Method for producing nonaqueous secondary battery

A technology of secondary battery and manufacturing method, applied in secondary battery, electrolyte battery manufacturing, non-aqueous electrolyte battery and other directions, can solve the problems of reducing contact area, battery output reduction, contact area reduction, etc., and achieves high initial charge and discharge efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

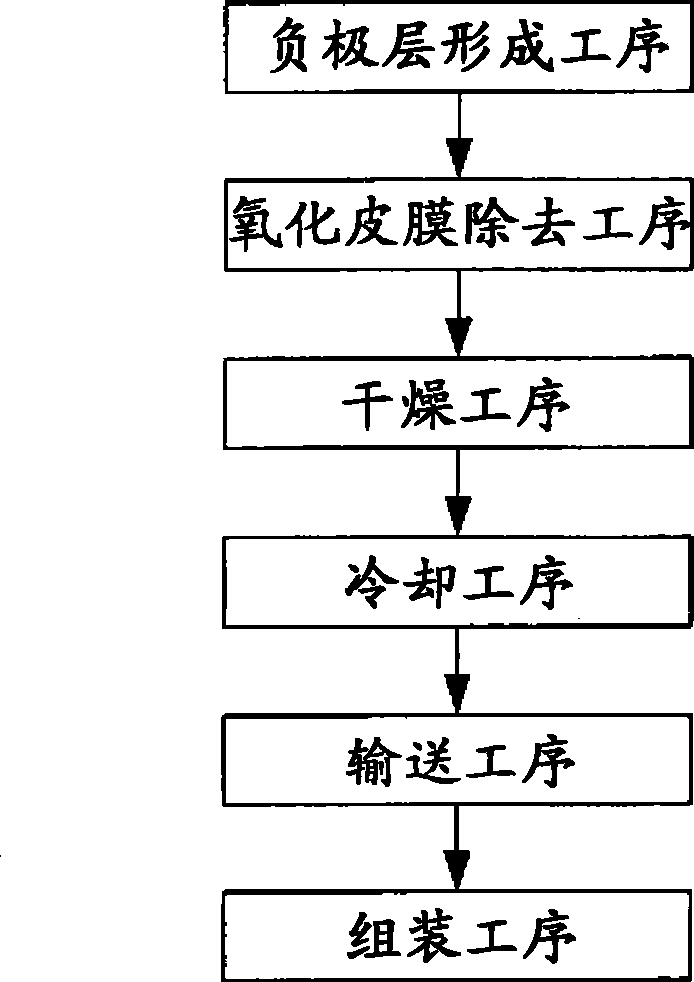

Method used

Image

Examples

Embodiment 1

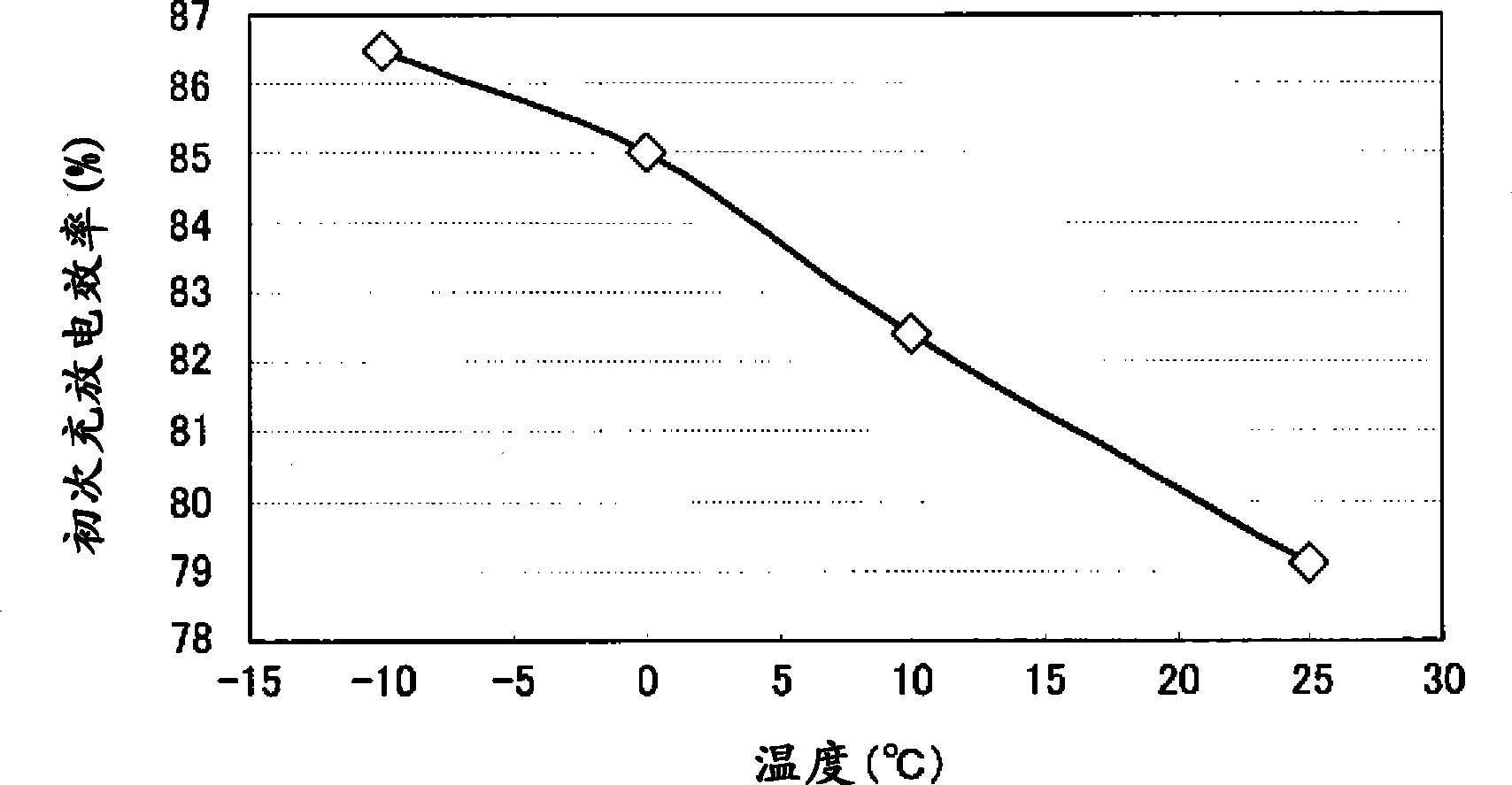

[0061] Prepare a foamed base material made of Ni (surface area 8500m 2 / m 3 , Sumitomo Electric Co., Ltd.), a Sn thin film (film thickness 1 μm) was formed on the foamed substrate by electrolysis to obtain a negative electrode (working electrode). Then, the oxide film on the surface of the Sn thin film was removed by immersing the negative electrode in a 10% by weight aqueous HCl solution for 5 minutes, washed with water, and then dried at 120° C. for 12 hours in an Ar atmosphere. Then, the anode was cooled to 10° C. still under the Ar atmosphere, and thereafter, the anode was transported into a glove box in an Ar atmosphere. Next, lithium metal was prepared as a counter electrode, and a coin-type battery was fabricated as follows while the temperature of the negative electrode was kept substantially constant in the above-mentioned glove box.

[0062] First, the above-mentioned counter electrode was arranged on the bottom surface of the can of the coin-type battery, and a po...

Embodiment 2

[0064] A coin-type battery was obtained in the same manner as in Example 1 except that the cooling temperature of the negative electrode was 0°C.

Embodiment 3

[0066] A coin-type battery was obtained in the same manner as in Example 1 except that the cooling temperature of the negative electrode was -10°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com