Thermal tempering production method and equipment for thin glass

A technology of thin glass and equipment, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as hindering the radiation heat transfer between the heater and glass, affecting the precise and uniform heating of glass, temperature fluctuation and reaction lag, etc. Achieve the effect of reducing shielding effect, ensuring stable radiation heating, overcoming temperature fluctuation and reaction hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

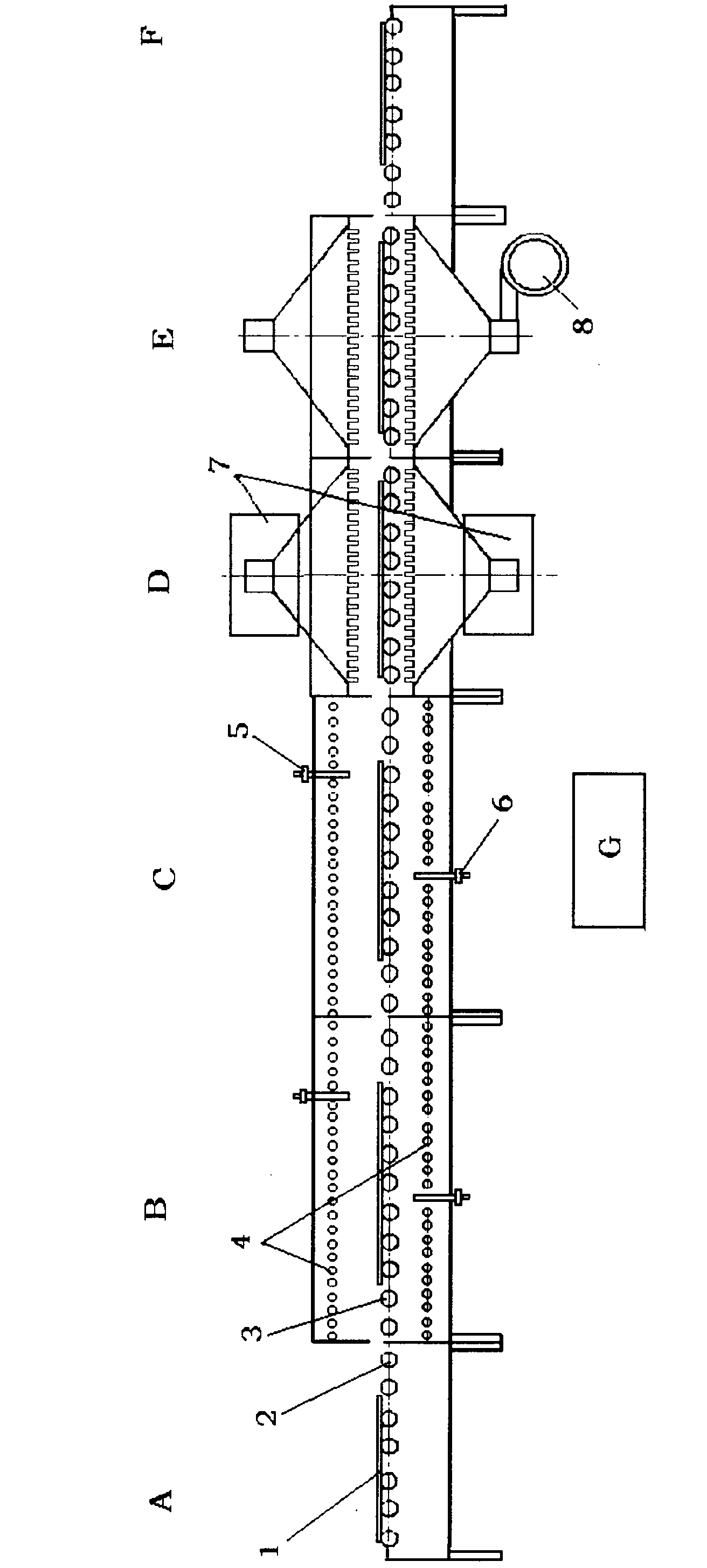

[0027] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] According to the order requirements, each batch of thin glass to be tempered is sampled. In the laboratory, use a special glass tempering parameter measuring device to accurately measure the viscosity-temperature curve, softening point and formulate tempering process control parameters, and input them into the computer center control system (G ).

