MEMS Fabry-Perot cavity tunable filter

A tunable filter and Perot cavity technology, which is applied in the field of MEMS Fabry-Perot cavity tunable filter, can solve the problems that cannot meet the requirements of optical communication, narrow tuning range, slow switching speed, etc., and achieve narrow bandwidth, Low cost and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

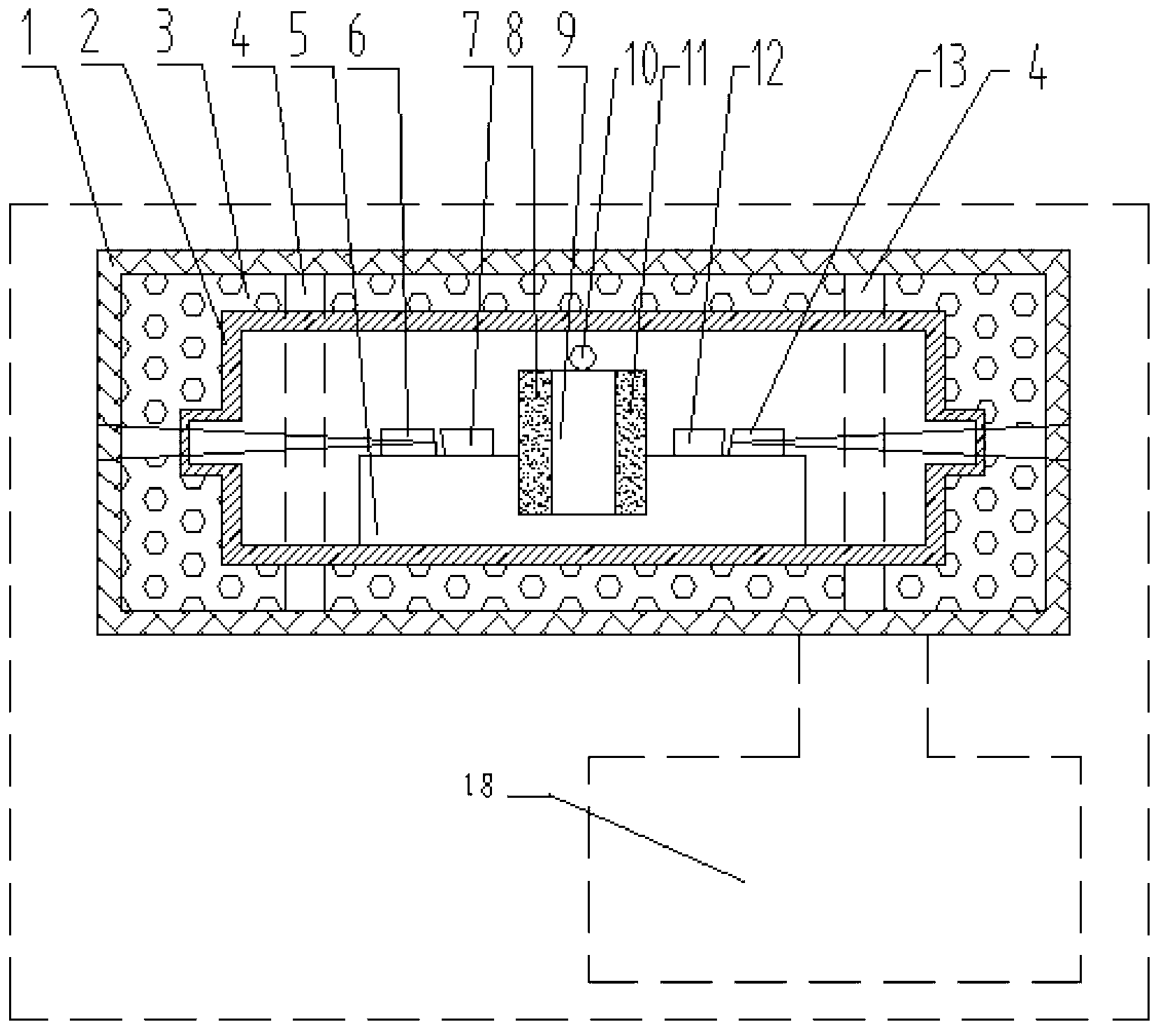

[0053] Embodiments of the invention. MEMS Fabry-Perot cavity tunable filters, such as figure 1 As shown, the structure includes:

[0054] The thermal insulation outer box 1 can be made of polytetrafluoroethylene;

[0055] The sealed inner box 2 can be made of Kovar metal material;

