Cheese-flavor toast biscuit and method for making cheese-flavor toast biscuit

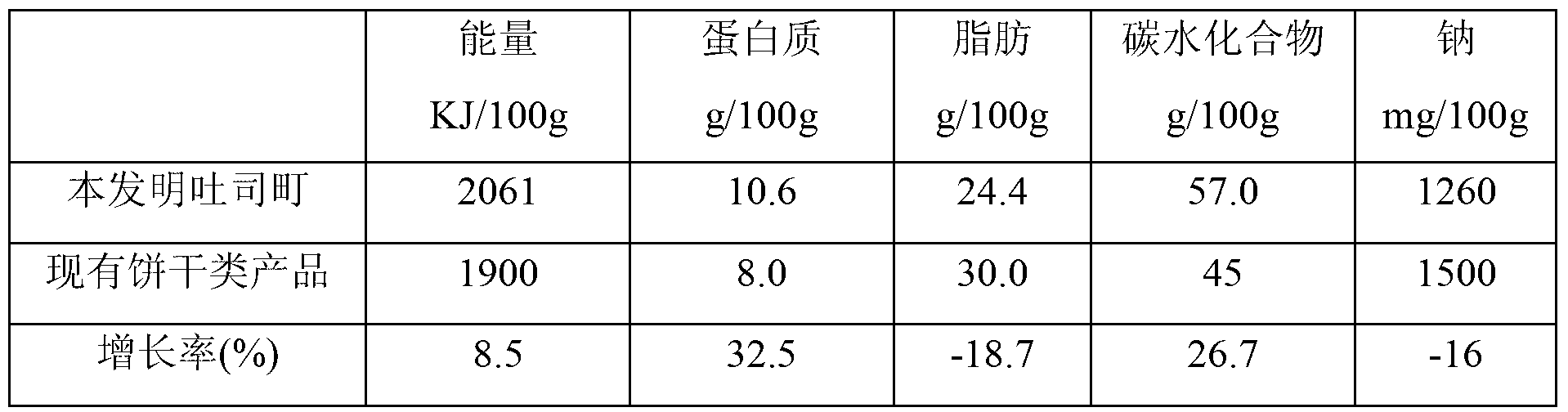

A cheese and cake embryo technology is applied to biscuit foods, the preparation of the cheese-flavored toast, and the field of cheese-flavored toast, which can solve the problems of incomplete nutritional components, high unit cost, low output rate and the like, and achieve nutritional value. The effect of richness, good quality and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Cheese-flavored toasting, including a cake base and an outer powder layer sprinkled on the outside of the cake base; the cake base is made of the following components by weight: 3 parts of water, 9.8 parts of sugar, 1.26 parts of chicken powder, carbonic acid 0.5 parts of sodium hydrogen, 1 part of salt, 4.5 parts of palm oil, 5.6 parts of eggs, 3.5 parts of milk powder, 52.5 parts of wheat flour, and 0.51 parts of dry yeast; the outer powder layer is made of the following components by weight: whole cheese powder 2 parts, 16 parts of salad oil.

