Stress control body for plastic insulated high voltage DC cable terminal

A HVDC, cable termination technology, applied in cable accessories, cable installation, electrical components, etc., can solve the problems of lack of qualified plastic insulated HVDC cable termination, unreasonable electric field distribution, etc., to achieve excellent uniform electric field distribution, reduce The effect of small interfacial space charge, high DC breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

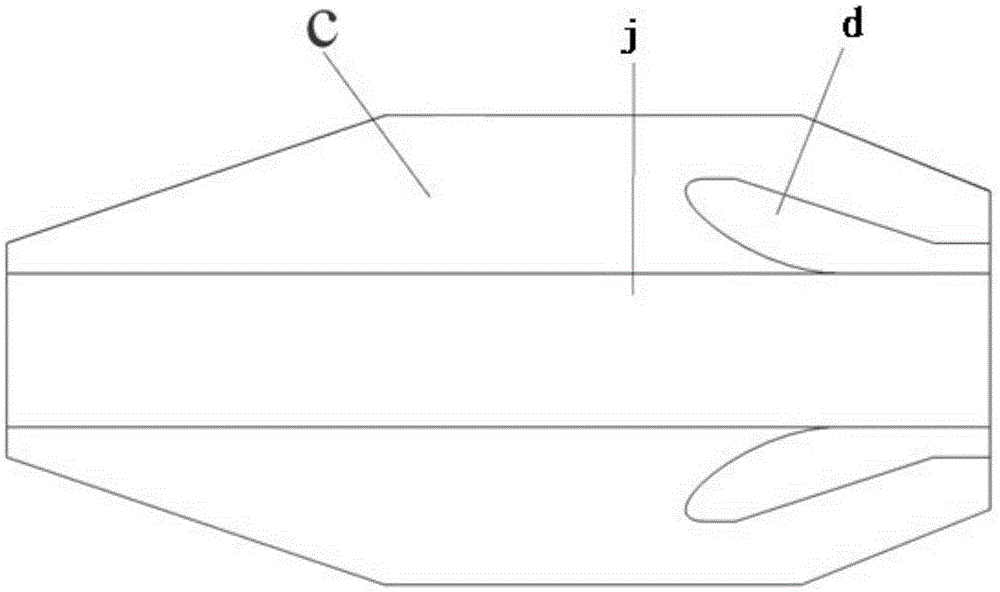

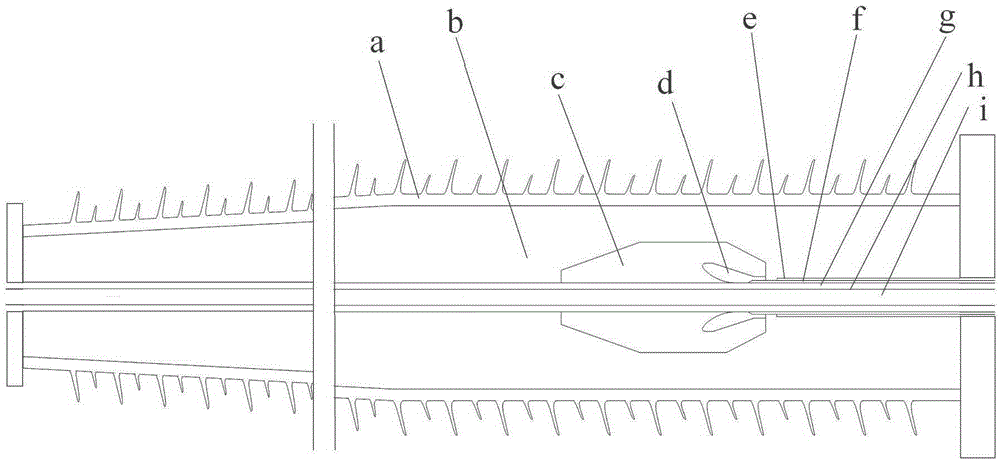

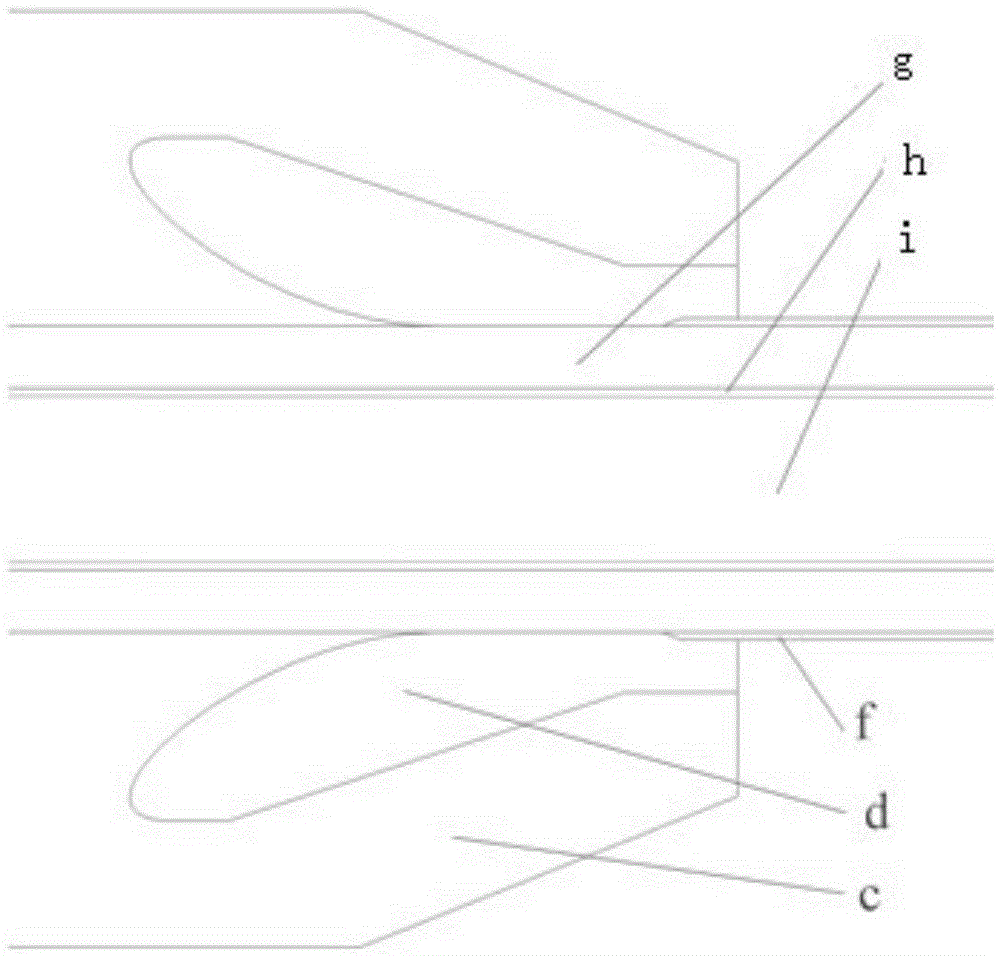

[0019] Specific embodiment 1: The stress control body for plastic insulated high-voltage DC cable terminal of this embodiment is composed of a reinforced insulator and a stress cone. The stress cone is arranged at one side port of the reinforced insulator. The stress cone is horn-shaped and the stress cone is shaped like a horn. The inner cone curve is a cubic Bezier curve, and the other side of the reinforced insulator is a trapezoid; the plastic insulated high-voltage DC cable terminal is expanded with a stress control body and installed to the cable end;

