Apparatus and process for production of catalyst, and process for production of unsaturated acid or unsaturated nitrile

A technology for a manufacturing device and a manufacturing method, applied in the field of manufacturing unsaturated acid or unsaturated nitrile, can solve the problems of low solution stability, precipitation, inability to send aqueous mixed solution, and catalyst performance reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0230] (manufacture of niobium raw material solution)

[0231] A niobium raw material solution was produced by the following method. First, mix 80.2% by mass Nb in 500kg of water 2 o 5 76.33kg of niobic acid and oxalic acid dihydrate [H 2 C 2 o 4 2H 2 O] 290.2 kg. The added oxalic acid / niobium molar ratio was 5.0, and the added niobium concentration was 0.532 (mol-Nb / kg-liquid). By heating and stirring this liquid at 95°C for 1 hour, an aqueous solution in which the Nb compound was dissolved was obtained. After the aqueous solution was left to stand and ice-cooled, the solid was filtered by suction filtration to obtain a uniform aqueous solution of the Nb compound. The same operation was repeated several times, and the obtained aqueous solutions of Nb compounds were combined to obtain a niobium raw material solution. According to the following analysis, the molar ratio of oxalic acid / niobium in this niobium raw material solution was 2.4.

[0232] Accurately weigh 10 ...

Embodiment 2

[0256] (manufacture of niobium raw material solution)

[0257] It carried out similarly to Example 1.

[0258] (Preparation of aqueous mixture)

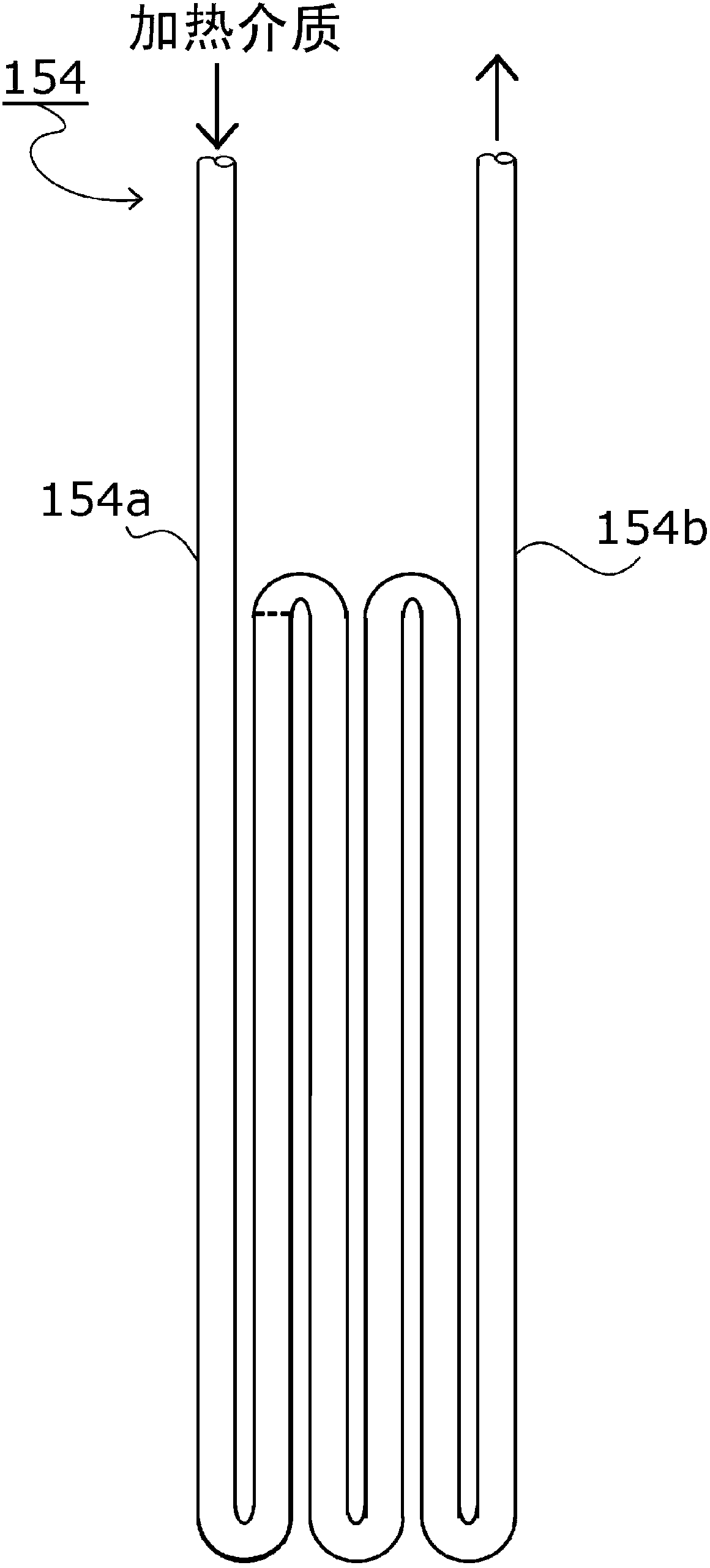

[0259] As a temperature adjustment device 150 (pipe type heating / cooling equipment) having both functions of heating and cooling, a figure 2 The heat exchanger of the same heat transfer tube 154 shown in the heat transfer tube, the material of the heat transfer tube 154 is stainless steel, and the surface of the outer side of the region 154a where the heating medium is high temperature is coated with fluorocarbon resin (trade name "Teflon PTFE ", manufactured by Du Pont-Mitsui Fluorochemicals Co., Ltd.). As a material for the inner surface of the mixed liquid tank 110, a fluorocarbon resin (trade name "Teflon PTFE", manufactured by Du Pont-Mitsui Fluorochemicals Co., Ltd.) was used. A fluorocarbon resin (trade name "Teflon PTFE", manufactured by Du Pont-Mitsui Fluorochemicals Co., Ltd.) was used as the material of the portion of ...

