Oil cooling method for data center

A data center and oil cooling technology, applied in the field of data center oil cooling, can solve the problems of high power consumption, serious dust accumulation in ventilation pipes and cooling systems, and large power consumption of central air conditioners, so as to reduce construction costs and improve ambient air quality. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

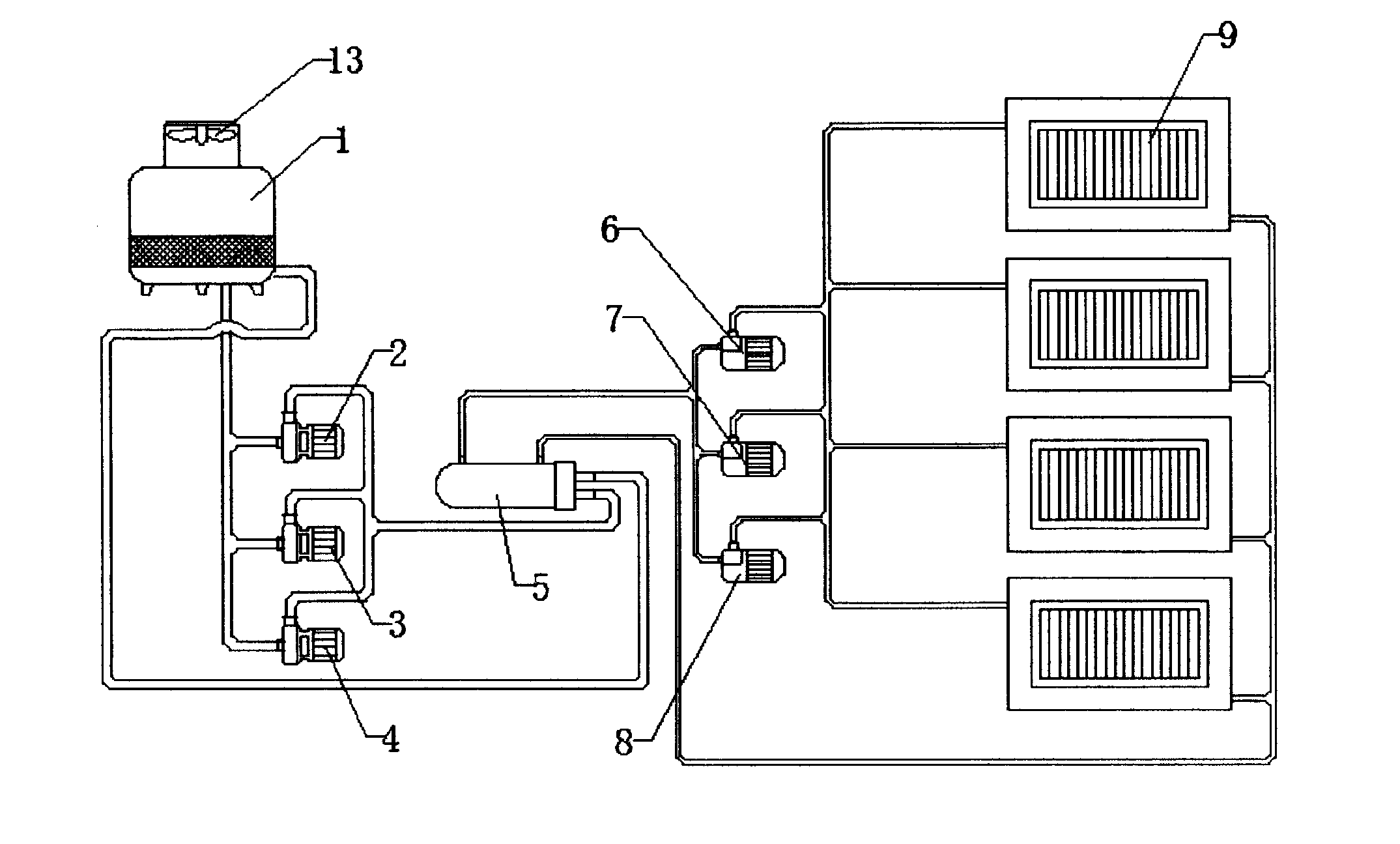

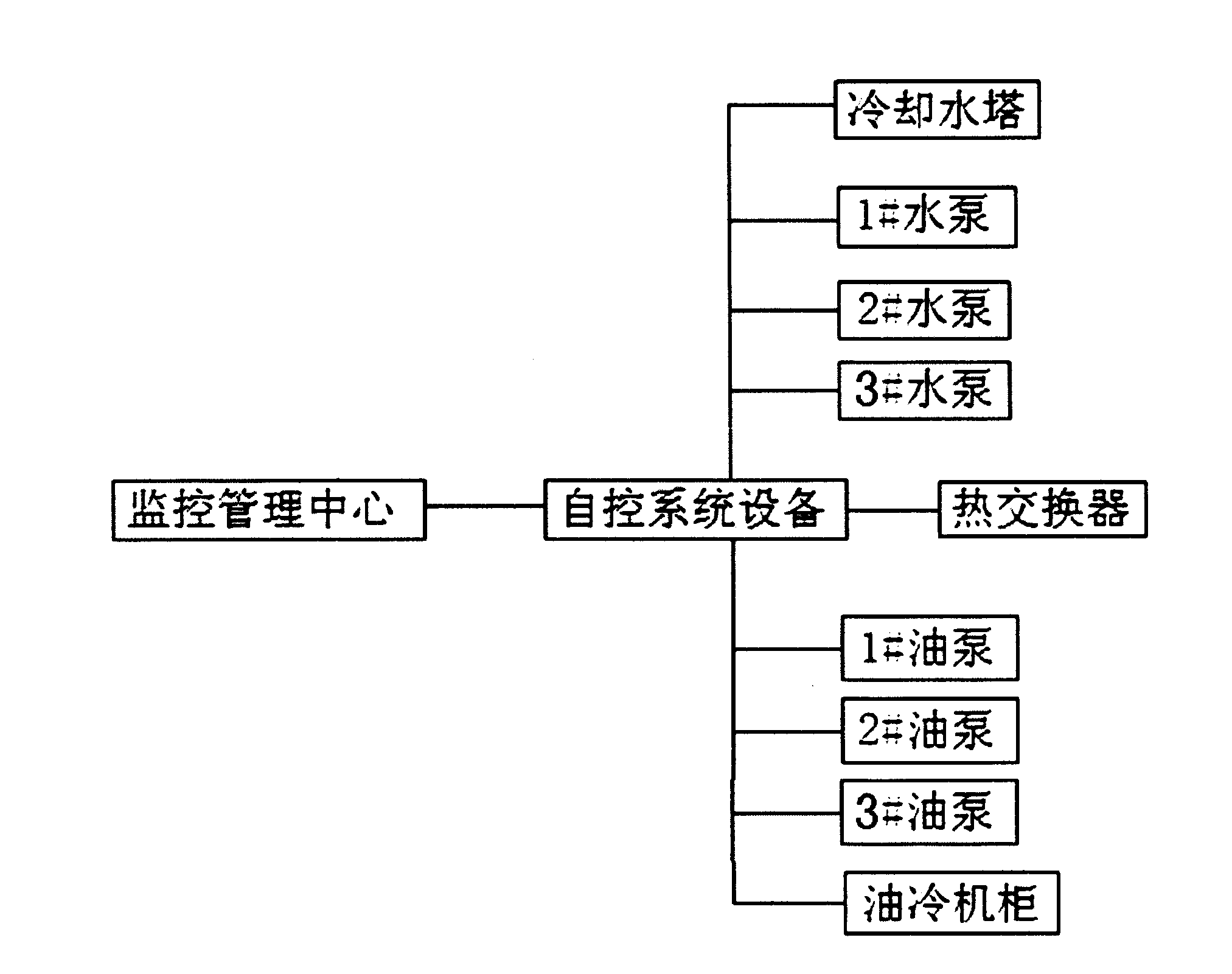

[0038] Such as figure 1 As shown, a data center oil cooling method, the method is to use mineral oil insulation, high thermal conductivity, etc., the server is soaked in mineral oil, the heat emitted by the server during operation is absorbed and transmitted through the mineral oil, and then passed through the oil The cooling and heat dissipation system can be dissipated continuously and efficiently; the oil cooling and heat dissipation system is mainly composed of a cooling water tower 1, a heat exchanger 5, and a number of oil cooling cabinets 9. The bottom of the cooling water tower 1 is connected to 1# water pumps 2 and 2 respectively through water pipes #water pump 3, 3# water pump 4, the water pipes in the water outlet direction of the 1# water pump 2, 2# water pump 3, and 3# water pump 4 are combined into one water pipe to be connected to the water inlet of the heat exchanger 5, in the heat exchange The same side of the water inlet hole of the device 5 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com