Intelligent fully-automatic steamer-filling machine and steamer-filling and feeding-supplementing method thereof

A fully automatic, retort loading technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of piercing, affecting the quality of retort, and failure of retort, so as to reduce manufacturing costs, eliminate unreliable factors and affect safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

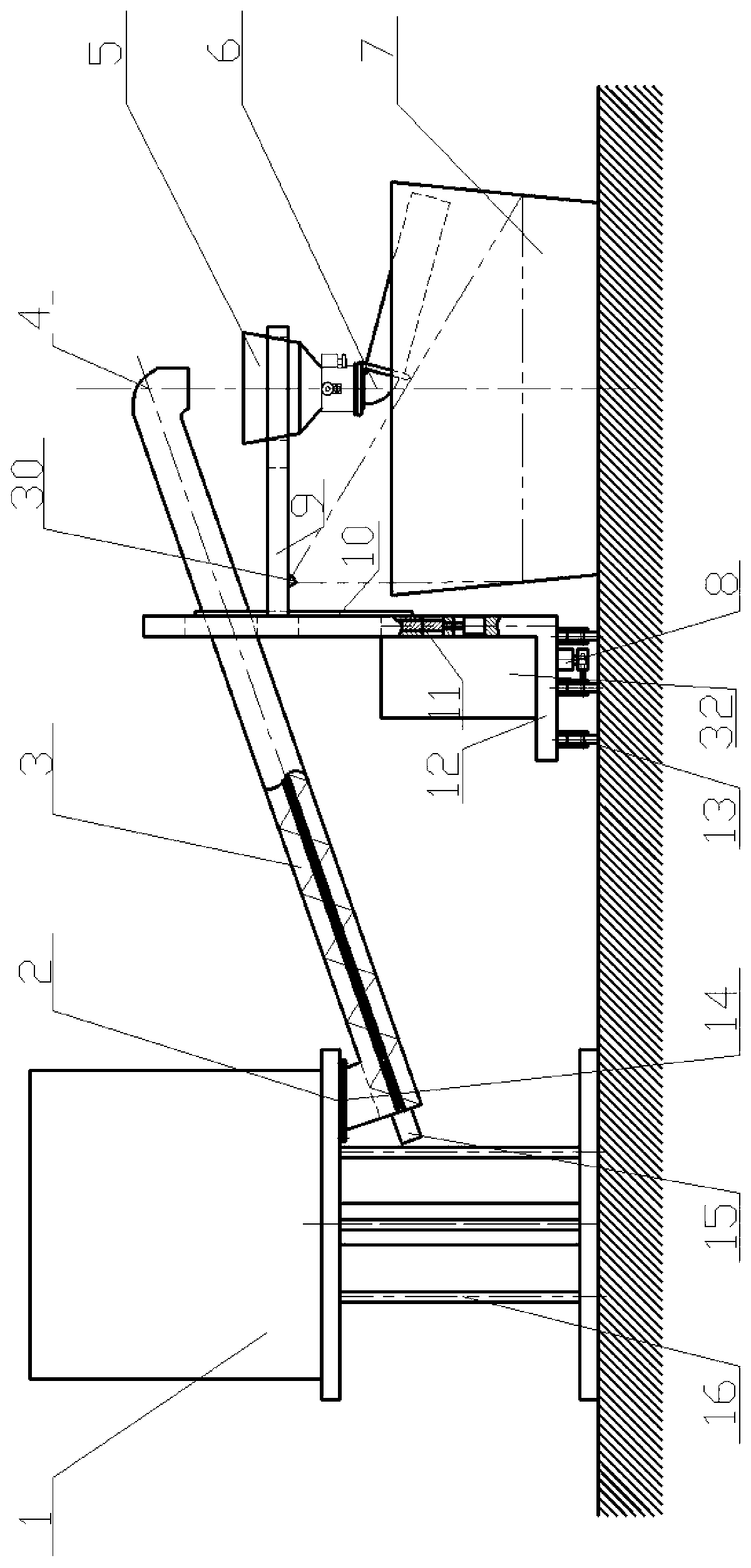