[0020] The reinforced insulator is made of high-performance silicone rubber-based conductivity nonlinear insulating material or EPDM rubber-based conductivity nonlinear insulating material; the high-performance silicone rubber-based conductivity nonlinear insulating material is a compounded silicone rubber-based conductivity Non-linear insulating material or liquid silicone rubber-based conductive non-linear insulating materi...

specific Embodiment approach 2

[0025] Specific embodiment two: this embodiment is different from specific embodiment one in that the organic peroxide is benzoyl peroxide, di-tert-butyl peroxide, dicumyl peroxide or 2,5-dimethyl- 2,5-Di-tert-butylperoxyhexane. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: This embodiment is different from specific embodiment one or two in that: mixing silicone rubber-based conductive nonlinear insulating material is mixed with 100 parts by weight of silicone rubber, 19.5 parts of non-linear functional filler, 5~ 20 parts of fumed white carbon black, 0.5-3 parts of nano-iron trioxide, 0.5-5 parts of diphenyl silicon glycol and 0.5-1.5 parts of organic peroxide. The non-linear functional filler is made of 10 parts of nano zinc oxide, It is composed of 2 parts of nano titanium dioxide, 6 parts of nano silicon carbide, 0.5 parts of carbon nanotubes, 0.5 parts of conductive carbon black and 0.5 parts of nano graphite. Other steps and parameters are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com