Walnut kernel coating secondary peeling system and method

A walnut kernel coating technology, which is applied in the field of walnut kernel coating secondary peeling system, can solve the problems affecting the refining process, walnut kernels are wet, etc., and achieve the effect of complete peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

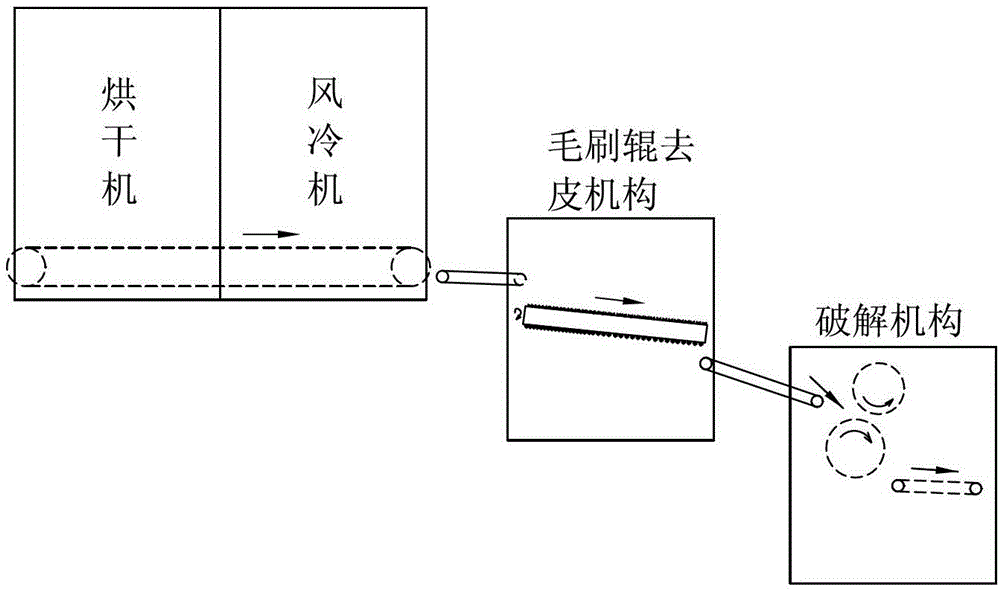

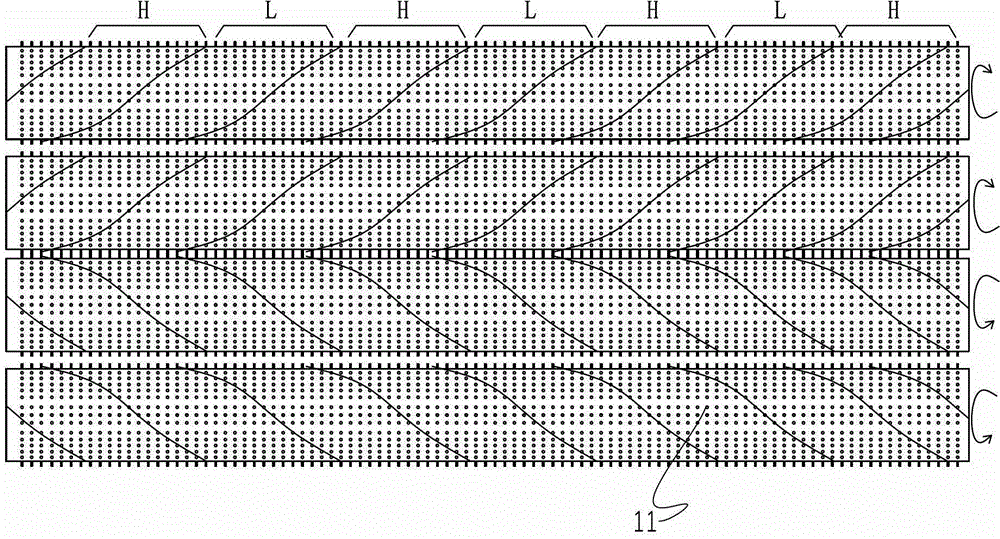

[0033] Such as Figure 1 to Figure 6 , a secondary peeling method for walnut kernel coating, comprising the following steps:

[0034] Drying, using heat radiation to quickly dry the surface of walnut kernels, the heat radiation adopts the existing dryer mode, and uses electric heating to dry it;

[0035] Sharp air cooling, using strong convection to sharply air cool the walnut kernels, and the coating of the walnut kernels becomes crispy, which is beneficial to the subsequent peeling process;

[0036] Brush peeling, the surface coating of walnut kernels is removed by brush removal, the exposed coating on the surface of walnut kernels is removed, and the coating on the surface layer is removed with a brush, because the dried walnut kernels and coating Detachment has occurred, and the peeling effect is more obvious, and most of the coating on the surface can be removed;

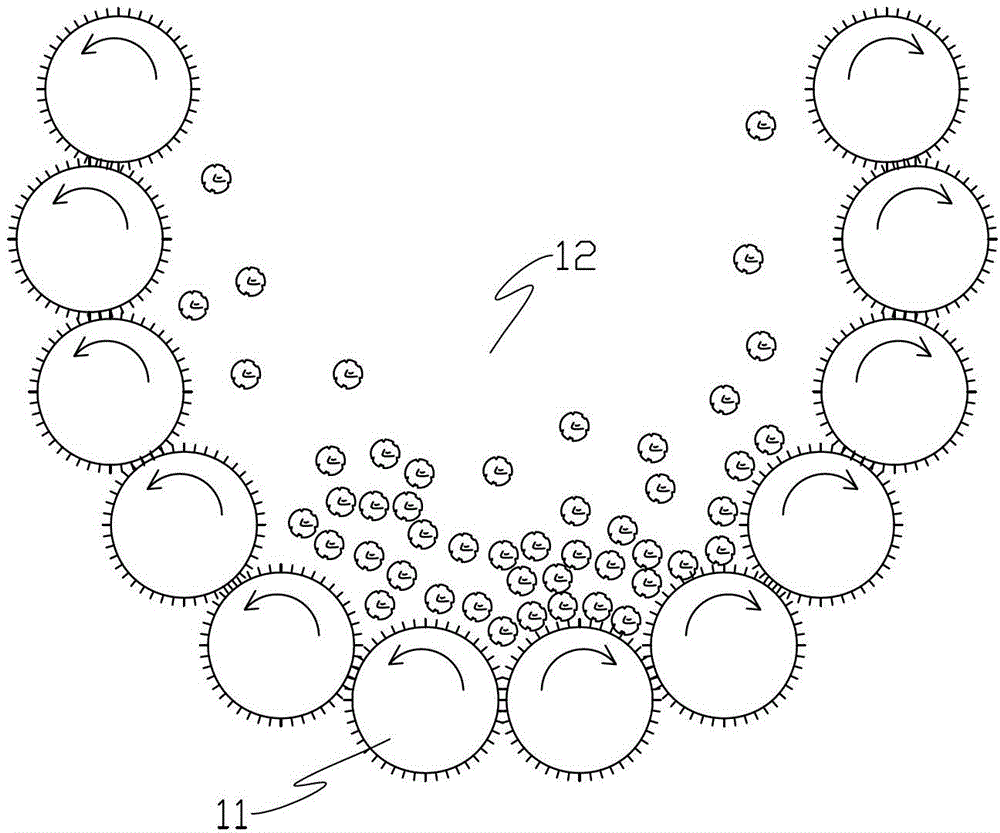

[0037] Cracking, using rollers to grind the walnut kernels to crack the whole walnut kernels into small pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com