Arc protection work clothing containing acrylic fibers

An acrylic and fiber technology, which can be used in protective devices against harmful chemicals, protective clothing, chemical characteristics of fibers, etc., and can solve problems such as increasing the weight per unit area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1-11)

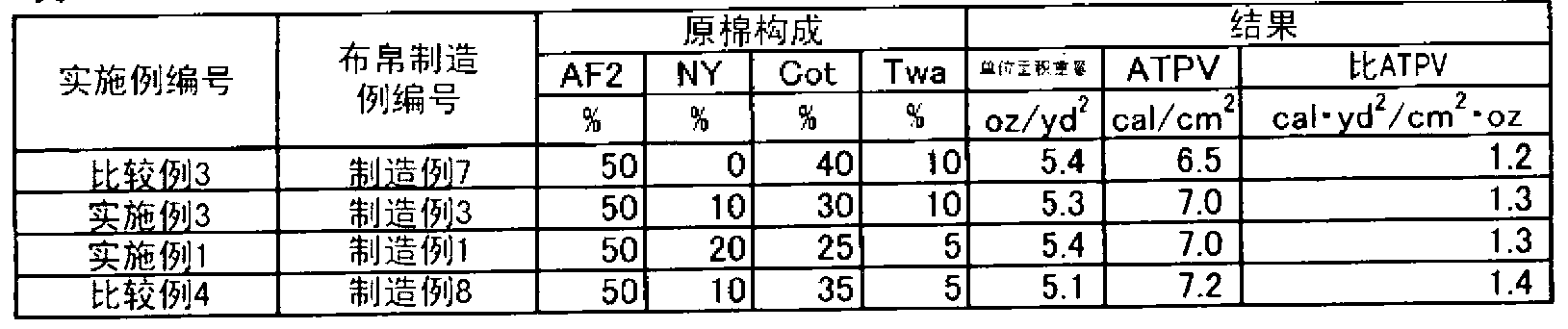

[0046] To a copolymer composed of 50% by weight of acrylonitrile, 49% by weight of vinylidene chloride, and sodium styrene sulfonate, an acrylic fiber in which 10% by weight of antimony trioxide was added to the resin weight of the copolymer (in the table, " AF1 "indicated), the acrylic fiber ( Indicated by "AF2" in the table), nylon 66 (indicated by "NY" in the table), cotton (indicated by "Cot" in the table), flame-retardant rayon (manufactured by Setrio サケュステイオ (Sateri Oy, Finland) company Visil (registered trademark), indicated by "Vis" in the table. Lenzing FR (registered trademark) manufactured by Lenzing Co., Ltd., indicated by "LFR" in the table), para-aramid fiber (Twaron (registered trademark) manufactured by Teijin Co., Ltd. ), represented by "Twa" in the table), polyethylene terephthalate (represented by "PET" in the table) is mixed with the raw cotton composition shown in Tables 1 to 5, and spun by the usual spinning method. yarn and twisted yarn to obtain spun y...

experiment example 1)

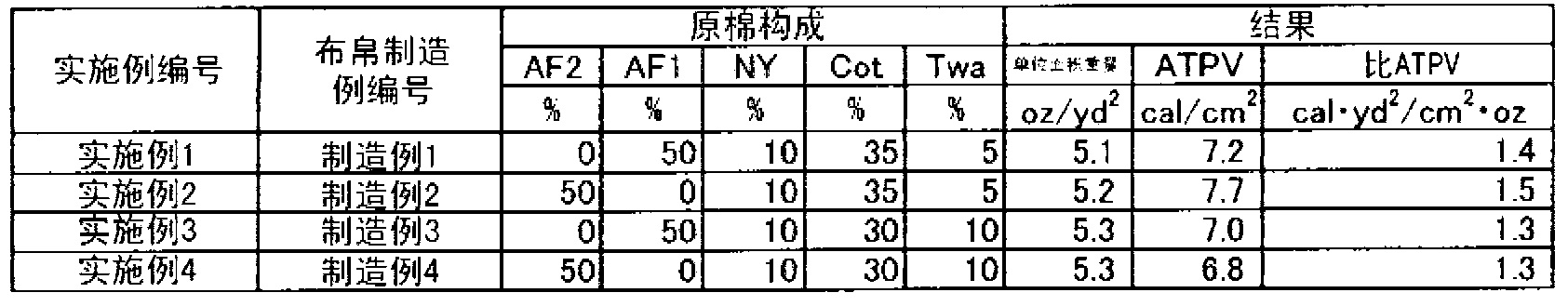

[0048] An arc test was performed on the fabrics produced in Production Examples 1 to 4. The results are shown in Table 1. AF1 (with an average content of antimony trioxide of 10% by weight) and AF2 (with an average content of antimony trioxide of 25 wt. % by weight) in Examples 1 to 4 (Manufacturing Examples 1 to 4), the ratio ATPV was 1.3 or more. It has not been sufficiently disclosed in the prior art what kind of acrylic fiber should be used when it is desired to obtain high arc resistance with a fabric having a smaller basis weight, but this point has been clarified by the present invention.

[0049] Table 1

[0050]

experiment example 2)

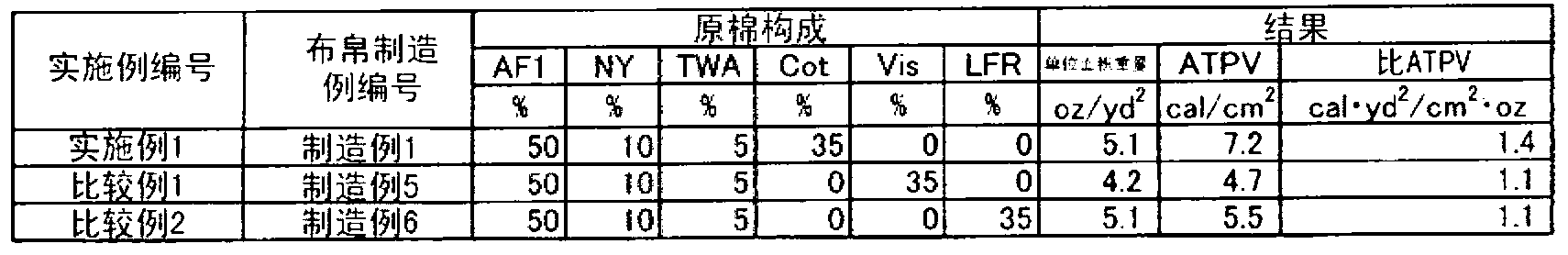

[0052] The arc test was implemented with respect to the fabric produced in manufacture example 1, 5, and 6. The results are shown in Table 2. In Example 1 (Manufacturing Example 1) in which the cellulose-based fiber used was natural cellulose-based fiber cotton, the ratio ATPV reached 1.3 or more, but in Comparative Example 1 (Manufacturing Example 1) using flame-retardant rayon 5) and Comparative Example 2 (Manufacture Example 6), the ratio ATPV was less than 1.3. U.S. Publication No. US2006 / 0292953 (Patent Document 2) describes that flame-retardant cotton can be used, but it shows that in order to obtain high arc resistance with a fabric with a lower basis weight, it is not necessary to flame-retardant cotton , Instead, it is necessary to use natural cellulose-based fibers that have not been flame-retardant.

[0053] Table 2

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com