Cathode active material for lithium secondary battery, preparation method thereof, and lithium secondary battery using same

A technology for cathode active materials and lithium secondary batteries, which can be used in secondary batteries, lithium batteries, battery electrodes, etc., and can solve problems such as small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

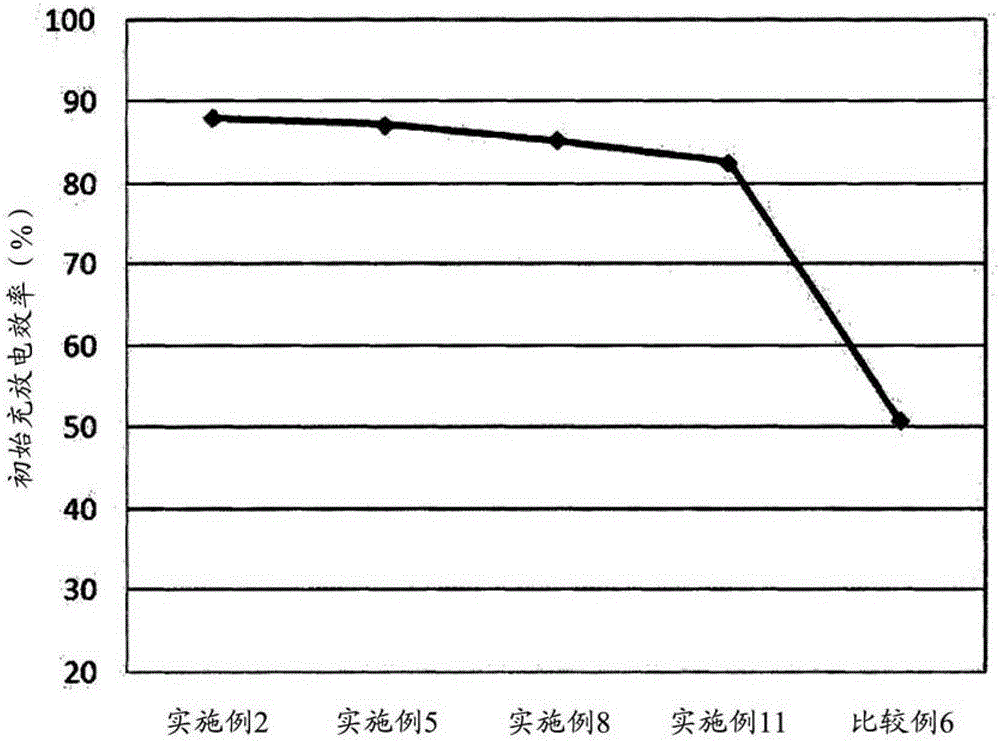

[0078] 7) Preparation method and evaluation of charging and discharging characteristics of test battery

[0079] The detection cell (cell) is a button-type half-cell, which uses an electrode prepared with a cathode active material and a binder at a ratio of 97:3 and a lithium metal foil as a counter electrode, and a separator film is placed between them, As an organic electrolyte solution, an electrolyte solution in which 1M LiPF6 (lithium hexafluorophosphate) was mixed and dissolved with EC / DEC at a ratio of 1:1 was used, and this electrolyte solution was impregnated to prepare a 2016-type coin cell.

[0080] 8) Evaluation of charge and discharge characteristics

[0081] When charging, insert lithium ions into the carbon electrode according to the electrostatic current method at 0.1Crate (charge-discharge rate) until it reaches 0.005V, start from 0.005V, perform lithium ion intercalation according to the electrostatic current method and end lithium ion intercalation when the ...

Embodiment 1

[0085] Synthesis of Polyurethane Resin for Cathode Active Material

[0086] 100 g of a polyol (AKPSSP-104) containing 7 weight percent of hydroxyl groups and 175 g of 4,4'-MDI were stirred at 4000 rpm for 10 seconds to prepare a hardened polyurethane resin. After pulverizing the above-mentioned polyurethane resin with a crusher until the particle size reaches 0.1-2 mm, the temperature of the pulverized product is raised to 700° C. in a nitrogen atmosphere, and the pre-carbonization is carried out at 700° C. for 1 hour to obtain a lithium disulfide with a carbonization yield of 38%. Secondary battery cathode active material precursor. The obtained cathode active material precursor was pulverized by a jet mill until the average particle size reached about 6-12 μm, and the maximum particle size did not exceed 50 μm. The finely pulverized cathode active material precursor is put into a ceramic crucible, heated to 1200°C at a heating rate of 5°C / min in a nitrogen atmosphere, and m...

