Polypropylene cable material under polarity inversion working condition, and preparation method and application of polypropylene cable material

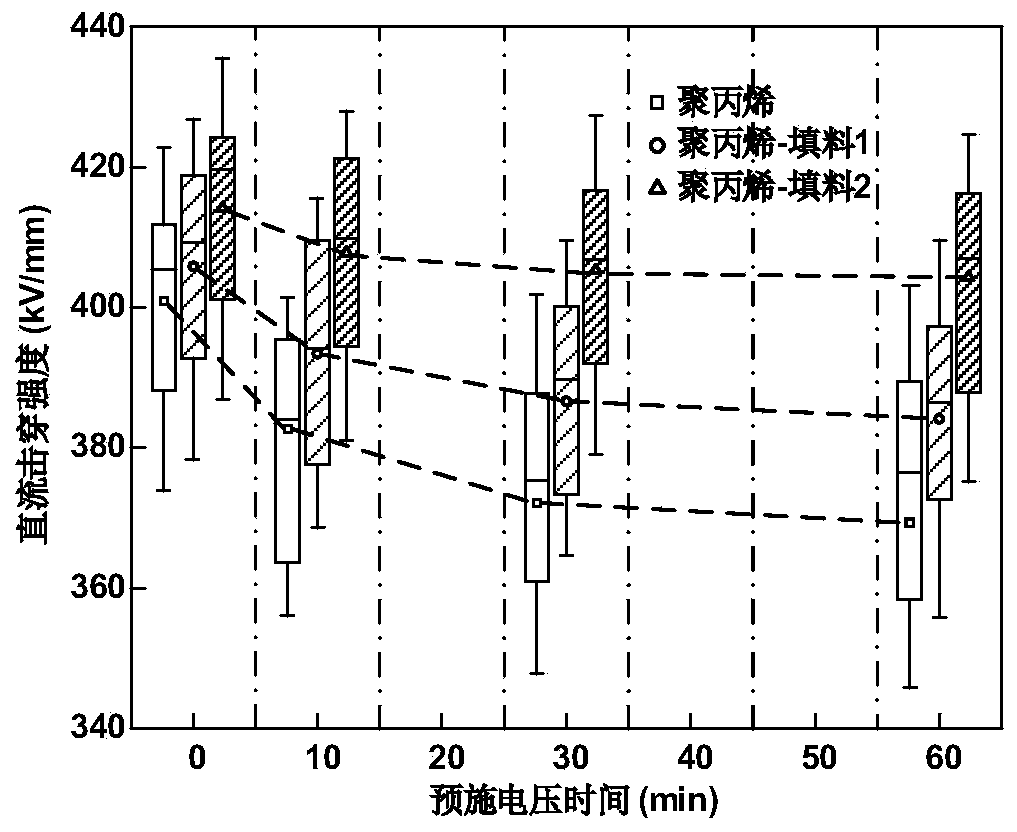

A polarity reversal, polypropylene technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of reduced breakdown strength of insulating materials, unfavorable long-term stable operation of high-voltage DC cables, etc., to reduce damage , less space charge accumulation, the effect of suppressing partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

