Method for improving protective enzyme activity of turfgrass plants by utilizing air-dried sludge

A technology for air-drying sludge and turfgrass, applied in the fields of botanical equipment and methods, applications, horticulture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

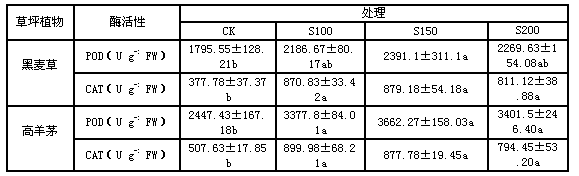

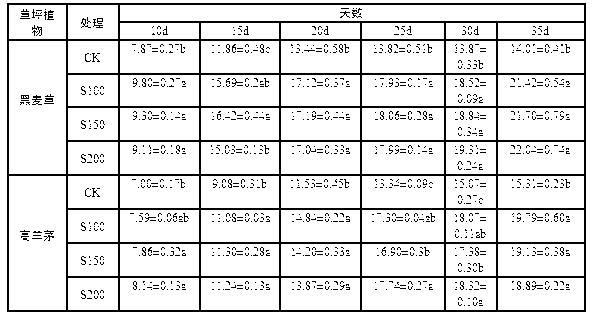

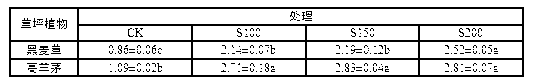

Examples

Embodiment 1

[0068] Among them, sludge: soil = 1:3; the sludge for testing is collected from Tianjin Jizhuangzi Sewage Treatment Plant, and the collected sludge is crushed through a 2mm sieve, spread flat on a plastic cloth and placed at the vent for 2 to 3 day, air-dried under natural conditions. The organic matter content of the air-dried sludge is 18.21%, the total nitrogen content is 1.41%, the available phosphorus content is 187 mg / kg, the total potassium content is 652.9 mg / kg, and the water content is 2.13%. The test soil is passed through a 2 mm sieve and placed at the vent 2-3 days, air-dried under natural conditions, soil organic matter content is 4.68%, total nitrogen content is 0.21%, available phosphorus is 22.03 mg / kg, total potassium content is 324.3 mg / kg, pH is 7.44, and saturated moisture content is 0.58 ml / g.

Embodiment 2

[0070] Wherein sludge: soil = 1:7; the sludge for testing is collected from Tianjin Jizhuangzi Sewage Treatment Plant, and the collected sludge is crushed through a 2mm sieve, laid flat on a plastic cloth and placed at the air vent for 2 to 3 day, air-dried under natural conditions. The organic matter content of the air-dried sludge is 18.21%, the total nitrogen content is 1.41%, the available phosphorus content is 187 mg / kg, the total potassium content is 652.9 mg / kg, and the water content is 2.13%. The test soil is passed through a 2 mm sieve and placed at the vent 2-3 days, air-dried under natural conditions, soil organic matter content is 4.68%, total nitrogen content is 0.21%, available phosphorus is 22.03 mg / kg, total potassium content is 324.3 mg / kg, pH is 7.44, and saturated moisture content is 0.58 ml / g.

Embodiment 3

[0072] Wherein sludge:soil=3:13; The described sludge for testing is collected from Tianjin Jizhuangzi Sewage Treatment Plant, and the collected sludge is crushed through a 2mm sieve, laid flat on a plastic cloth and placed at the air vent for 2 to 3 day, air-dried under natural conditions. The organic matter content of the air-dried sludge is 18.21%, the total nitrogen content is 1.41%, the available phosphorus content is 187 mg / kg, the total potassium content is 652.9 mg / kg, and the water content is 2.13%. The test soil is passed through a 2 mm sieve and placed at the vent 2-3 days, air-dried under natural conditions, soil organic matter content is 4.68%, total nitrogen content is 0.21%, available phosphorus is 22.03 mg / kg, total potassium content is 324.3 mg / kg, pH is 7.44, and saturated moisture content is 0.58 ml / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com