Centrifugal pendulum mechanism

A technology of centrifugal force pendulum and torque transmission device, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., and can solve the problem of large noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

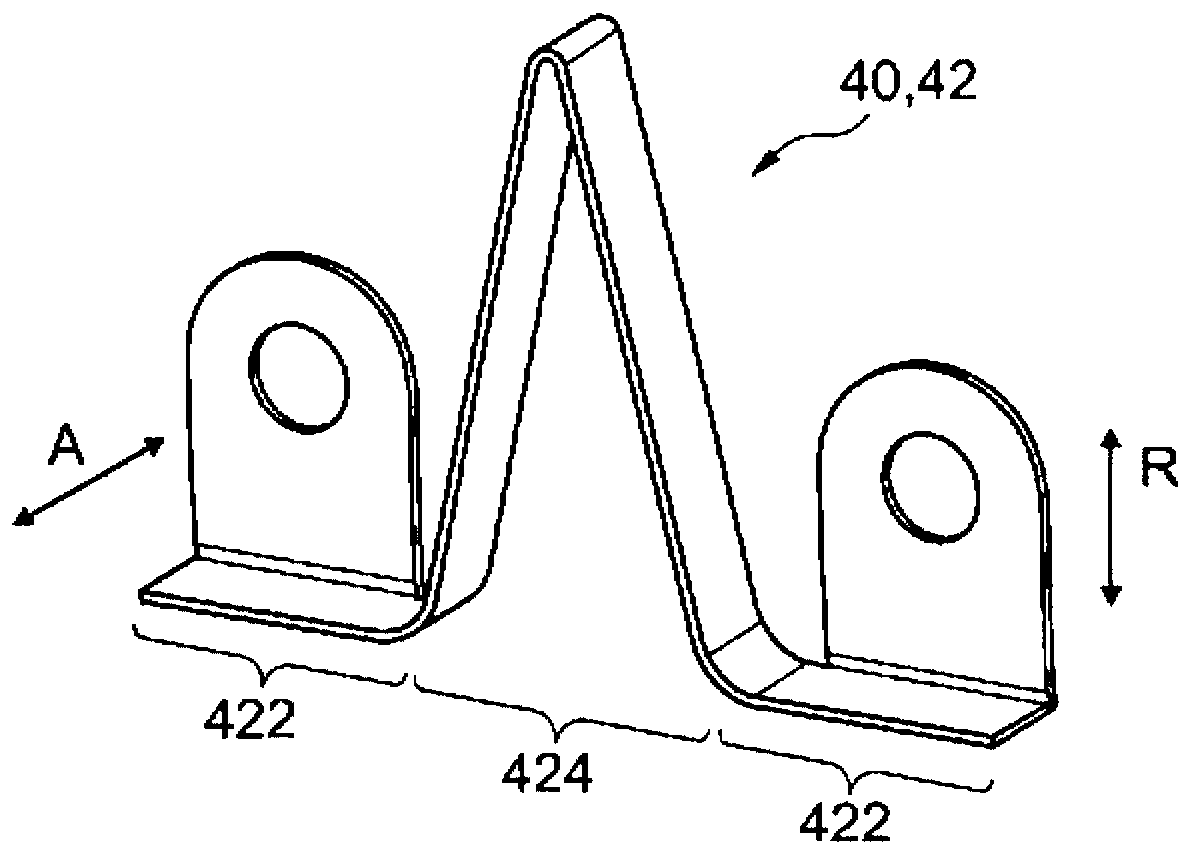

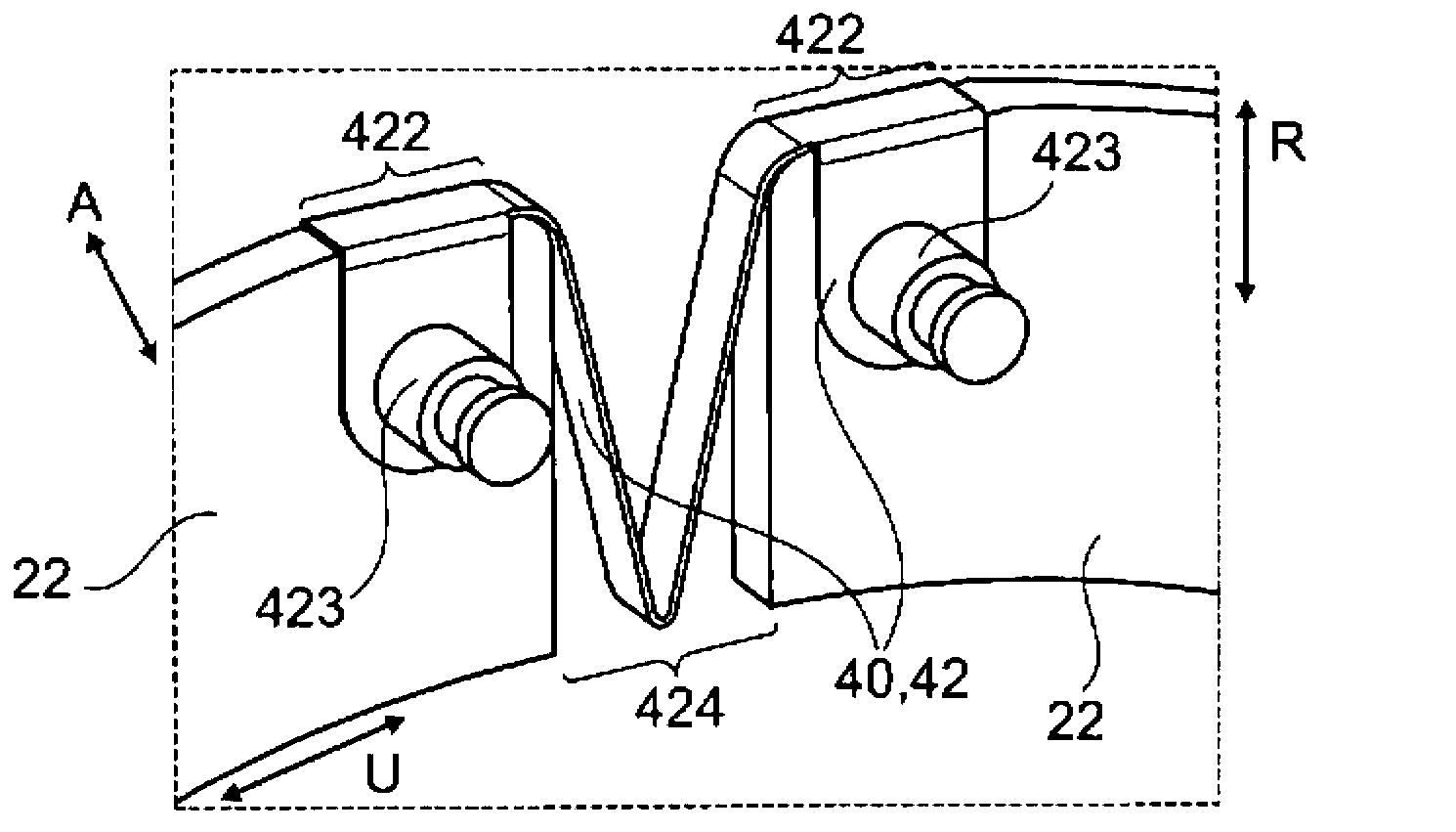

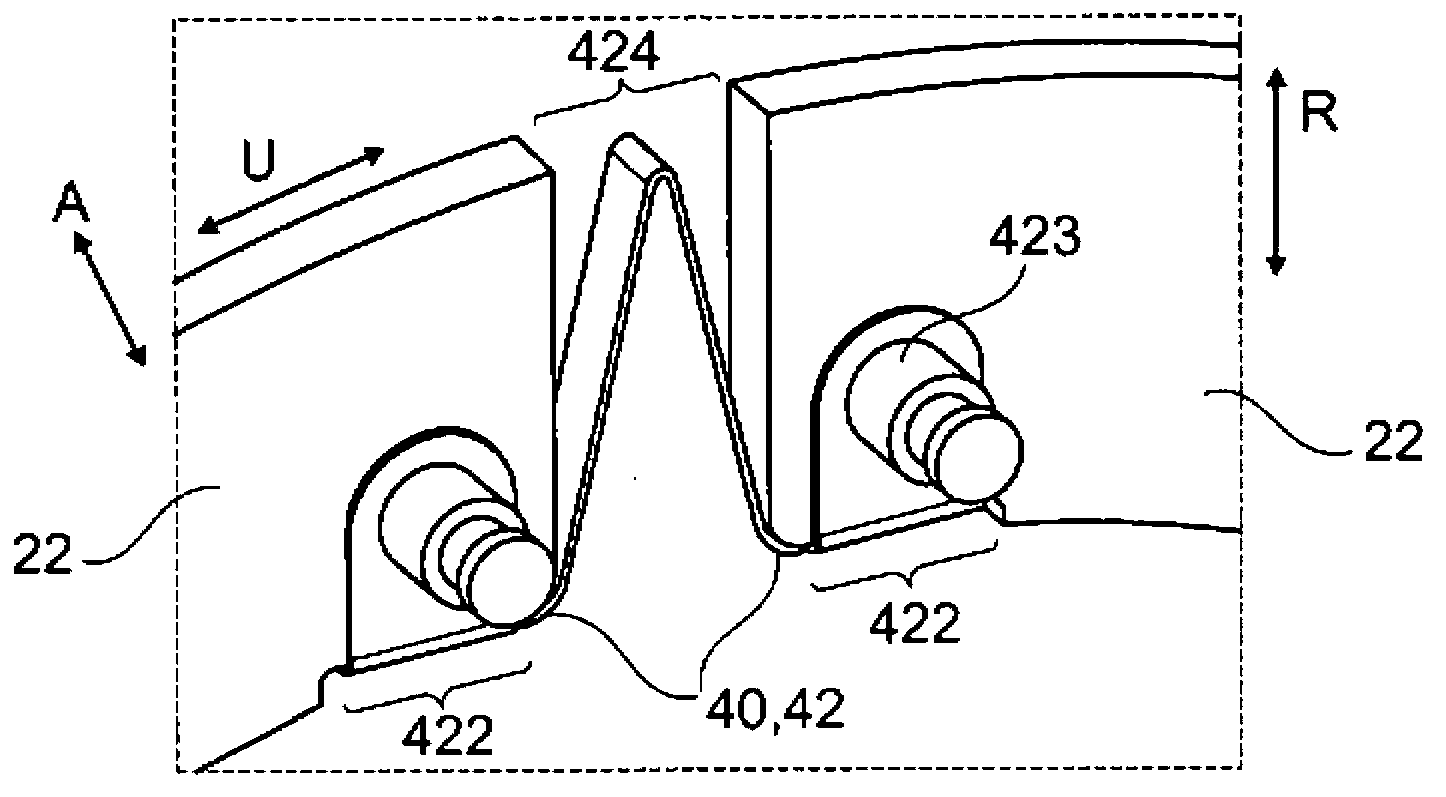

[0027] In a first embodiment of the first variant of the invention (see Figures 1 to 3 , and also Figures 7 to 10 ), the damping element 40 according to the invention for the centrifugal pendulum device 1 is configured as a spring element 42, the spring element 42 itself is designed as a leaf spring element 42 or a strip spring element 42, wherein the spring element 42 is configured at a certain The state or arrangement acts as a compression spring element 42 . In this case, the leaf spring element 42 is preferably made of a thin folded spring sheet, which is arranged on two directly adjacent Pendulum masses 22 or pairs of pendulum masses 20 are fastened there and in each case with fastening regions 422 . The spring region 424 of the leaf spring element 42 extends between two directly adjacent fastening regions 422 in the circumferential direction U, preferably only in certain states, namely in the pendulum mass 22 or the pendulum mass pair 20 With a defined relative posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com