Multilayer plastic thermal insulation greenhouse and manufacturing method thereof

A technology for insulating greenhouses and plastics, applied in the fields of botanical equipment and methods, greenhouse cultivation, horticulture, etc., can solve the problems of unsatisfactory service life, inconvenient operation and management, poor wind and snow resistance, and achieve good moisturizing effect and replacement. The effect of easy damage to plastic film and strong wind and snow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

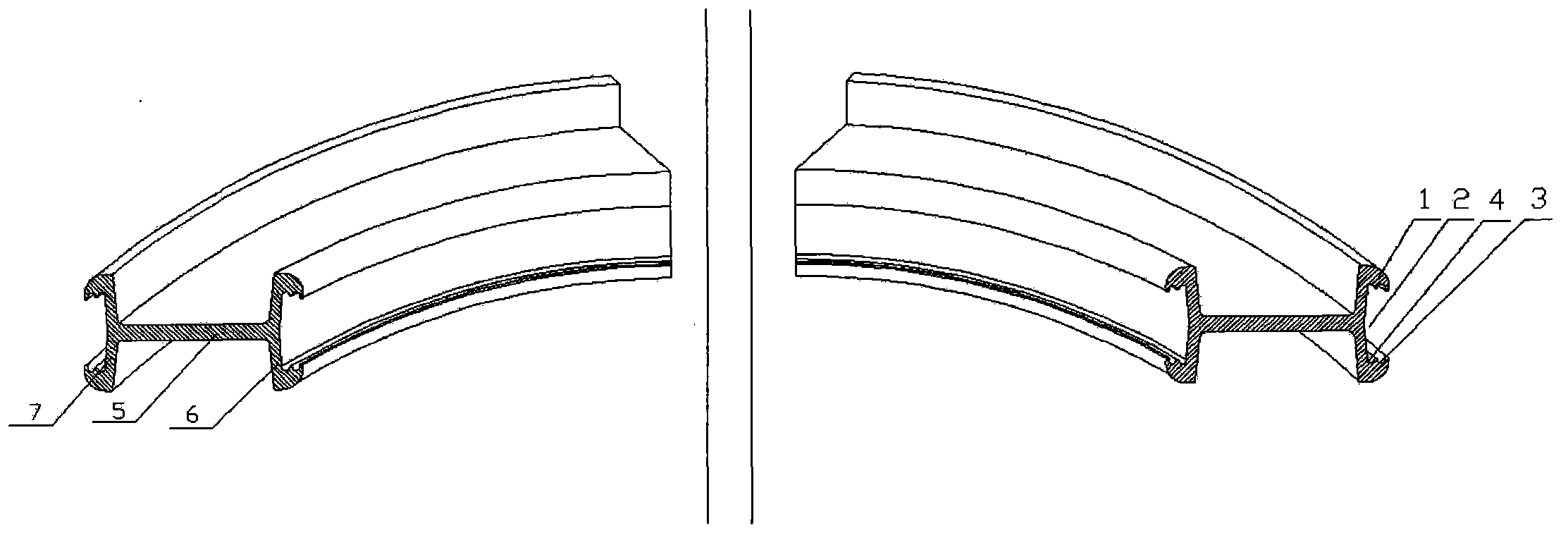

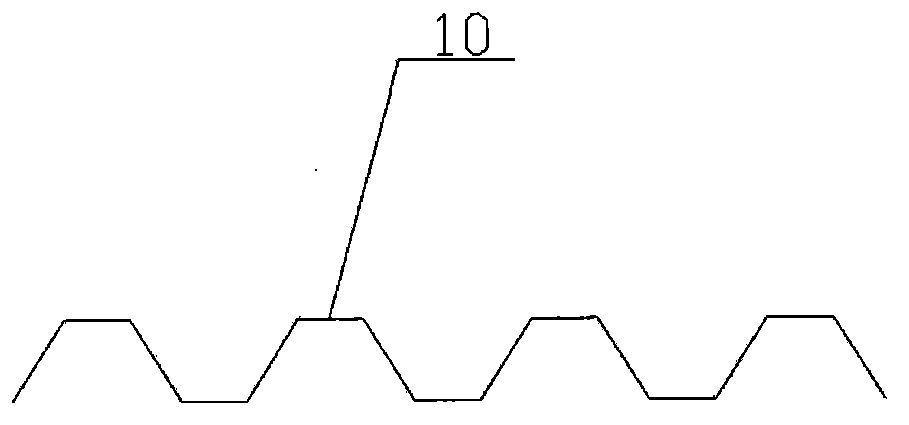

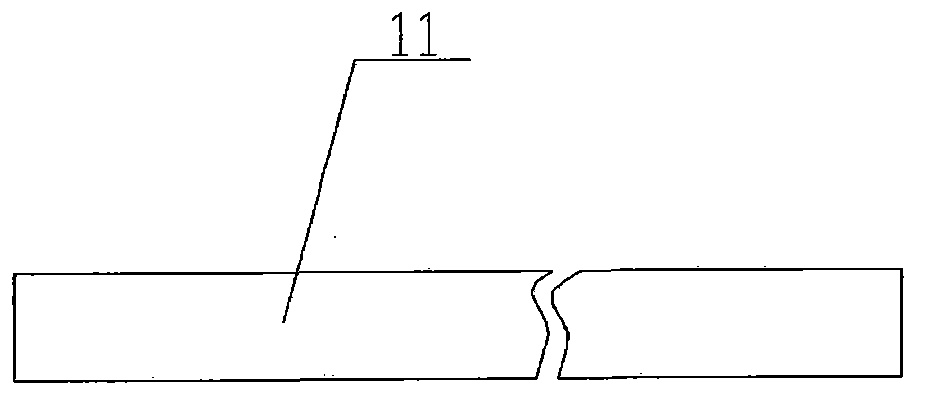

[0087] The present invention will be described below in conjunction with the accompanying drawings. like Figure 1-Figure 16 as shown, figure 1 It is a structural schematic diagram of the present invention. figure 2 It is a structural schematic diagram of the compression film spring of the present invention. image 3 It is a structural schematic diagram of the film-pressed sheet of the present invention. Figure 4 It is a structural schematic diagram of the pressure film part of the present invention. Figure 5 It is a schematic cross-sectional view of Embodiment 1 of the greenhouse beam of the present invention. Image 6 It is a schematic diagram of the first connection mode of the greenhouse beam of the present invention. Figure 7 It is a side view of the first connection mode of the greenhouse beam of the present invention. Figure 8 It is a schematic diagram of the second connection mode of the greenhouse beam of the present invention. Figure 9 It is a side view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com