Anode material for sodium ion battery, and sodium ion battery

A sodium-ion battery and negative electrode material technology, which is applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems such as the decrease of initial charge and discharge efficiency, and achieve the effect of improving the initial charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

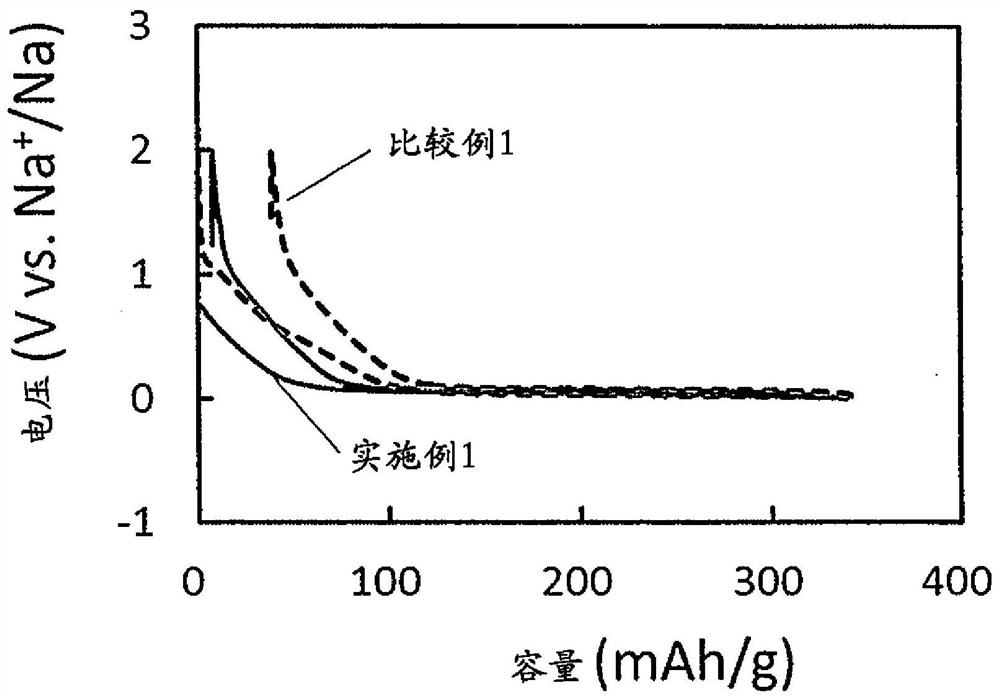

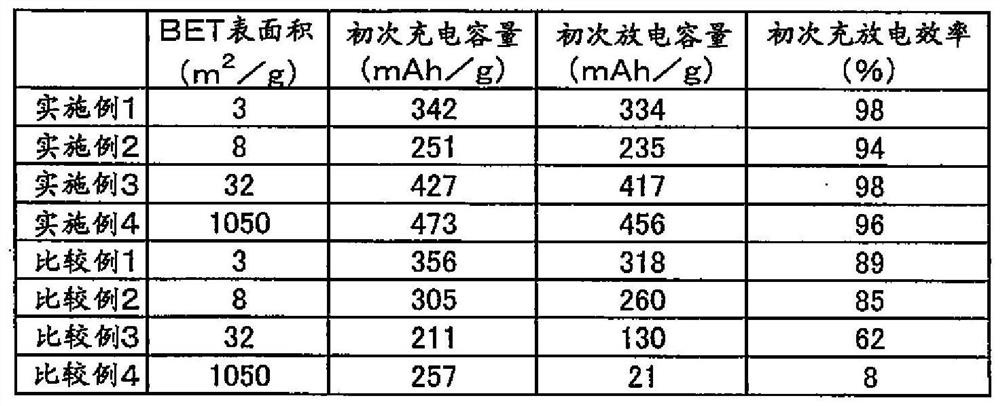

Embodiment 1

[0091] (Synthesis of NaCBH compound)

[0092] NaCB dried overnight at 160°C under vacuum 9 h 10 (manufactured by Katchem Corporation) and NaCB 11 h 12 (manufactured by Katchem Co.) Weigh them in a molar ratio of 7:3, put them in 45 mL of ZrO 2 bottle, and then to ZrO 2 Put 20 pieces of φ5mm Zr into the bottle 2 O balls, mixed at 500 rpm for 20 hours. Thus, a NaCBH compound was obtained.

[0093] (Synthesis of glassy carbon materials)

[0094] 8 mL of 0.01M hydrochloric acid (manufactured by Kishida Chemical Co., Ltd.), 1.2 mL of absolute ethanol (manufactured by Kishida Chemical Co., Ltd.), 4.4 g of resorcinol (manufactured by Sigma-Aldrich Co., Ltd.), and 6 mL of formaldehyde (manufactured by Sigma-Aldrich Co., Ltd. ) were mixed at 0°C, left to stand at 40°C for 24 hours, and dried at 80°C for 24 hours. Then, the operation of adding 60° C. ethanol to the mixture and leaving it still for 4 hours to wash it was repeated three times, and dried at 60° C. overnight. Next...

Embodiment 2

[0100] A sodium-ion battery was produced in the same manner as in Example 1 except that CARBOTRON P (manufactured by Kureha) was used as the glassy carbon material, and a charge-discharge test was performed.

Embodiment 3

[0102] KURARAY COAL YP (manufactured by Kuraray) was fired in an Ar atmosphere at 2000°C for 2 hours to obtain a glassy carbon material, and a sodium-ion battery was produced in the same manner as in Example 1, and a charge-discharge test was performed. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com