Artificial hip joint dynamic fatigue wear sample clamp and tester

A sample fixture and wear test technology, which is applied in the field of medical equipment, can solve the problems of inability to provide continuous force, and achieve the effect of simple structure, convenient installation and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

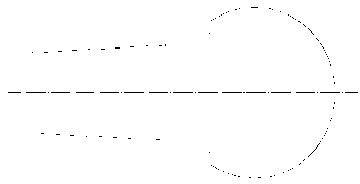

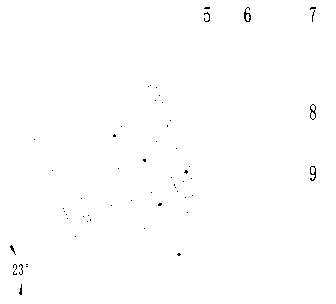

[0016] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. An artificial hip joint dynamic fatigue wear sample fixture, including a femoral head sample fixing part and an acetabular sample fixing part that drives the femoral head to rotate, wherein the acetabular sample fixing part includes a base 7 and an inclined tray 9, and the acetabular test piece The sample 6 is directly placed in the base 7, and the base 7 is placed in the inclined tray 9, and there is an included angle between the inclined tray 9 and the horizontal direction, and the included angle is determined according to the actual structure of the human body, generally 23?? During use, the femoral head sample 5 is quickly installed in the femoral head sample fixing part, the acetabular sample 6 is placed in the base 7 through the circular groove at the bottom of the acetabular sample 6, and then the base 7 is placed Slant tray 9. If a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com