Preparation method of perfuming filter stick with perfumed substance released slowly

A technology of aroma substances and filter sticks, which is applied in the field of preparation of scented filter sticks with sustained release of aroma substances, which can solve the problems of uneven release of aroma substances, easy volatilization of aroma substances, low requirements for aroma components, etc., and achieve the effect of aromatization Significant, low requirement for fragrance substances, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

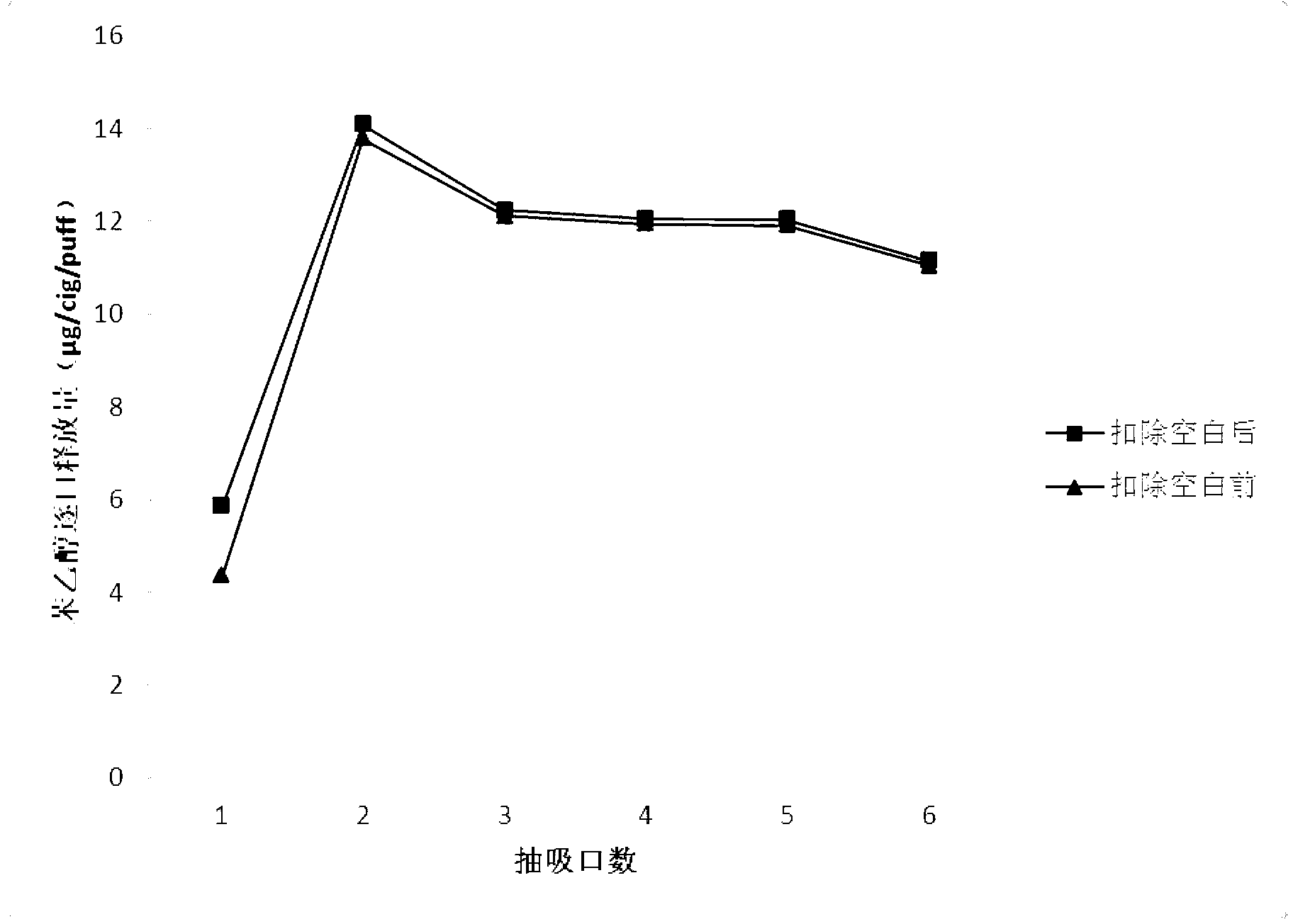

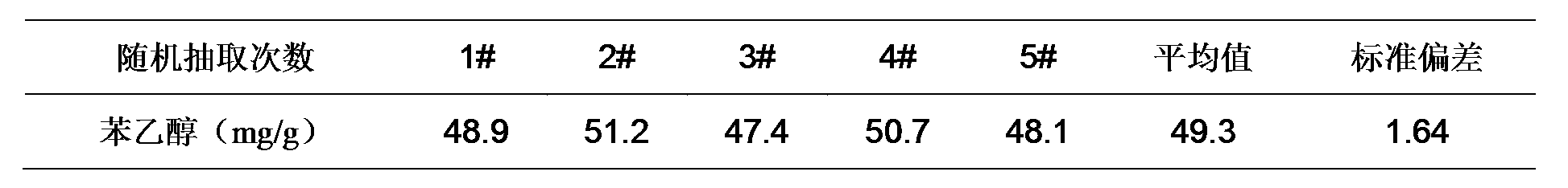

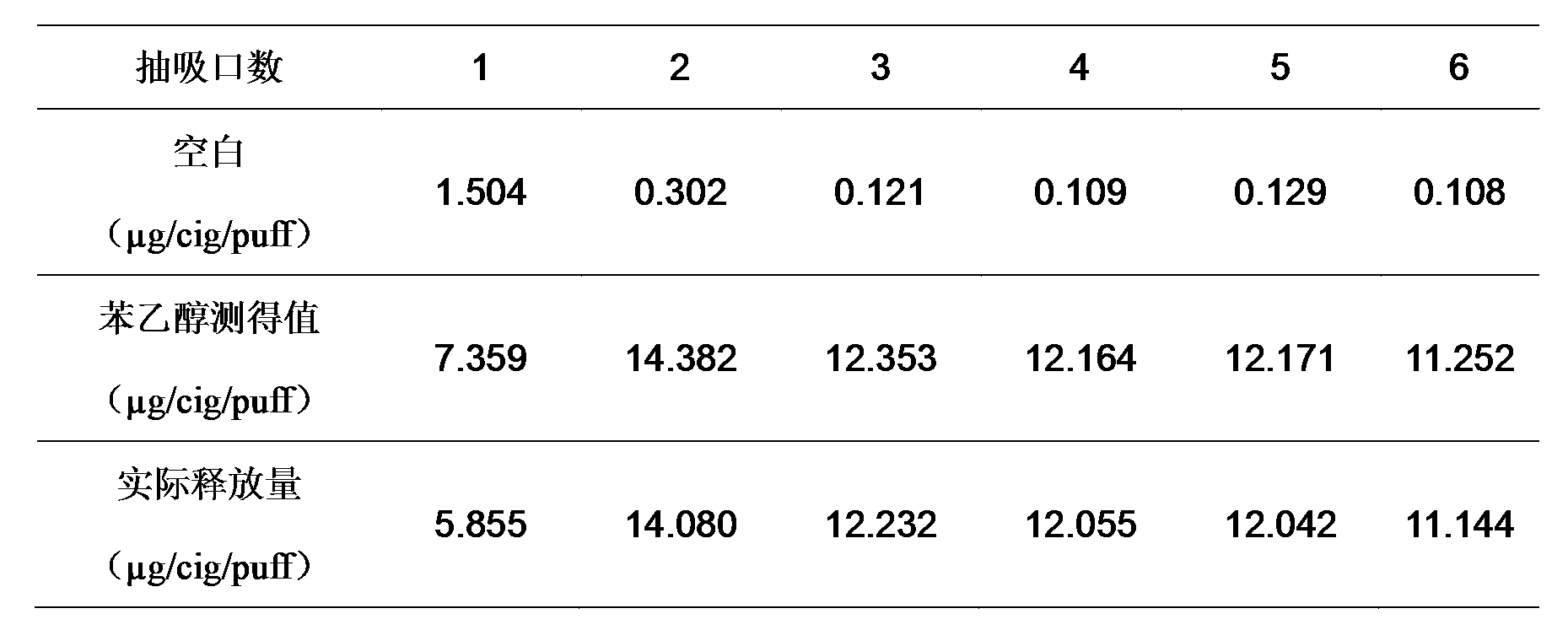

[0016] Embodiment 1: In the laboratory, using phenylethyl alcohol as a marker, measure its dispersion and release in the polyethylene glycol system, and the polyethylene glycol with molecular weight of 4000-6000 is in the range of 60-80 o C heated until completely melted, cooled to 50-55 o C, add phenylethyl alcohol and polar / non-polar block polymer functional nano-dispersion aids (20% of the total amount) according to 20% by mass, stir thoroughly for 10-20min, then cool to solid state. at -10-25 o C crush into granules in frozen state, sieve, and take granules between 40-60 mesh. Add the obtained polyethylene glycol flavoring granules to cellulose acetate filter sticks at a rate of 400 mg / piece to make binary composite filter sticks, and then machine-roll them to make cigarettes. Take 1g of polyethylene glycol particles containing phenylethyl alcohol and place it in a 250mL ground-mouth Erlenmeyer flask, in a water bath of 60 o C until completely melted, add 50ml of t...

Embodiment 2

[0030] Embodiment 2: This embodiment is the same as embodiment 1, and the difference is that phenethyl alcohol and polar / nonpolar block polymer functional nanodispersion are added in the polyethylene glycol that melts completely As an auxiliary agent, add polyethylene glycol particles containing phenylethyl alcohol to the cellulose acetate filter stick at a rate of 40 mg / piece, and the rest of the steps are the same.

Embodiment 3

[0031] Embodiment 3: This embodiment is the same as embodiment 1, the difference is that in the completely melted polyethylene glycol, add phenylethyl alcohol and polar / non-polar block polymer functional nano-dispersion by 10% by mass Auxiliary, add 100mg / piece of polyethylene glycol liquid containing phenylethanol to the cellulose acetate filter stick, specifically: form a thin stream through the pores, flow into the cellulose acetate filter stick, and after the filter stick solidifies, it can form A thread-like polyethylene glycol scented thread, made into a scented slow-release filter stick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com