Prestretching-pretwisting type full-bridge 2D electro-hydraulic proportional directional valve

An electro-hydraulic proportional and full-bridge technology, which is applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problem of leakage flow of the pilot control stage that cannot work normally, large flow rate of the pilot-control electro-hydraulic proportional valve, stuck pilot Problems such as the level control oil circuit can be overcome to overcome adverse effects, the structure is simple, and the effect of proportional control function is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

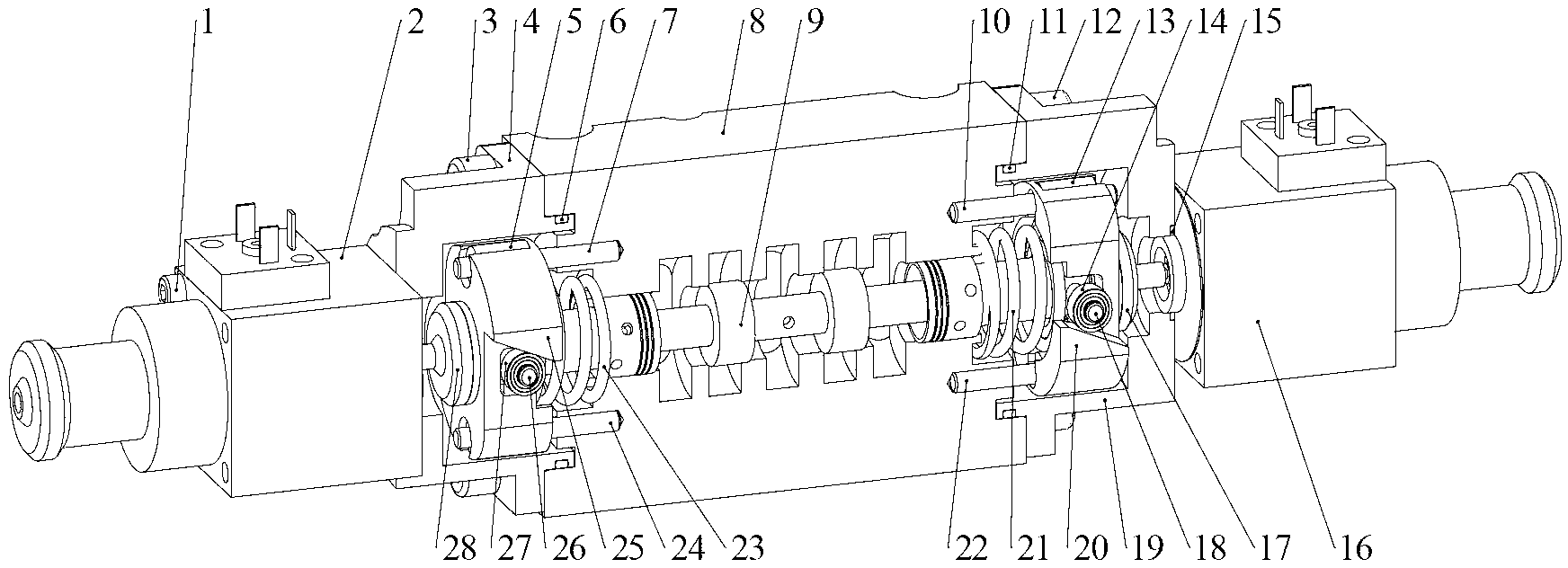

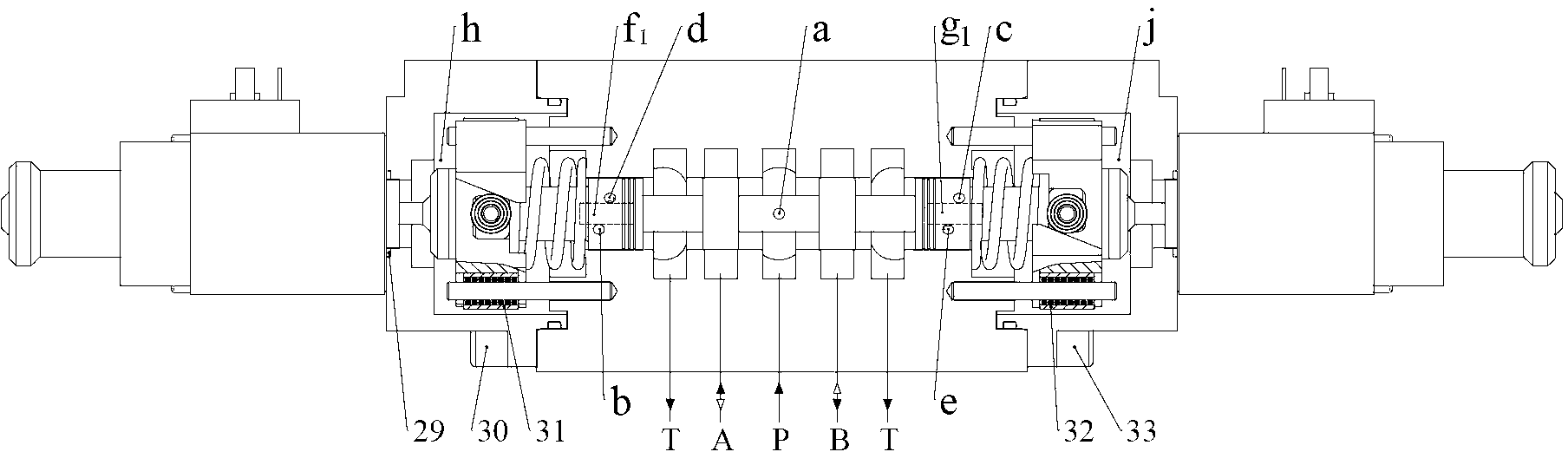

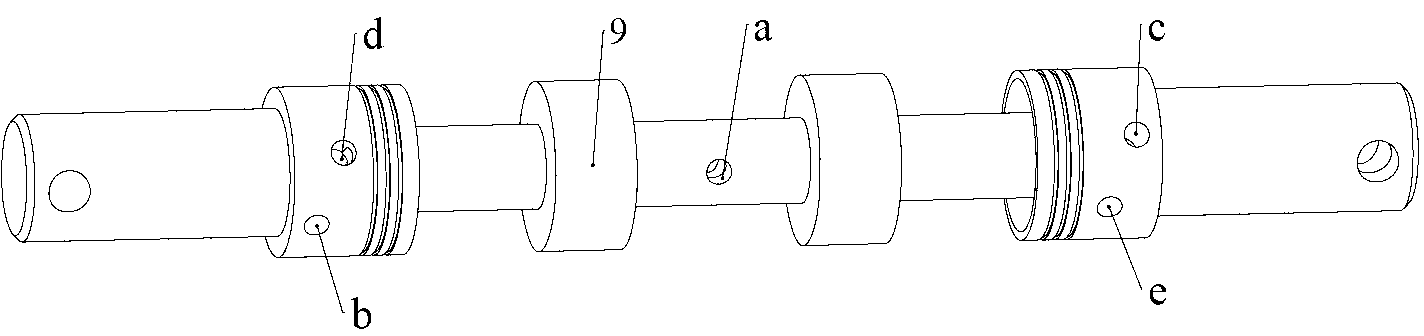

[0027] refer to Figure 1 to Figure 10 , a pre-tensioned-pre-twisted full bridge 2D electro-hydraulic proportional reversing valve includes screws 1, 3, 12, 30, 33, linear electro-mechanical converters 2, 16, end covers 4, 19, linear bearings 5 , 13, 31, 32, cylindrical compression spring 21, 23, O-ring 6, 11, 15, 29, pin 7, 10, 22, 24, valve body 8, valve core 9, rolling bearing 14, 27, 36, 38, top cover 17,28, bearing pin 18,26, sliding wedge 20,25, tightening screw 34, steel ball 35, sleeve 37,39.

[0028] The pre-tension-pre-twist type full-bridge 2D electro-hydraulic proportional reversing valve consists of three parts: 2D valve, linear electro-mechanical converter and compression-torsion coupling.

[0029] The 2D valve part includes a spool 9 and a valve body 8, the spool 9 is rotatably and axially slidably arranged in the inner hole of the valve body 8, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com