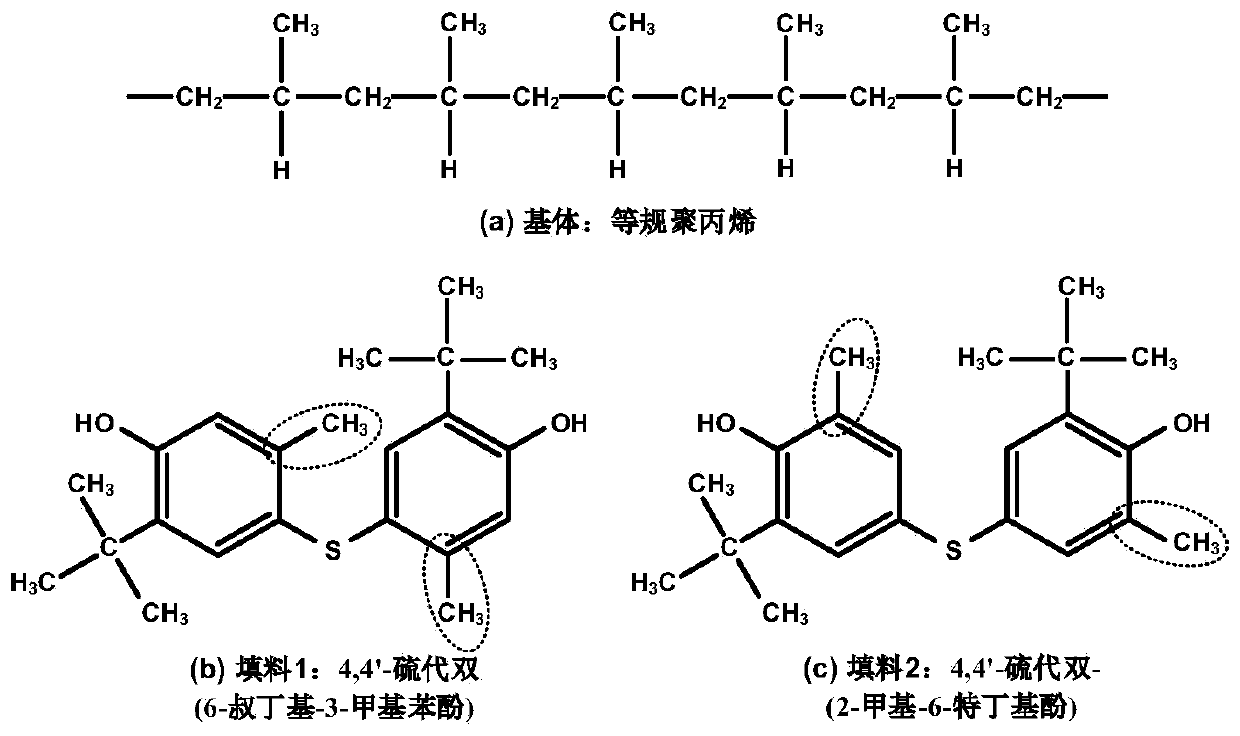

[0035] This embodiment relates to a polypropylene thermoplastic cable insulation material that improves the dielectric properties under polarity reversal conditions. The polypropylene composite insulation material includes 99.7% polypropylene matrix and 0.3% sulfur based on 100% mass fraction Substitute bisphenol compound filler. Wherein the preparation method of the polypropylene thermoplastic cable insulating material which improves the dielectric properties under the polarity reversal working condition is as follows:

[0036] A. Mix 29.91g of isotactic polypropylene particles on a two-roller machine for 10 minutes to fully melt them, and set the temperature to 200°C;

[0037] B. Suspend mixing, mix 0.09g 4,4'-thiobis(6-tert-butyl-3-methylphenol) and 4,4'-thiobis-(2-methyl-6-tertbutyl Base phenol) is mixed with isotactic polypropylene respectively, so that the additive is fully melted in the isotactic polypropylene;

[0038] C. Continue to fully knead the mixture on a two-...

Embodiment 2

[0041] This embodiment relates to a polypropylene thermoplastic cable insulation material that improves the dielectric properties under polarity reversal conditions. The polypropylene composite insulation material includes 99.5% polypropylene matrix and 0.5% sulfur based on 100% mass fraction Substitute bisphenol compound filler. Other steps are with embodiment 1.

Embodiment 3

[0043] This embodiment relates to a polypropylene thermoplastic cable insulation material that improves the dielectric properties under polarity reversal conditions. The polypropylene composite insulation material includes 99.6% polypropylene matrix and 0.4% sulfur based on 100% mass fraction Substitute bisphenol compound filler. Other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com