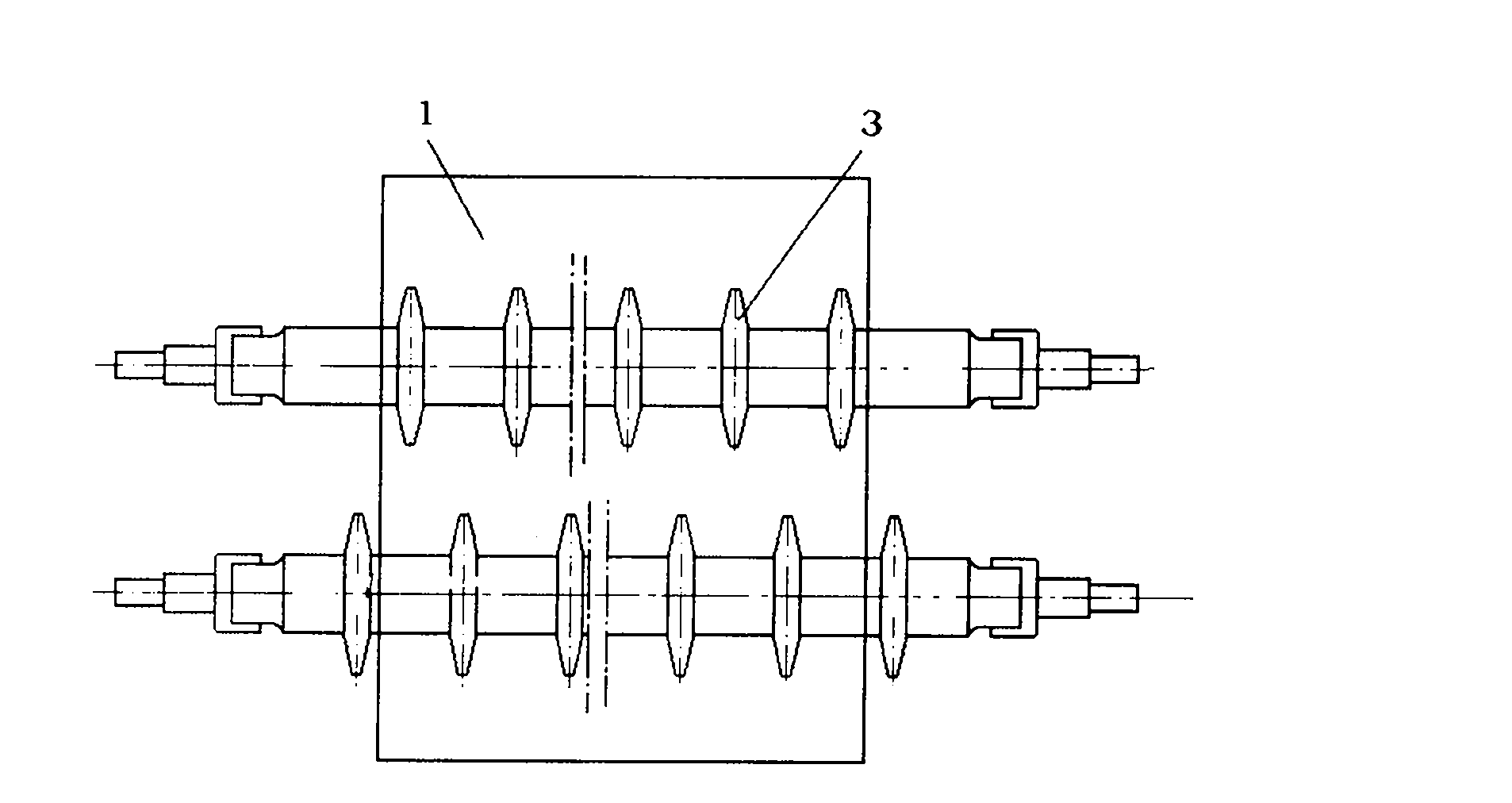

[0029] Put the thin glass original sheet (1) that has been cold-processed (edge grinding, punching, etc.) on the sheet table (A) of the ultra-flat tempered glass production equipment. The computer center control system (G) starts the conveying system (2) according to the predetermined program to send the glass into the main heating chamber (B) and swing it. The quartz glass tube infrared heater (4) heats the glass (1) from room temperature to a temperature 20°C-40°C (ie 565°C-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com