Embodiment 3

[0279] (manufacture of niobium raw material solution)

[0280] It carried out similarly to Example 1.

[0281] (Preparation of aqueous mixture)

[0282] As a temperature adjustment device 150 (pipe type heating / cooling equipment) having both functions of heating and cooling, a figure 2 The shown heat transfer tube is the same as the heat transfer tube 154 of the heat exchanger, and the material of the heat transfer tube 154 uses a fluorocarbon resin (trade name "Teflon PFA", manufactured by Du Pont-Mitsui Fluorochemicals Co., Ltd.), as a mixed As a material for the inner surface of the liquid tank 110, fluorocarbon resin (trade name "Teflon PTFE", manufactured by Du Pont-Mitsui Fluorochemicals Co., Ltd.) was used. Other than that, the production apparatus equipped with the catalyst of the same structure as Example 1 was used.

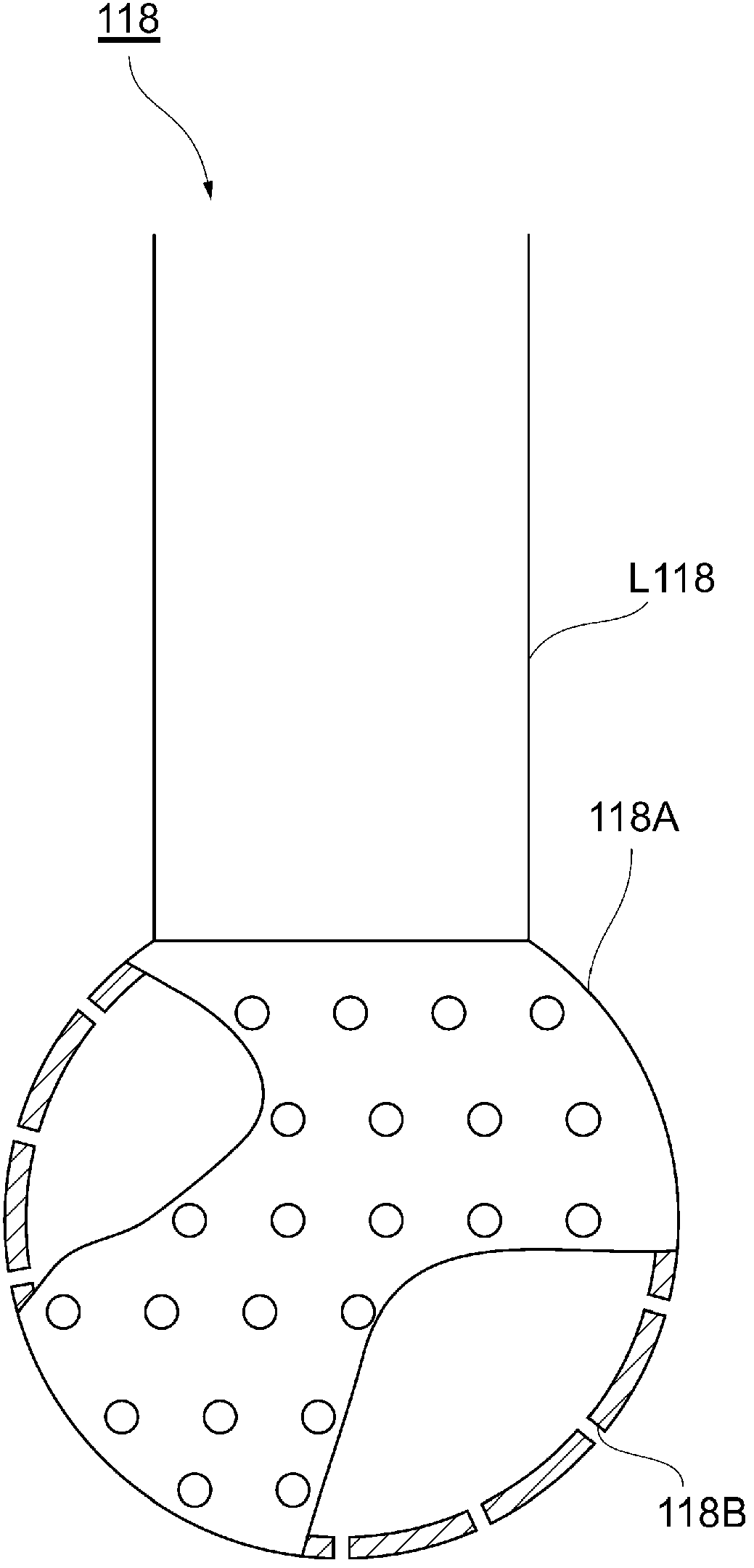

[0283] First, the dirt adhering to the mixed solution tank 110 is washed for 1 hour by the washing device 118 located in the upper part of the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com