Method for manufacturing high-energy-density and high-power-density asymmetric supercapacitor based on eggshell inner membranes

A technology with high power density and high energy density, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of unfavorable safe use of supercapacitors, increased specific capacity of activated carbon materials, and inconvenient assembly, so as to achieve environmental friendliness and reduce costs. Pollution, the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

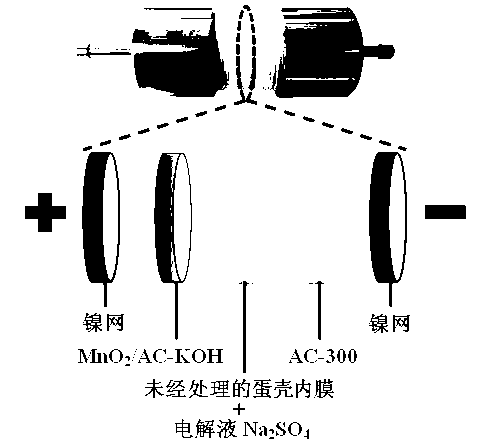

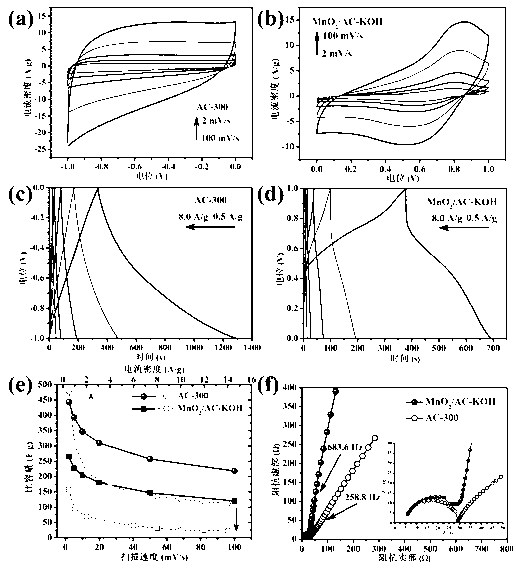

[0031] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0032] The method for making an asymmetric supercapacitor with high energy density and high power density based on the eggshell inner membrane of this embodiment comprises the following steps:

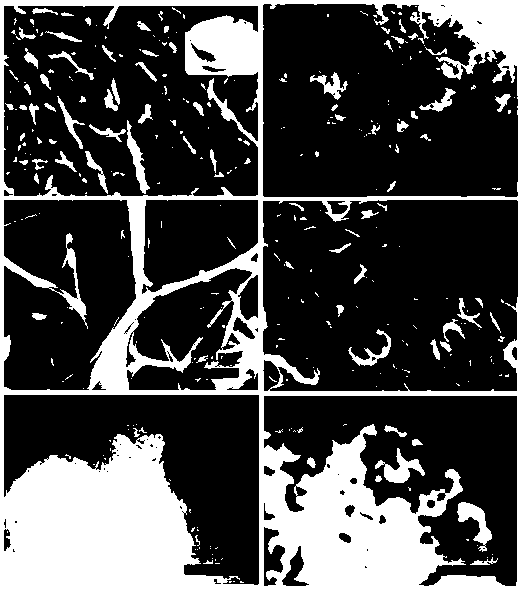

[0033] 1) Peel and clean the eggshell inner membrane from the eggshell: use 1mol / L HCl to remove the calcium carbonate outside the eggshell, and then clean the peeled eggshell inner membrane with deionized water;

[0034] 2) The eggshell inner membrane obtained in step 1) was heated to 800°C for 2 hours in an argon atmosphere at a heating rate of 1°C / min for carbonization treatment; the carbonized eggshell inner membrane was respectively treated with 2mol / L KOH and 2mol / L of HCl for cleaning to remove impurities contained in it;

[0035] 3) Heat the carbonized eggshell inner membrane obtained in step 2) to 300°C in the air at a heating rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com