Packaging structure for glass sealing electronic component

A technology for electronic components and packaging structures, applied in electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as poor mechanical shock resistance, glass breakage, affecting the air tightness of the package, and achieve low loss, lead wire The effect of passing the current to increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

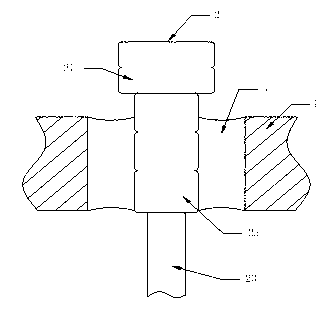

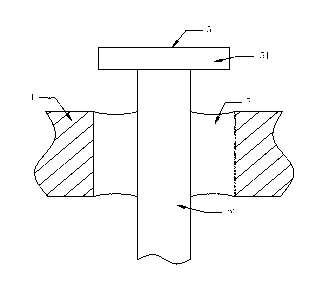

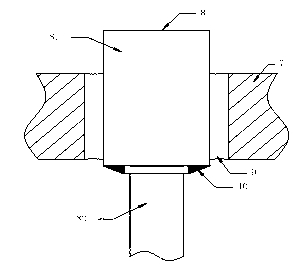

[0026] Such as figure 1 As shown, the packaging structure of the glass-encapsulated electronic components of this embodiment includes a metal substrate 7, and a sealing hole is arranged on the metal substrate 7, and a lead wire 8 is arranged in the sealing hole, and the lead wire 8 is connected to the wall of the sealing hole. Glass 9 is arranged between them, and the lead 8 includes an upper lead part 81 whose upper part is exposed on the surface of the metal substrate and the glass and passes through the sealing hole. The upper lead part 81 is a columnar structure, and the upper lead part 81 below The lower lead part 82 is connected, and the diameter of the upper lead part 81 is larger than that of the lower lead part 82; the edge of the joint between the lower lead part 82 and the upper lead part 81 is provided with a solder joint 10; in order to improve the strength and performance, The diameter of the upper lead portion 71 in this embodiment is greater than or equal to ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com