Industrialized production method of transference-resistant blue light red pigment for PU (Poly Urethane)

A production method and migration-resistant technology, applied in the direction of organic dyes, etc., can solve problems such as troubles and migration of downstream enterprises, and achieve the effect of less application difficulty, low equipment requirements, and improved color light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

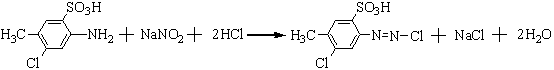

[0029] 1) Put 200Kg of 2-chloro-4-aminotoluene-5-sulfonic acid into a common reaction kettle, add 2000Kg of water, 180Kg of liquid caustic soda with a content of 30%, and heat up to 90°C to dissolve into salt for 1 hour; then quickly add 320Kg of 30% % hydrochloric acid, then slowly add 240Kg of 30% sodium nitrite solution at 0°C to carry out diazotization and stirring reaction for 1 hour, and remove excess sodium nitrite with sulfamic acid to obtain diazonium solution;

[0030] 2) Inject 200Kg of 3-hydroxy-2-naphthoic acid into the coupling reaction kettle, add 420Kg of liquid caustic soda with a content of 30%, and stir until the 3-hydroxy-2-naphthoic acid is dissolved;

[0031] 3) At 15°C, add the diazo solution to the coupling reaction kettle in step 2) within 30 minutes for coupling reaction, and stir for 2 hours after adding the diazo solution;

[0032] 4) Inject 200Kg of calcium chloride into the coupling reaction kettle, stir for 1 hour, inject 100Kg of strontium nitra...

Embodiment 2

[0035] 1) Put 200Kg of 2-chloro-4-aminotoluene-5-sulfonic acid into a common reaction kettle, add 2000Kg of water, 180Kg of liquid caustic soda with a content of 30%, and heat up to 95°C to dissolve into salt for 0.8 hours; then quickly add 320Kg of 30% % hydrochloric acid, then at -10°C, add 600Kg of 30% sodium nitrite solution for 15 minutes to carry out diazotization and stirring reaction for 1 hour, and remove excess sodium nitrite with sulfamic acid to obtain diazonium solution;

[0036] 2) Inject 300Kg of 3-hydroxy-2-naphthoic acid into the coupling reaction kettle, add 510Kg of liquid caustic soda with a content of 30%, and stir until the 3-hydroxy-2-naphthoic acid is dissolved;

[0037] 3) At 30°C, add the diazo solution into the coupling reaction kettle for coupling reaction within 50 minutes, and stir at this temperature for 4 hours after the diazo solution is added;

[0038] 4) Inject 350Kg of calcium chloride into the coupling reaction kettle, stir for 1 hour, inje...

Embodiment 3

[0040] 1) Put 200Kg of 2-chloro-4-aminotoluene-5-sulfonic acid into a common reaction kettle, add 2000Kg of water, 180Kg of liquid caustic soda with a content of 30%, and heat up to 85°C to dissolve into salt for 1.2 hours; quickly add 320Kg with a content of 30% hydrochloric acid, then at a temperature of 30°C, add 280Kg of 30% sodium nitrite solution within 10 minutes to carry out diazotization and stirring reaction for 1 hour, and remove excess sodium nitrite with sulfamic acid to obtain diazonium solution;

[0041] 2) Inject 300Kg of 3-hydroxy-2-naphthoic acid into the coupling reaction kettle, add 420Kg of liquid caustic soda with a content of 30%, and stir until the 3-hydroxy-2-naphthoic acid is dissolved;

[0042] 3) At 15°C, add the diazo solution into the coupling reaction kettle within 40 minutes for coupling reaction, and stir for 2 hours after adding the diazo solution;

[0043] 4) Inject 400Kg of calcium chloride into the coupling reaction kettle, stir for 1 hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com