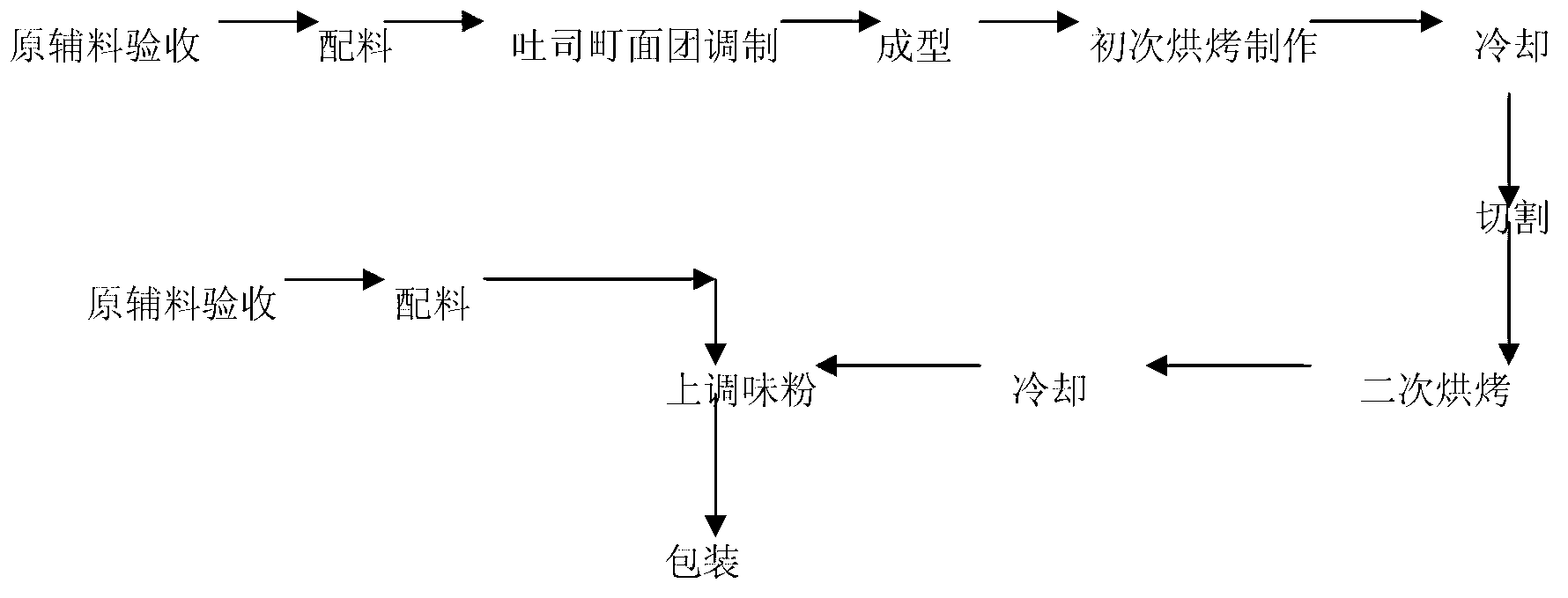

[0039] Its preparation method comprises the following steps:

[0040] 1. Dough Preparation

[0041] 1) Do a good job of preparation before seasoning, clean equipment, containers and utensils; and do a good job of disinfection.

[0042] 2) Put water, sugar, chicken powder, sodium bicarbonate, and salt into the mixing tank, stir for 4.5 minutes at 38°C to make it even, then add palm oil, eggs, milk powder, and wheat flour and ...

Embodiment 2

[0060]Cheese-flavored toasting, including a cake base and an outer powder layer sprinkled on the outside of the cake base; the cake base is made of the following components in parts by weight: 2.8 parts of water, 9.5 parts of sugar, 1.2 parts of chicken powder, carbonic acid 1.4 parts of sodium hydrogen, 0.8 parts of salt, 4.4 parts of palm oil, 5.4 parts of eggs, 3.6 parts of milk powder, 51 parts of wheat flour, and 0.45 parts of dry yeast; the outer powder layer is made of the following components by weight: whole cheese powder 1.8 parts, 15 parts of salad oil.

[0061] Its preparation method comprises the following steps:

[0062] 2. Dough Preparation

[0063] 1) Do a good job of preparation before seasoning, clean equipment, containers and utensils; and do a good job of disinfection.

[0064] 2) Put water, sugar, chicken powder, sodium bicarbonate, salt in the mixing tank, stir at 35°C for 5 minutes to make it even, then add palm oil, eggs, milk powder, wheat flour and ...

Embodiment 3

[0082] Cheese-flavored toasting, including a cake base and an outer powder layer sprinkled on the outside of the cake base; the cake base is made of the following components in parts by weight: 3.2 parts of water, 10.0 parts of sugar, 1.3 parts of chicken powder, carbonic acid 0.6 parts of sodium hydrogen, 1.2 parts of salt, 4.6 parts of palm oil, 5.6 parts of eggs, 3.4 parts of milk powder, 52 parts of wheat flour, and 0.55 parts of dry yeast; the outer powder layer is made of the following components by weight: whole cheese powder 2.2 parts, 17 parts of salad oil.

[0083] Its preparation method comprises the following steps:

[0084] 3. Dough Preparation

[0085] 1) Do a good job of preparation before seasoning, clean equipment, containers and utensils; and do a good job of disinfection.

[0086] 2) Put water, sugar, chicken powder, sodium bicarbonate, and salt into the mixing tank, stir at 40°C for 4 minutes to make it even, then add palm oil, eggs, milk powder, and whea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com