Assembly technology of split type medical intravenous needle

An assembly process, a technology for intravenous needles, applied in the field of medical devices, can solve the problem that the amount of glue applied to the infusion needle and the seat body is not easy to detect and control, the direction of the infusion needle edge face slope is difficult to control, and the positioning and transportation of raw materials for the dual-blade needle seat Inconvenience and other problems, to achieve the effect of saving process, reducing scrap rate and smooth puncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

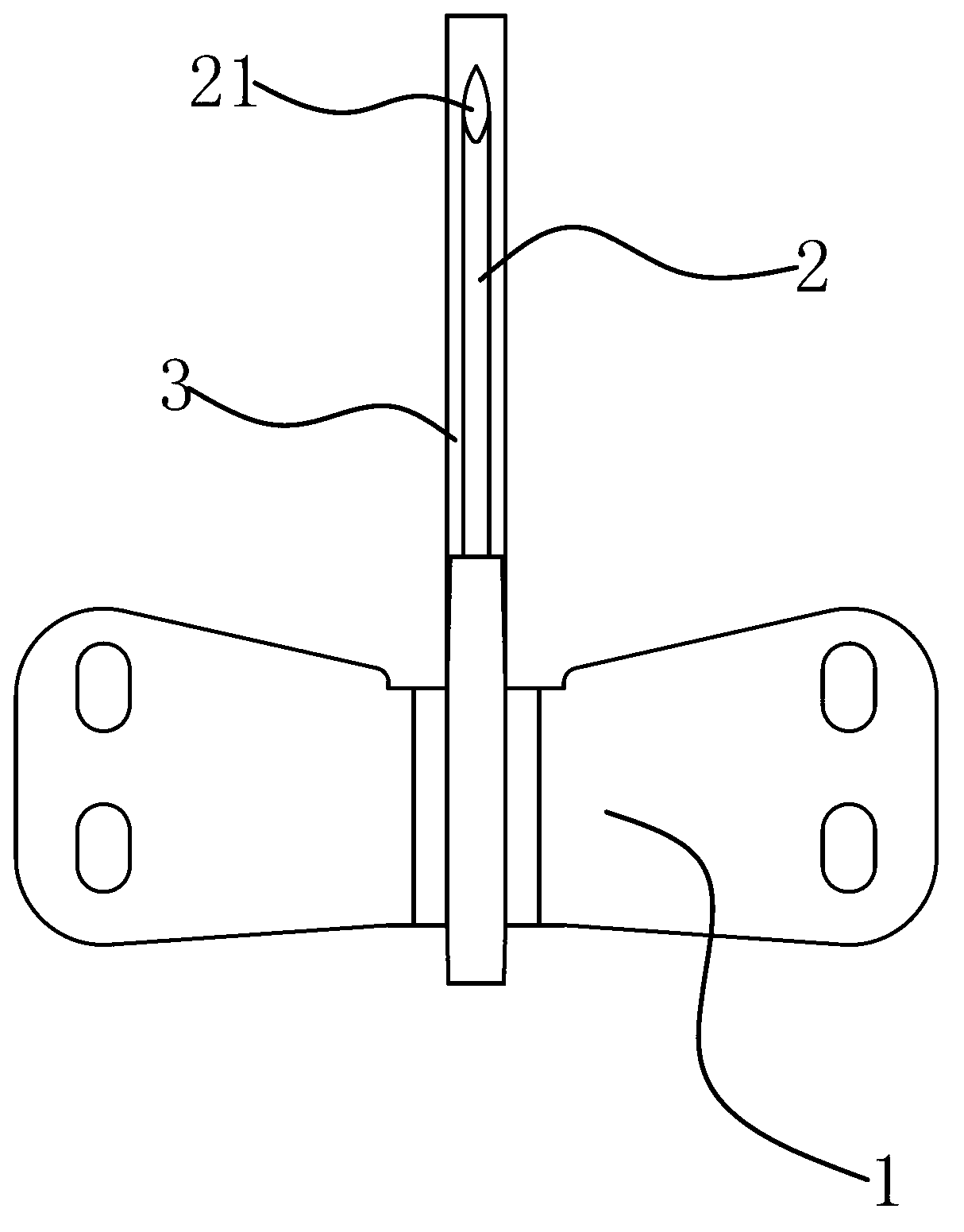

[0054] Such as figure 2 As shown, the venous needle includes a double-leaf needle holder 1 , a steel needle 2 and a protective sheath 3 .

