Automatic manufacturing technology process of sports shoes

A technological process and technology for sports shoes, applied in the direction of shoe uppers, footwear, soles, etc., can solve the problems of inability to meet the requirements of mass production, single production products, complicated operations, etc., to save labor requirements, stabilize quality standards, and maintain stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

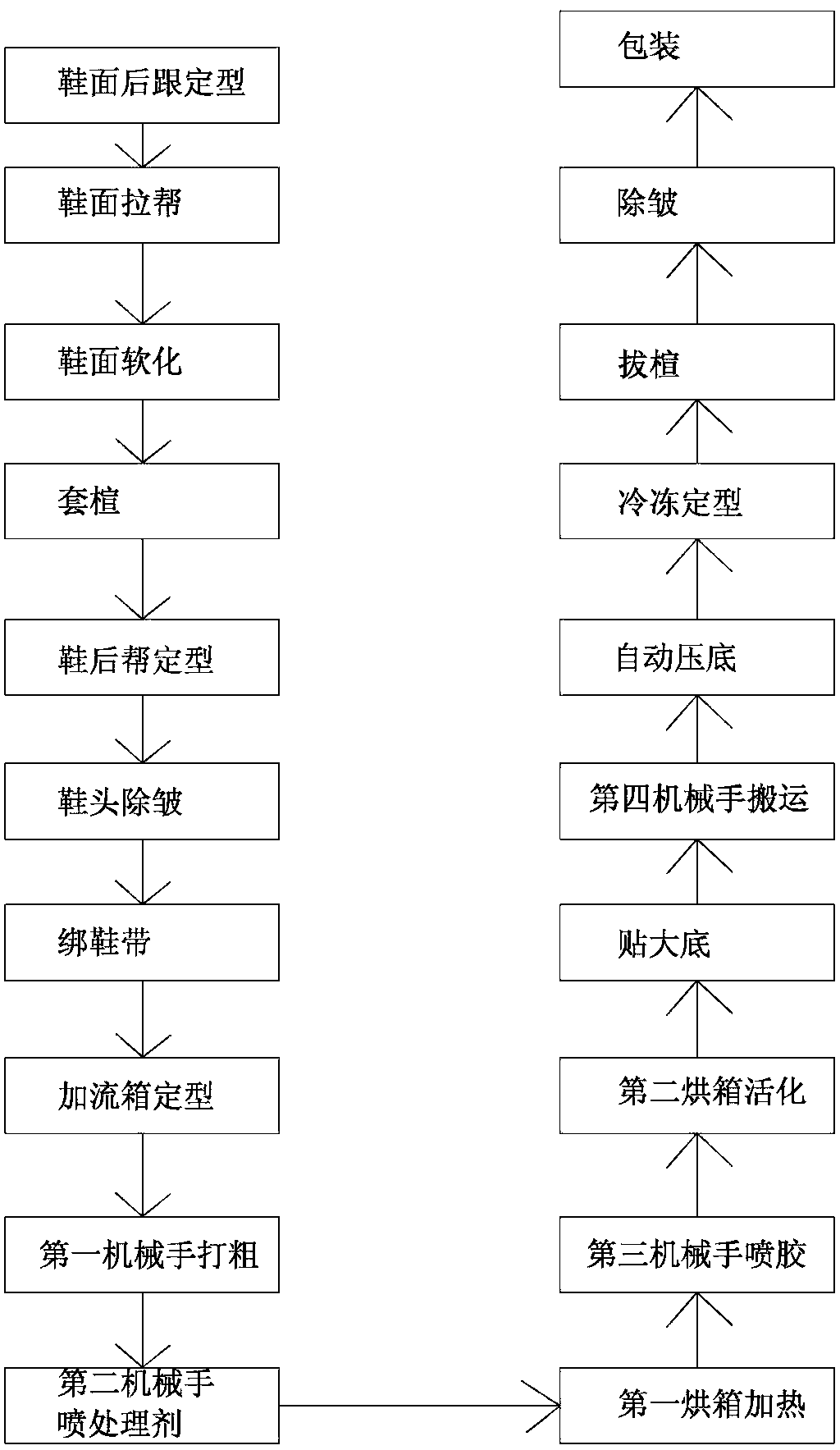

[0037] Embodiment one :Such as figure 1 Shown, a kind of sports shoes automatic manufacturing technological process comprises the following steps:

[0038] (1) The heel of the upper is shaped; the heel of the shoe is shaped to make the shape of the heel more in line with the foot shape; it is convenient for the operation in the later stage;

[0039] (2) Upper upper, the upper after the heel is finalized;

[0040] (3) The vamp is softened, and the vamp that needs to be lasted is softened by steam heating, and the softened vamp is easier to fit into the shoe last; the steam temperature for vamp softening is 100°C;

[0041] (4) Lasting, the shoe uppers softened by steam at 95°C are lasted, and the lasted shoe uppers are conveyed to the production line as a whole;

[0042] (5) The upper of the shoe is shaped, and the upper of the last is set to shape the upper;

[0043] (6) Toe cap wrinkle removal. To prevent the toe cap from wrinkling after the heel is shap...

Embodiment 2

[0059] Embodiment two :Such as figure 1 Shown, a kind of sports shoes automatic manufacturing technological process comprises the following steps:

[0060] (1) The heel of the upper is shaped; the heel of the shoe is shaped to make the shape of the heel more in line with the foot shape; it is convenient for the operation in the later stage;

[0061] (2) Upper upper, the upper after the heel is finalized;

[0062] (3) The vamp is softened, and the vamp that needs to be lasted is softened by steam heating, and the softened vamp is easier to fit into the shoe last; the steam temperature for vamp softening is 105°C;

[0063] (4) Lasting, the shoe uppers softened by steam at 100°C are lasted, and the lasted uppers are conveyed to the production line as a whole;

[0064] (5) The back of the shoe is shaped, and the upper of the last is set to shape the back of the shoe

[0065] (6) Toe cap wrinkle removal. To prevent the toe cap from wrinkling after the heel is...

Embodiment 3

[0081] Embodiment Three :Such as figure 1 Shown, a kind of sports shoes automatic manufacturing technological process comprises the following steps:

[0082] (1) The heel of the upper is shaped; the heel of the shoe is shaped to make the shape of the heel more in line with the foot shape; it is convenient for the operation in the later stage;

[0083] (2) Upper upper, the upper after the heel is finalized;

[0084] (3) The vamp is softened, and the vamp that needs to be lasted is softened by steam heating, and the softened vamp is easier to fit into the shoe last; the steam temperature for vamp softening is 110°C;

[0085] (4) Lasting, the shoe uppers softened by steam at 110°C are lasted, and the lasted uppers are conveyed to the production line as a whole;

[0086] (5) The back of the shoe is shaped, and the upper of the last is set to shape the back of the shoe

[0087] (6) Toe cap wrinkle removal. To prevent the toe cap from wrinkling after the heel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com