High-voltage electro-static discharge (ESD) protection circuit

An ESD protection, high-voltage power supply technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as difficult to control latch-up effect, complexity, reliability problems, etc., to eliminate reliability problems, high reliability, and no reliability. Effects of Sexual Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and features of the present invention more comprehensible, the specific embodiments of the present invention will be further described below with reference to the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

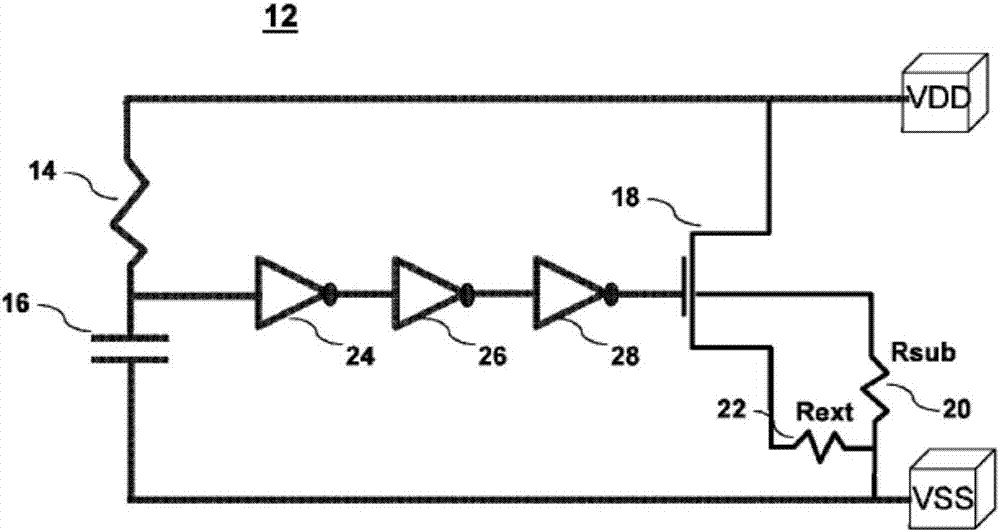

[0030] Please refer to figure 2 The present invention provides a high-voltage ESD protection circuit, which is mainly composed of three parts which are arranged between the high-voltage power line HVDD and the ground line VSS and are sequentially coupled: a bias circuit 201, an ESD trigger circuit 202, and an ESD discharge circuit 203.

[0031] In this embodiment, the bias circuit 201 is used to bias the ESD trigger circuit 202 and provide a bias voltage for it. The bias circuit 201 is mainly composed of four voltage dividing resistors R1, R2, R3, R4 connected in series between the high voltage power line HVDD and the ground line VSS, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com