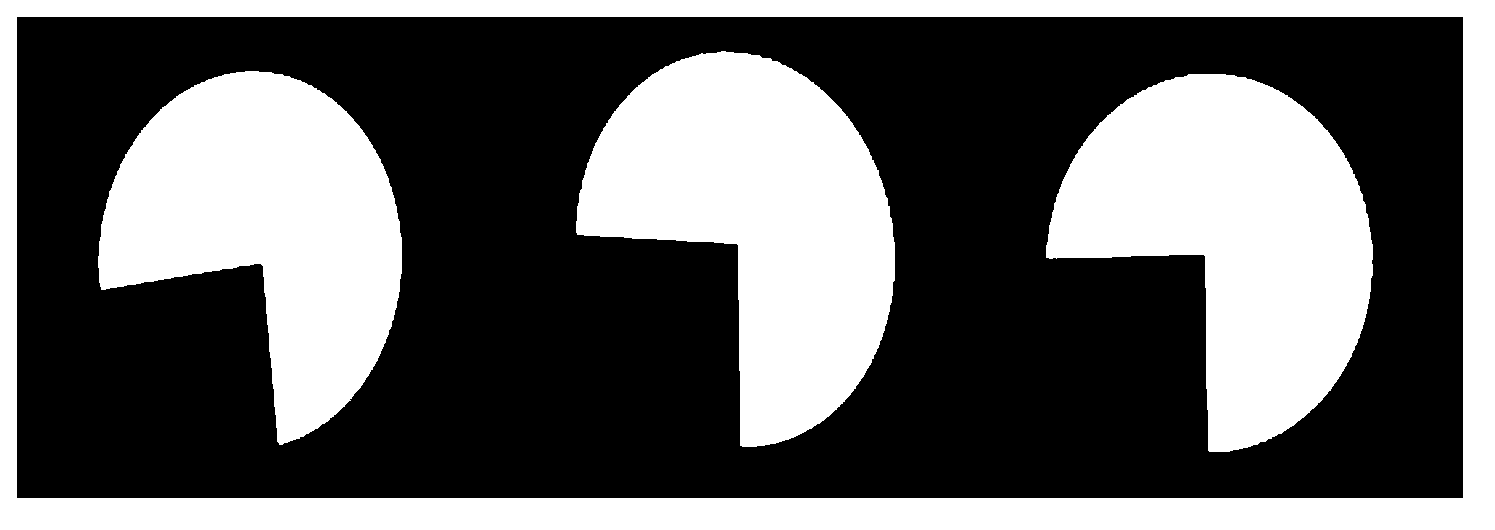

[0083] Step 1: Take the camera from three different angles such as figure 2 standard shown The circular template is photographed and obtained as image 3 The three images shown;

[0084] Step 2: Process one of the images to obtain the 3×3 homography matrix H corresponding to this image:

[0085] Step 2.1: Use the Canny edge detection algorithm to extract the the edge of the ellipse;

[0086] Step 2.2: Fit using the least squares method The equation of the ellipse and the equation of the line on which the two axes of the ellipse lie, such as Figure 4 Shown; Among them, the quadratic equation Q corresponding to the ellipse is:

[0087] Q = a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com