Solvent type chloroprene rubber adhesive with excellent weather ability and preparation method thereof

A neoprene and solvent-based technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor heat resistance, affecting performance, poor cold resistance, etc., and achieve good cold resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

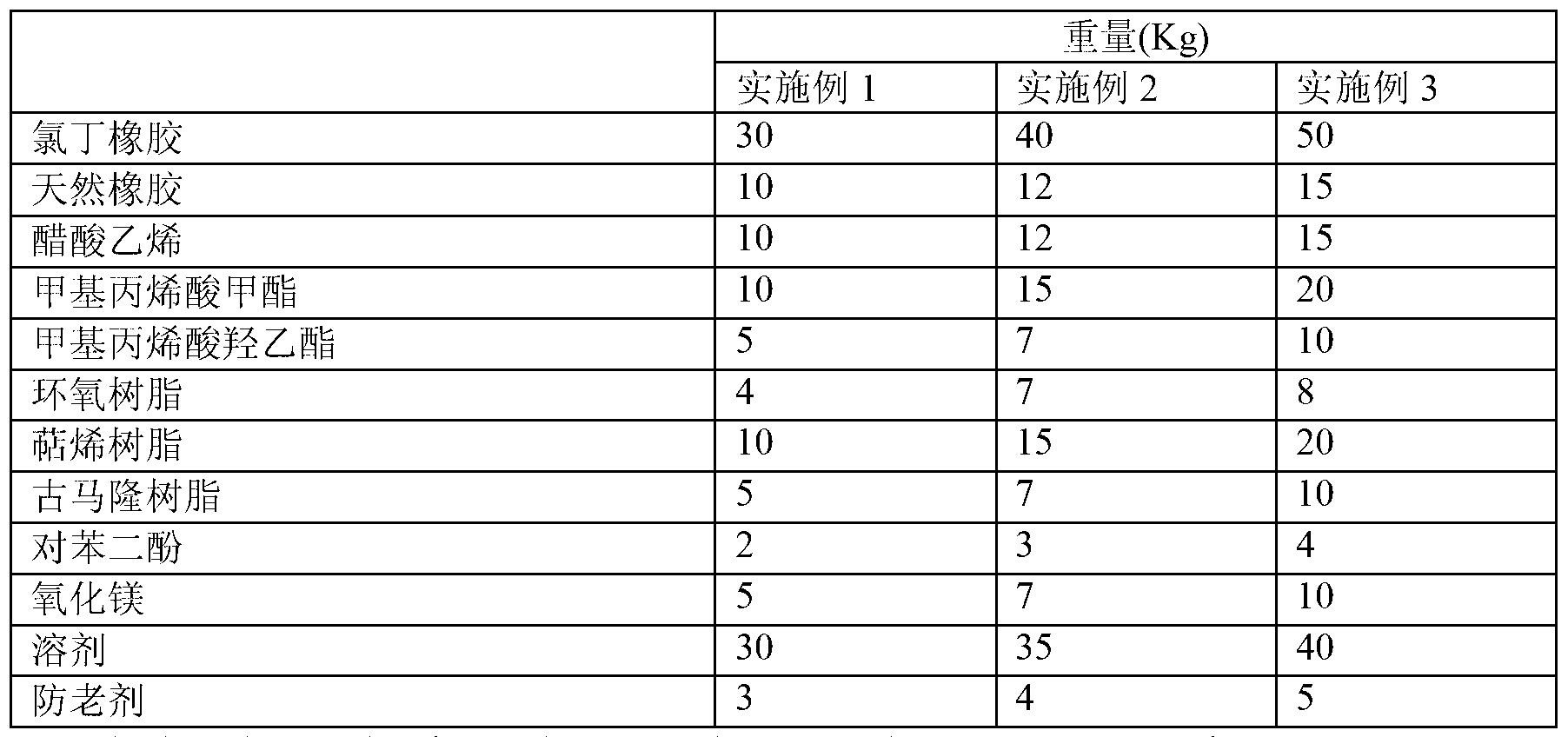

[0018] Prepare the raw materials of each embodiment according to the weight shown in Table 1.

[0019] The weight proportion of table 1 embodiment 1~embodiment 3

[0020]

[0021] In the above embodiments, the solvent is toluene, the anti-aging agent is anti-aging agent RD, the magnesium oxide is light magnesium oxide, and the particle size is preferably controlled at 20-200 microns.

[0022] The preparation method is:

[0023] S1: Mix epoxy resin, terpene resin, and coumarone resin with magnesium oxide for 1 hour at 35°C;

[0024] S2: Mix the mixture obtained in step S1, neoprene rubber, natural rubber, vinyl acetate, methyl methacrylate, and hydroxyethyl methacrylate at 130°C for 0.5 hours;

[0025] S3: Mix the mixture obtained in step S2 with hydroquinone, solvent, and anti-aging agent at 35° C. for 1 hour, and let it cool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com