Active material, electrode using same, and lithium ion secondary battery

A technology of active materials and secondary batteries, applied in the field of active materials, can solve the problems of low initial charge and discharge efficiency, high irreversible capacity, and reduced battery capacity of positive active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] In Example 1, when making the positive electrode, the lithium-nickel composite oxide (Li-nickel composite oxide (Li 1.01 Ni 0.8 co 0.15 Al 0.05 o 2 ), LiVOPO from the orthorhombic system as the second active material 4 Li obtained by detaching lithium 0.4 VOPO 4 , mixed in a mortar and used as a positive electrode active material.

[0091] [making of positive electrode]

[0092] The active material of Example 1, the conductive additive, and the solvent containing the binder were mixed to prepare a coating material for a positive electrode. The positive electrode coating material was applied to a current collector aluminum foil (20 μm in thickness) by a doctor blade method, dried at 100° C., and rolled. Thus, a positive electrode composed of a positive electrode active material layer and a current collector was obtained. Carbon black (manufactured by NEC, DAB50) and graphite were used as the conductive aid. As a solvent containing a binder, N-methyl-2-pyrrolido...

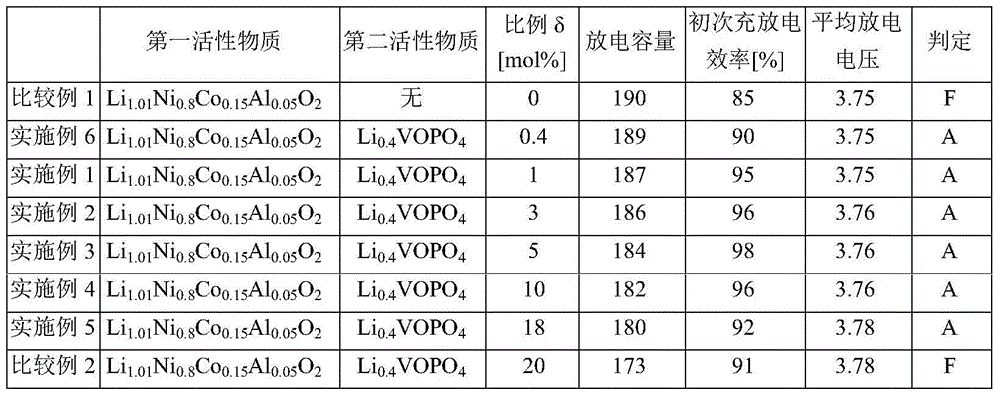

Embodiment 2~6、 comparative example 1、2

[0104] In Examples 2 to 6, Comparative Example 1, and Comparative Example 2, lithium ion secondary batteries were produced in the same manner as in Example 1 except that the ratio δ was changed, and electrical properties were evaluated. The results are shown in Table 1.

[0105] [Table 1]

[0106]

[0107] In Table 1, batteries with a capacity of 180 mAh / g or more and an initial charge-discharge efficiency of 90% or more were evaluated as "A". A battery with a capacity of less than 180 mAh / g or a battery with an initial charge-discharge efficiency of less than 90% was evaluated as "F".

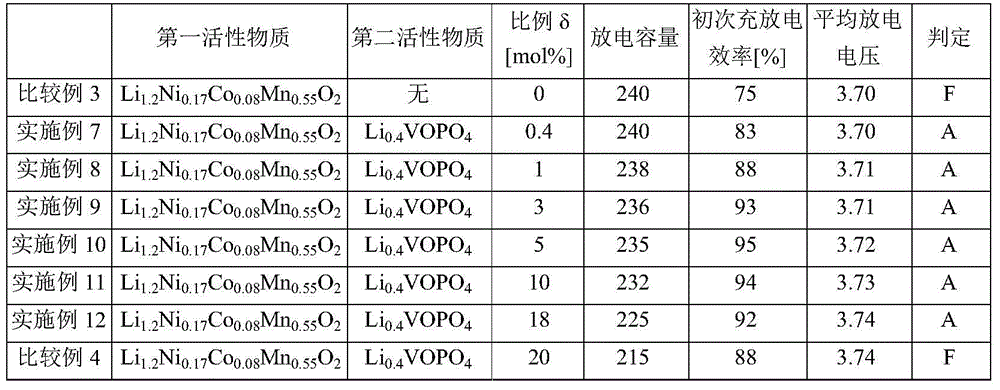

Embodiment 7

[0109] In Example 7, the lithium-nickel composite oxide (Li-nickel composite oxide (Li 1.2 Ni 0.17 co 0.08 mn 0.55 o 2 ), as the second active material, LiVOPO from the orthorhombic LiVOPO 4 Li obtained by breaking away from 0.4 VOPO 4 , mixed in a mortar, and the mixture was used as a positive electrode active material.

[0110] [Determination of electrical properties]

[0111] Next, using the battery of Example 7 produced in the same manner as in Example 1, it was charged at a constant current of 24 mA / g until the end-of-charge voltage became 4.6 V (vs. Li / Li + ), further to 4.6V (vs.Li / Li + ) at a constant voltage until the current value drops to 12mA / g, and measure the initial charging capacity Qc.

[0112] Then, after stopping for 10 minutes, discharge was performed at a constant current of 24 mA / g until the end-of-discharge voltage became 2.0 V (vs. Li / Li + ), measure the initial discharge capacity Qd in the battery.

[0113] The initial charge-discharge effic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com