Radio frequency modulation tunable all-fiber laser based on fiber loop mirror

A radio frequency modulation and ring mirror technology, applied in the laser field, can solve the problems of narrow adjustment range, inconvenient adjustment of the grating efficiency, low output power, etc., and achieve the effect of good beam quality, compact structure and continuous tuning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

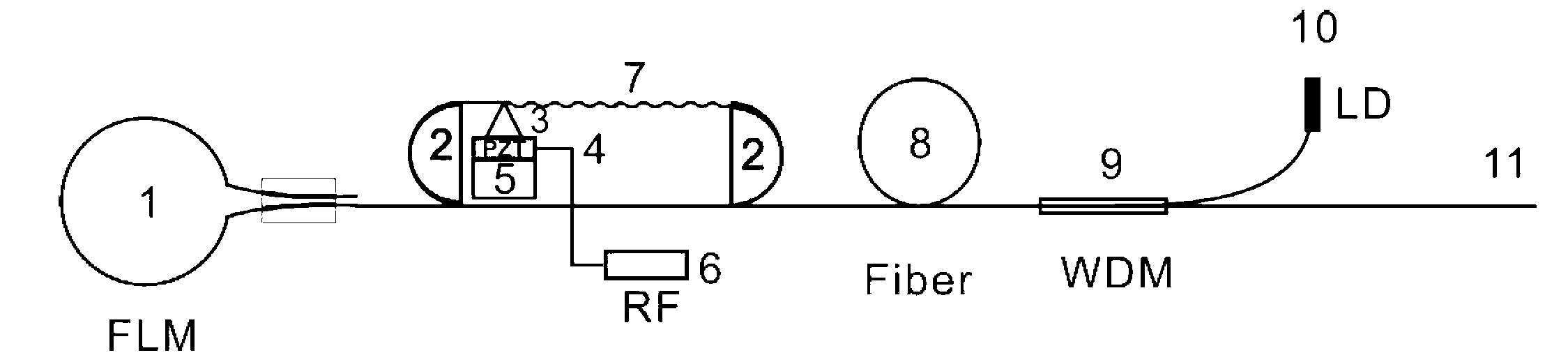

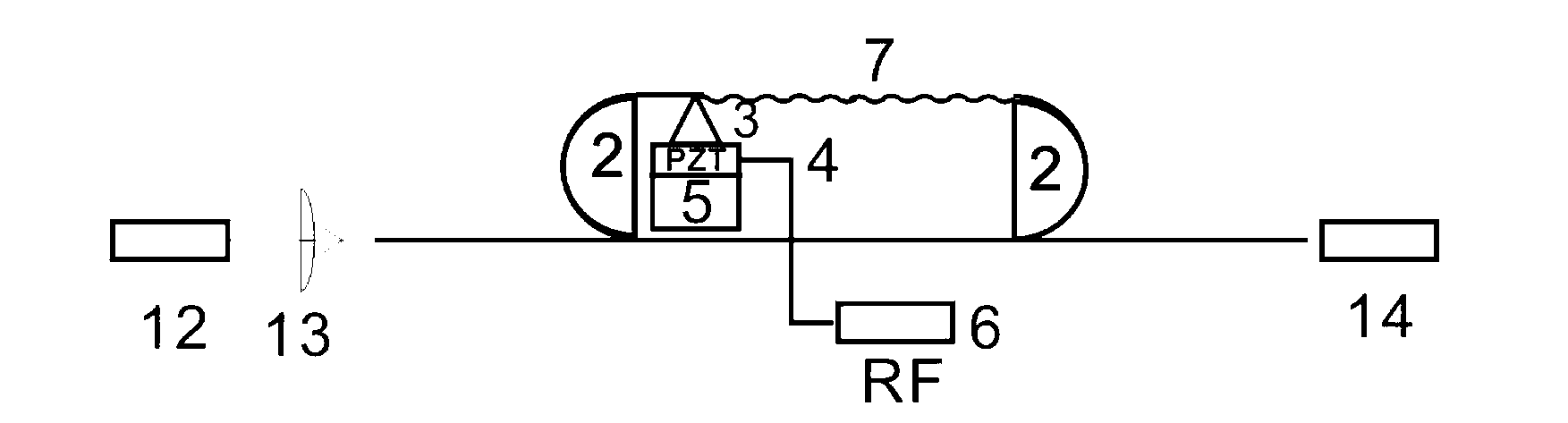

[0036] Such as figure 1 As shown, following the above-mentioned technical solution of the present invention, the RF-modulated tunable all-fiber laser based on the fiber loop mirror of this embodiment includes four parts: a resonator, a gain fiber, a pump source and a tunable filter.

[0037] Resonant cavity: the total reflection mirror is a fiber optic loop mirror with a coupling ratio of 50:50, and the output mirror is a 4% non-Nier reflection of the fiber cut end face of the output pigtail 11. Both are wide-spectrum mirrors and can be adapted to any doped Stray fiber and any wavelength.

[0038] Gain fiber: double-clad doped fiber 8 selects thulium-doped double-clad fiber of 6 / 125μm, the cladding absorption rate is 1.4dB / m790nm, that is, the cladding absorption rate at 790nm is 1.4dB / m, the core value The aperture is 0.23, and the fiber length is 10m. Since the thulium-doped fiber has a wider gain spectrum, it can achieve a larger tuning range; for other doped fiber lasers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com