Embodiment 2

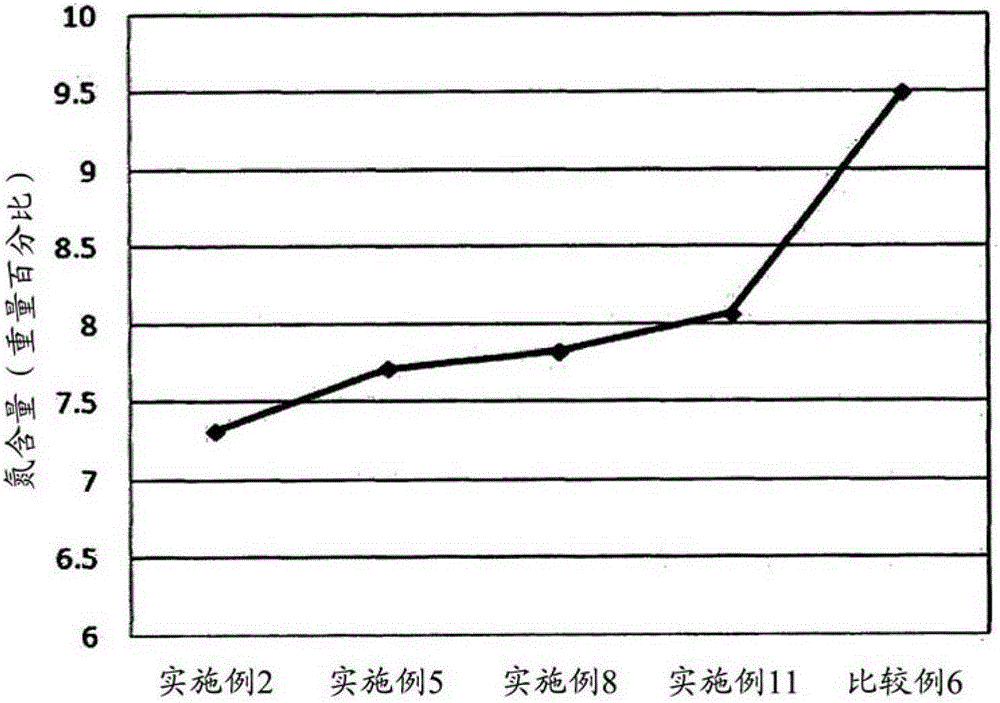

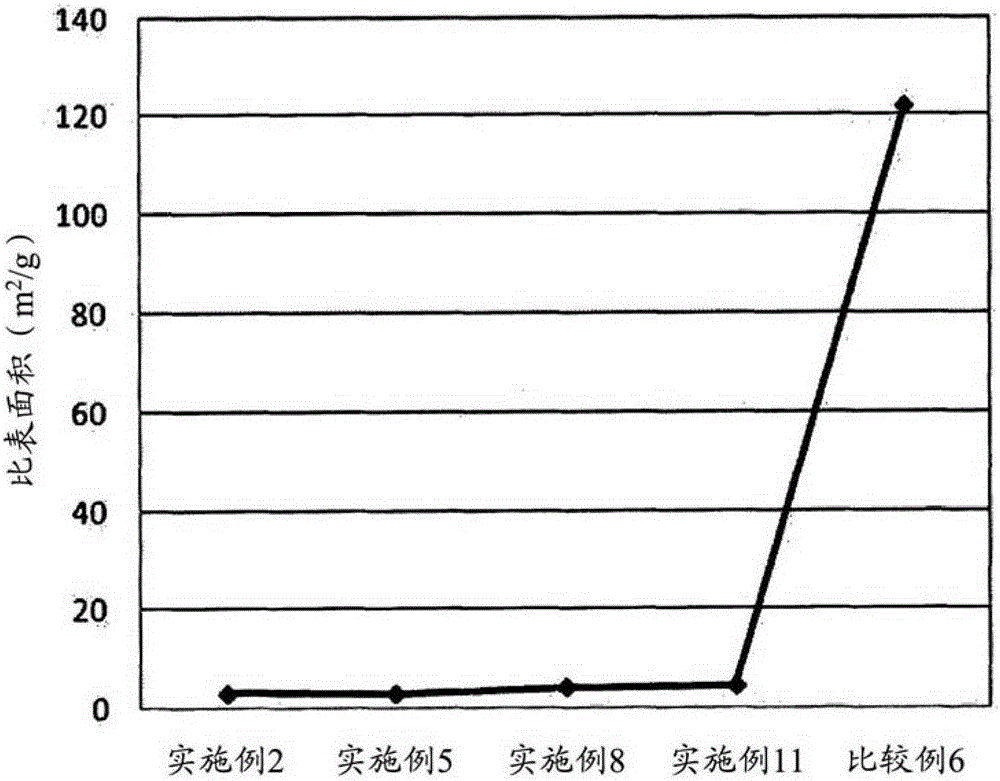

[0088] In Example 2, it implemented similarly to Example 1 except having set the carbonization temperature to 1300 degreeC and implemented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com