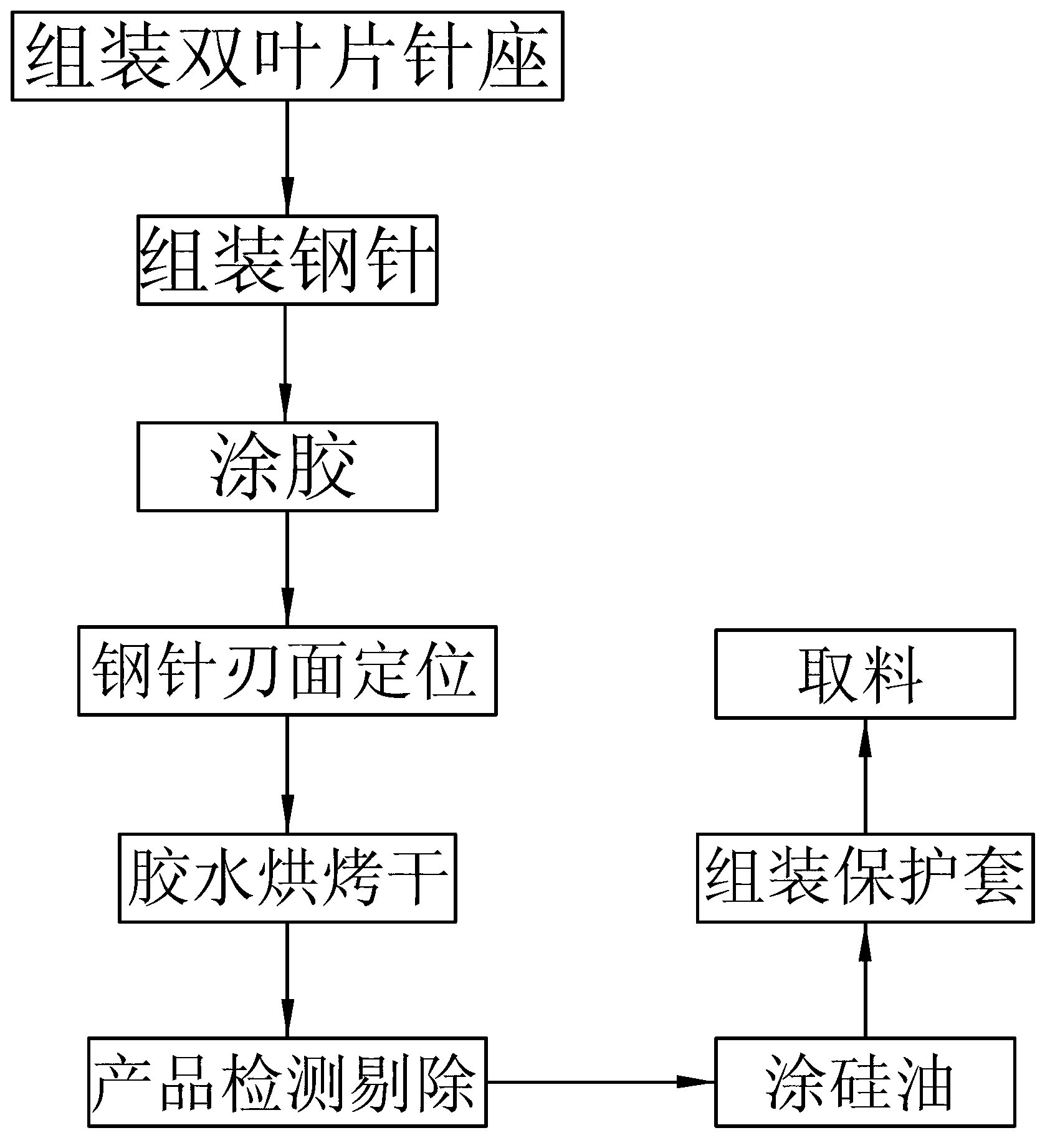

[0055] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the assembly process includes the following steps:

[0056] A. Assembling the double-leaf needle seat: place the blade part 11 in the feeding mechanism 1, place the needle tube part 12 in the feeding mechanism 2, place the tooling tool in the lower part of the feeding device, and pass it through the feeding device 1. The function is to load the blade parts 11 sequentially and orderly on the tool carrier for positioning; the needle tube part 12 is taken out from the feeding mechanism 2 by the assembly manipulator and sent to the gluing mechanism for gluing, and then the needle tube part 12 is assembled by the assembly manipulator. Assemble with the blade part 11 on the tool carrier, and then dry the glue to fix the above two to form the double-blade needle holder 1...

Embodiment 2

[0082] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, process D also includes the second automatic correction step of the steel needle blade surface: the tool carrier is transported through the transmission belt Go to the second place of the CCD industrial camera, take pictures of each steel needle 2 on the tool carrier through the second CCD industrial camera, and transmit the image data to the intelligent identification system, and identify the position of the steel needle blade surface 21 through the intelligent identification system And compare it with the standard blade surface 21 position set by the system, so as to calculate the phase difference angle between the two and convert it into a servo signal, and perform secondary rotation correction on the unqualified steel needle 2 through the servo motor. Through the automatic secondary correction, the labor production effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com