Negative electrode for nonaqueous electrolyte secondary battery, manufacturing method thereof, and lithium ion secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve problems such as insufficient maintenance of cycle characteristics, dry and high temperature of electrodes, etc., and achieve high initial charge and discharge efficiency and low volume expansion Excellent efficiency and cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110]

[0111] The average particle size is 5μm, the BET specific surface area is 3.5m 2 / g silicon oxide SiO x (x=1.01) 100g was loaded into a batch heating furnace. Use an oil rotary vacuum pump to reduce the pressure in the furnace, and at the same time raise the temperature in the furnace to 1,000°C. After reaching 1,000°C, let the CH 4 The gas was flowed in, and the carbon coating treatment was performed for 5 hours. In addition, the degree of reduced pressure at this time was 800 Pa. After cooling down, 97.5g of SiO was obtained 2 The Si-dispersed particles are carbon-coated black particles. The obtained black particles have an average particle size of 5.2 μm and a BET specific surface area of 6.5 m 2 / g, electroconductive particles with a carbon coating amount of 5.1% by mass relative to the black particles.

[0112]

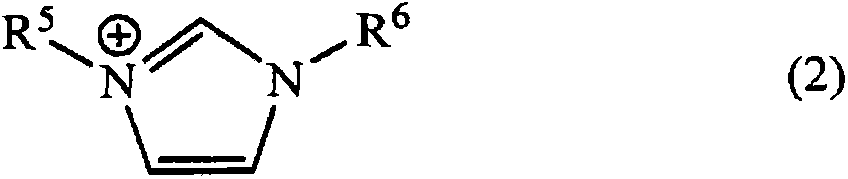

[0113] While flowing nitrogen into a 2L 4-neck flask, 192 g (1.0 mol) of trimellitic anhydride as a polycarboxylic acid anhydride, 132 g (0....

Embodiment 2

[0124] Among 88 parts by mass of conductive particles obtained in Example 1, 0.25 parts by mass of 1.0 parts by mass of 3 μm artificial graphite powder and 0.25 parts by mass of AMC361 (registered trademark) of Ube Industries, Ltd. as fine carbon fibers and 0.75 parts by mass of acetylene black and 10 mass parts of the polyamide-imide resin solution of embodiment 1 are mixed, and then add NMP20 mass parts and make slurry, add the dibutyl glycol solution (bonding agent) as ethylene glycol ether in this slurry 0.2 parts by mass of weight), made into slurry. The slurry is coated on a copper foil with a thickness of 12 μm, and the gap during coating is changed, and it is coated with several thicknesses. After drying at 80° C. for 1 hour, the electrode is pressed and formed by rolling, and the electrode is formed at 200 After vacuum drying at ℃ for 2 hours, punched into 2cm 2 , made into a negative electrode. The electrolyte solution permeability of this negative electrode was co...

Embodiment 3

[0126] Among 88 parts by mass of conductive particles obtained in Example 1, 0.25 parts by mass of 1.0 parts by mass of 3 μm artificial graphite powder and 0.25 parts by mass of AMC361 (registered trademark) of Ube Industries, Ltd. as fine carbon fibers and 0.75 parts by mass of acetylene black and 10 mass parts of polyamide-imide resin solutions of embodiment 1 are mixed, and then add NMP20 mass parts and make slurry, add 12 crown 4 ether powders (0.2 mass of binder weight) as crown ether in this slurry parts) to make a slurry. The slurry is coated on a copper foil with a thickness of 12 μm, and the gap during coating is changed, and it is coated with several thicknesses. After drying at 80° C. for 1 hour, the electrode is pressed and formed by rolling, and the electrode is formed at 200 After vacuum drying at ℃ for 2 hours, punched into 2cm 2 , made into a negative electrode. The electrolyte solution permeability of this negative electrode was confirmed to be 15 seconds. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com