Long-stroke two-dimensional nano worktable system with angle compensation function

An angle compensation, two-dimensional nanotechnology, applied in the direction of worktables, manufacturing tools, etc., can solve problems such as difficult to realize, difficult to compensate, and high cost, and achieve the effects of large range of motion, high positioning accuracy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

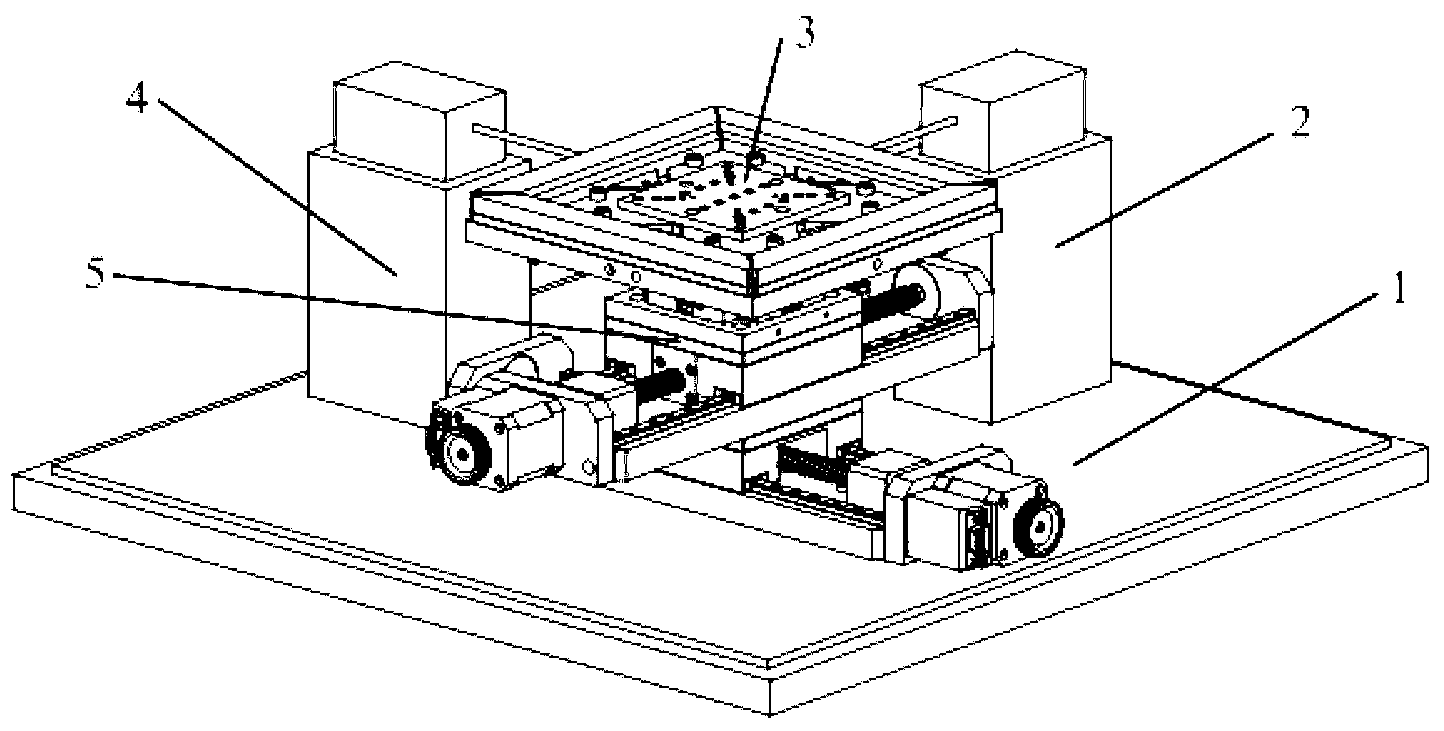

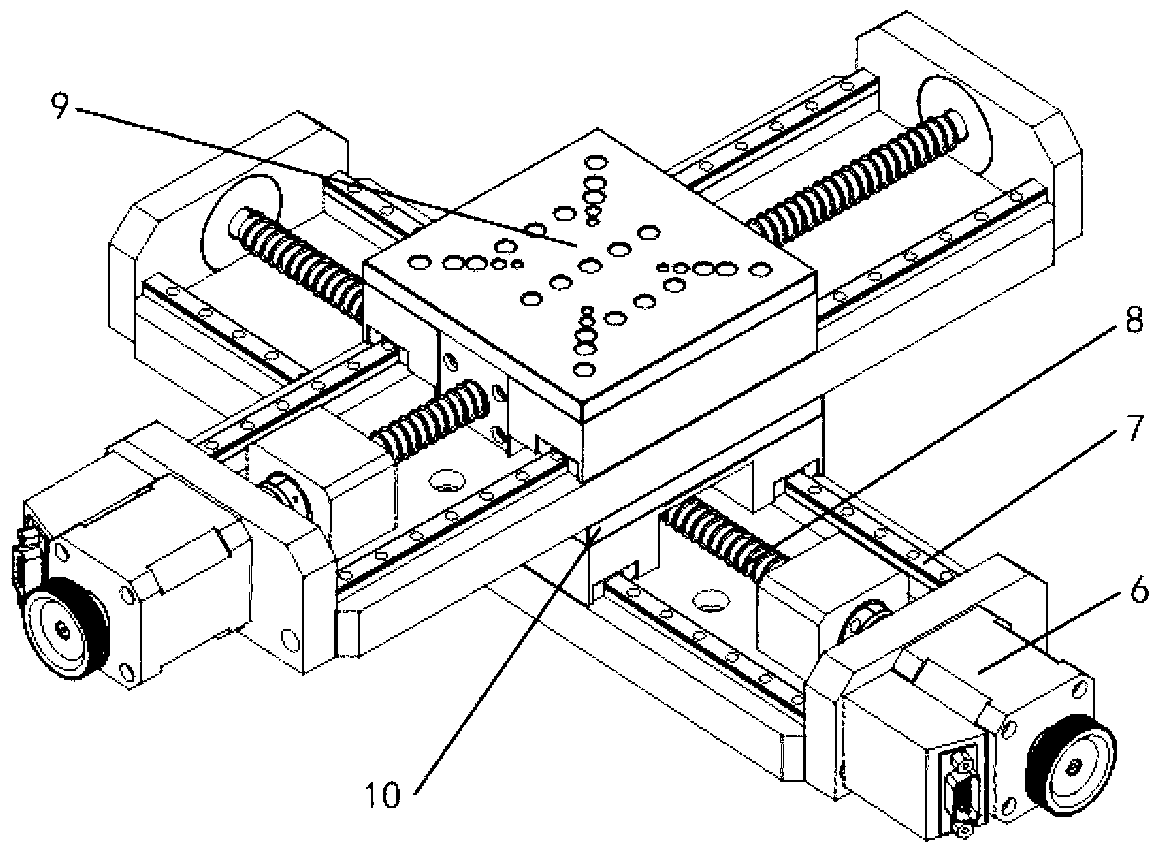

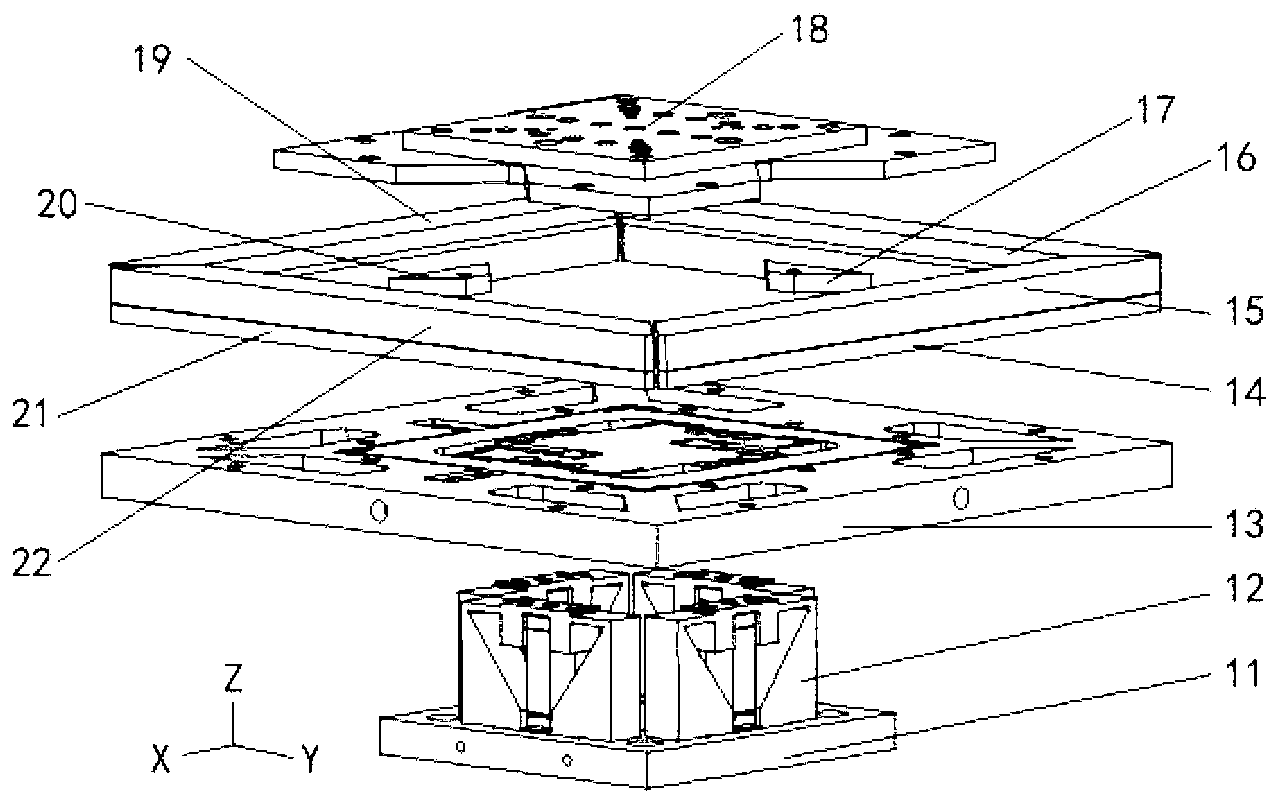

[0021] see figure 1 , figure 2 , image 3 , the present invention comprises a base 1, a large-stroke two-dimensional workbench 5, a six-degree-of-freedom micro-motion workbench 3, and two sets of optical length-measuring and angle-measuring systems 2 and 4 arranged at an angle of 90 degrees; in order to make the workbench The linear positioning accuracy of the X and Y axes of the positioning system reaches the nanometer level, and the linear motion of the six-degree-of-freedom micro-motion table 3 is used to compensate the linear positioning error of the two-dimensional table 5 with a large stroke. The angle error is compensated for the angle error of the large-stroke two-dimensional worktable 5 through the angular movement of the six-degree-of-freedom micro-motion table 3;

[0022] The large-stroke two-dimensional workbench 5 is composed of two sets of single-axis workbenches arranged along the X direction and the Y direction, which are superimposed up and down. Each singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com