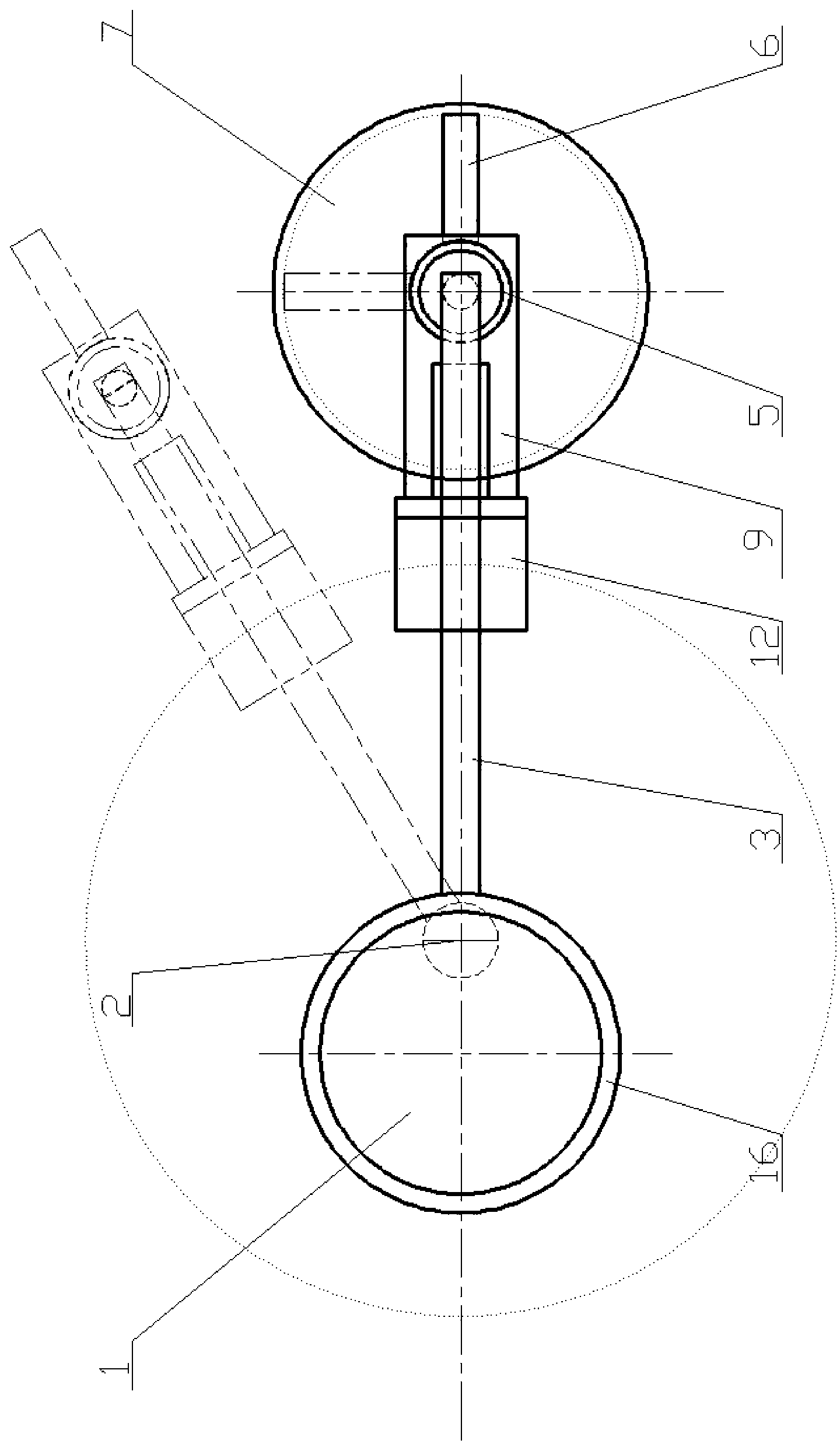

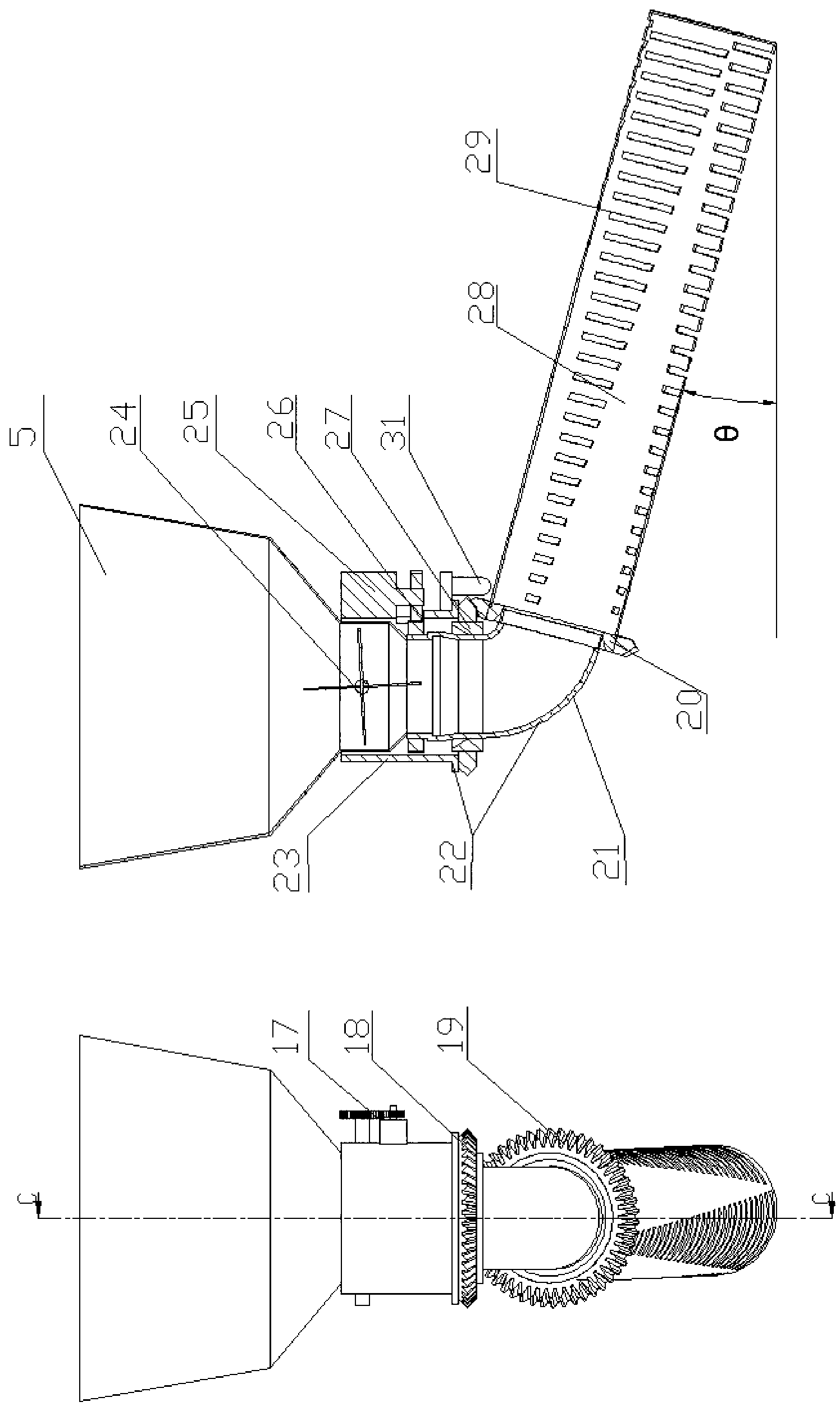

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0022] The purpose of the present invention is to provide an intelligent fully automatic retort machine, through real-time detection of surface temperature field distribution data in the material spreading area, data processing and extraction of characteristic parameters of the "running steam" area, and comparison of characteristic parameters with normal parameters to determine After feeding the area, combined with the automatic control of the amount of material spreading and the spreading device, the two operations of evenly spreading material layer by layer and feeding material in a specific area are completed alternately, so as to realize the fully automatic retort loading process. The unique spreading rotating arm of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com