[0056] The thermal insulation material 3 filled between the thermal insulation outer box 1 and the sealed inner box 2 can be thermal insulation quartz wool;

[0057] The damping material 4 surrounding the sealed inner box 2 can be a silicone rubber hose;

[0058] fixed on the metal fixed base 5 on the bottom surface of the sealed inner box 2;

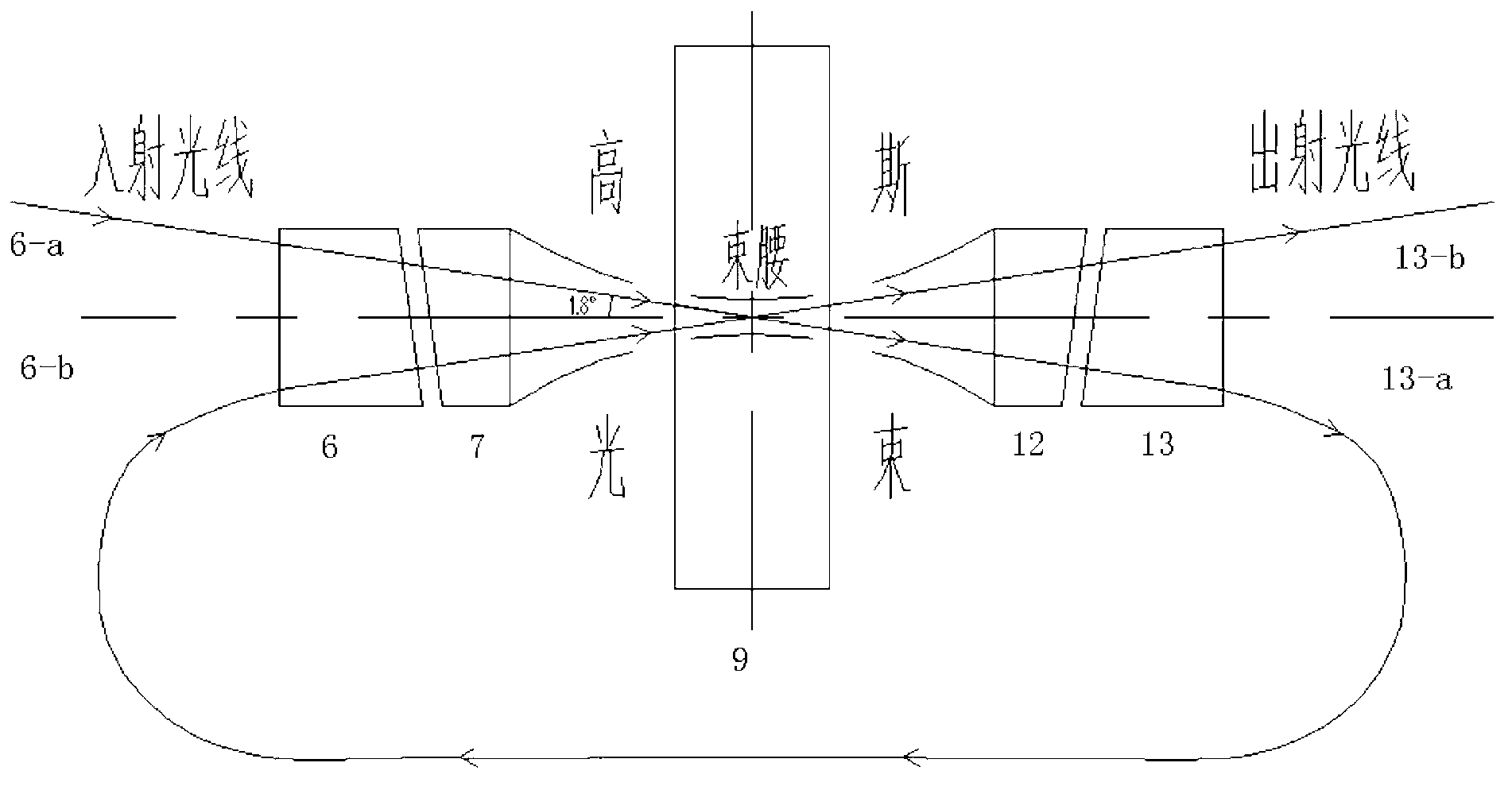

[0059] The incident end double fiber optic ferrule 6 fixed on the metal fixed base 5, the incident end collimator lens 7, the first heating power resistor 8, the MEMS Fabry-Perot cavity chip 9, the second heating power resistor 11, the output end Collimating lens 12, double fiber optic ferrule 13 at the exit end;

[0060] A thermistor 10 fixed on the M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com